Discover how Huaneng Bearings turns "sticky" challenges into bespoke solutions. Hear the story of our European client’s tiny pulley, and how we go the extra mile for trust.

From "Stuck" to "Tailor-Made": Our Customized Journey at Huaneng Bearings "Can’t believe you actually made such a tiny pulley!" Last week, an engineer from a European window and door firm sounded thrilled over the phone, holding the sample we’d sent. That seemingly run-of-the-mill customized order? It’s a perfect example of how we’ve gone from fixing "sticky" problems to crafting *exactly* what clients need. Let me take you back three months.

This European company was updating their curtain hardware, and they needed a tiny pulley: 3mm inner hole, 12.5mm diameter. The pulley itself isn’t hard to find, but factories aren’t willing to use highest quality bearing steel and plastic coated? Few and far between. Their procurement manager, Mr Chen, vented when we first chatted: "We’ve checked loads of suppliers. Some say they can’t make the mould; others want thousands upfront for tooling. And none want to bother with a sample. We haven’t even tested it yet – why would we place a big order blindly?" Our team didn’t flinch at the specs. Instead, we thought: How can we tweak what we already make to fit this perfectly?

See, our standard moulds only go down to 4mm inner holes, and they’re U-shaped ,which makes machining trickier. But the client was clear: they needed a sample to check if it fit their zinc alloy housing, to test how smoothly it ran, and check noise levels. Only then would they sign for a big order. "We can’t make the client pay for uncertain products," we all agreed. So we shifted gear: if the mould can’t change much, let’s find workarounds in materials and craft.

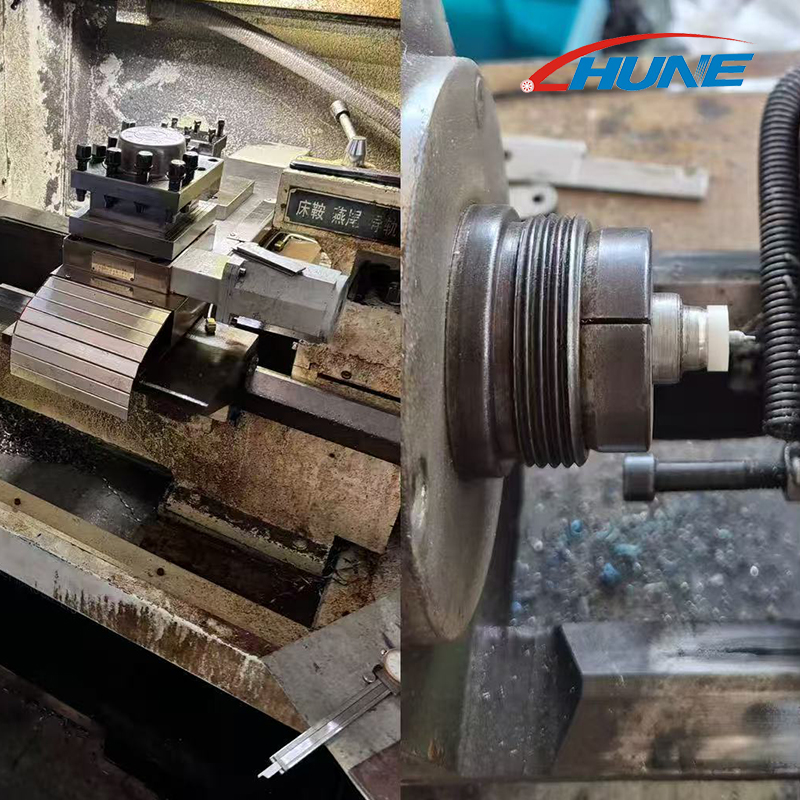

Our purchase team called suppliers that same day, rushing in 13mm POM plastic rod – tough stuff with low friction, perfect for the pulley’s outer ring. We slotted in a 693zz no-noise bearing, and that was the base. Next? It got hands-on.

In the workshop, Master Cai used a special sharpened tool to grind the mould’s groove bit by bit. The pulley’s so small, the groove depth could only be 0.6mm. "It’s like sharpening a chopstick – even a millimetre off, and it’s useless," he said. The adjusted mould just about held the material, and then we handed it to the CNC lathe: set the parameters, and let the machine shape an F-type pulley into a U-type. The sample was made!

We shipped the sample the same day – high efficiency is one of our strengths.,also.When the client got it, they said, "The finish, the size – it’s better than we hoped!" And the tests? Smooth as silk, no noise. Exactly what they needed. "Mind you, it’s not as good as the mass-produced version will be," Master Cai admitted. Machined pulleys aren’t as smooth as ones with plastic coating; they might wear faster long-term. But for a testing sample? It was more than enough to help them decide. Now, their first order’s rolling off our production line. We’re tweaking the new customized mould, and the mass-produced pulleys will use plastic coating for sturdier performance.

Mr Chen said when we signed: "You put this much effort into a tiny sample? We know we can trust you." Stories like this? They’re everyday at Huaneng. We get it – new clients always have that "let’s see" hesitation. So we’re happy to go the extra mile, even if it’s more hassle or costs a bit more. We want them to see our sincerity before we start. Trust isn’t just talked about – it’s built, one spot-on sample at a time. From unblocking "sticky" problems to crafting something *just for you*, we’re steady on this custom path.

Huaneng Bearings' costomized small pulley sample for European client.

English

English  Español

Español  日本語

日本語