The type of pulley can significantly impact a system's performance, efficiency, and lifespan. Pulleys are essential components in a wide range of applications, from industrial machinery to consumer goods, and understanding the differences between ball-bearing pulleys and standard pulleys is crucial to making the right choice.

Choosing the right pulley ensures smooth operation of your system, reducing friction, wear, and the need for ongoing maintenance. Whether you're designing a conveyor system, a manual lift mechanism, or a complex automotive installation, choosing the right pulley type ensures optimal load handling, operational efficiency, and long-term durability.

What Are Ball Bearing Pulley Wheels?

Ball Bearing Pulley Wheels are equipped with ball bearings, which allow them to rotate smoothly and with minimal friction. These pulleys are designed to support heavy loads while reducing the wear and tear that can occur from continuous movement. The ball bearings inside the pulley wheel enable smoother motion by providing an even distribution of force, which minimizes the friction between the rotating components.

Key Features of Ball Bearing Pulley Wheels:

- Reduced Friction: The ball bearings reduce the contact area between moving parts, resulting in less heat buildup and smoother rotation.

- High Load Capacity: Ball bearing pulleys are designed to handle heavier loads compared to plain pulleys, making them ideal for high-stress applications.

- Longer Lifespan: Because they experience less friction, ball bearing pulleys tend to last longer and require less maintenance over time.

Common Uses and Applications:

Ball bearing pulleys are ideal for heavy-duty and high-speed systems. They are commonly found in:

- Industrial machinery (e.g., conveyor belts, manufacturing equipment)

- Automotive applications (e.g., engine systems, timing belts)

- Material handling systems (e.g., cranes, hoists)

- Robotics (e.g., moving parts in robotic arms)

Ball bearing pulleys are best used in environments where performance and durability are critical, especially when the system is subject to heavy loads, high speeds, or frequent operation.

What Are Plain Pulley Wheels?

Plain Pulley Wheels, also known as simple pulleys, do not have ball bearings. Instead, they rely on a direct connection between the axle and the pulley, which can cause more friction during operation. Unlike ball bearing pulleys, plain pulleys are often used for lighter-duty applications where high speeds or heavy loads are not a concern.

Key Features of Plain Pulley Wheels:

- Higher Friction: The absence of ball bearings leads to greater friction during operation, which can cause wear over time.

- Cost-Effective: Plain pulleys are generally less expensive to produce and purchase than ball bearing pulleys.

- Simplicity: They are made of fewer components, making them easier to maintain in low-demand applications.

Common Uses and Applications:

Plain pulleys are ideal for light-duty systems where friction and wear are not a major concern. Common uses include:

- Manual systems (e.g., hand-operated winches, basic lifting mechanisms)

- Lightweight conveyor systems for non-industrial purposes

- Basic mechanical setups (e.g., garage doors, simple pulleys in farming equipment)

Plain pulleys are best suited for applications that don’t require high precision or load-bearing capacity. They are most commonly used in low-load applications or systems where simplicity and cost-effectiveness are more important than performance.

Advantages of Ball Bearing Pulley Wheels vs Plain Pulley Wheels

Understanding the advantages of each type (ball bearing pulleys and conventional pulleys) is crucial to optimizing performance, durability, and efficiency. Both types of pulleys are used across a wide range of industries, but each has its own advantages and is suitable for different applications.

Advantages of Ball Bearing Pulley Wheels

Ball bearing pulleys offer significant benefits that make them the preferred choice for high-performance and high-load applications.

1. Reduced Friction

The primary benefit of Ball Bearing Pulley Wheels is their ability to minimize friction. The ball bearings inside the pulley allow it to rotate smoothly, reducing the resistance between moving parts. This leads to less heat buildup, greater efficiency, and longer operational lifespan.

- Why It Matters: Reduced friction translates into lower energy consumption and improved overall system performance, making them ideal for high-speed and high-load applications.

2. High Load Capacity

Ball bearing pulleys are designed to handle heavier loads without compromising performance. The presence of ball bearings enables the pulley to distribute weight evenly, allowing it to carry more weight without experiencing excessive wear or deformation.

- Why It Matters: For industrial applications where large, heavy objects are frequently moved, the high load capacity of ball bearing pulleys ensures durability and consistent performance even under pressure.

3. Longer Lifespan

Because of the smooth operation and reduced friction, Ball Bearing Pulley Wheels generally last longer than plain pulleys. The ball bearings reduce wear and tear, extending the life of the pulley and requiring fewer replacements over time.

- Why It Matters: A longer lifespan reduces maintenance and replacement costs, making them a more cost-effective option in the long run.

4. Improved Speed and Efficiency

Ball bearings facilitate faster and more efficient rotation. This makes ball bearing pulleys ideal for applications that require quick movements or precise control, such as in conveyor belts, automated machinery, or lifting systems.

- Why It Matters: Systems that require high-speed operations will benefit from the smooth, frictionless movement that ball bearing pulleys provide, enhancing the overall productivity of your setup.

5. Better Performance in Harsh Environments

Ball bearing pulleys are built to withstand challenging operating conditions, including extreme temperatures, high humidity, and exposure to chemicals. Certain types of ball bearings are sealed or lubricated to ensure smooth operation even in tough environments.

- Why It Matters: For industries like manufacturing, construction, or material handling, where pulleys are subjected to harsh environmental conditions, ball bearing pulleys provide reliable, consistent performance.

Advantages of Plain Pulley Wheels

While Plain Pulley Wheels may not offer the same high-performance benefits as ball bearing pulleys, they come with their own set of advantages that make them suitable for specific applications.

1. Simple Design and Cost-Effective

Plain pulleys feature a simple, straightforward design with fewer components than ball bearing pulleys. This simplicity results in a lower manufacturing cost, making them a more affordable option for many applications.

- Why It Matters: If you're working with a budget or need a cost-effective solution for lighter-duty tasks, plain pulleys provide an economical choice without sacrificing basic functionality.

2. Suitable for Light-Duty Applications

Plain pulleys are well-suited for applications where the load is light and the system does not require high precision. These pulleys can effectively handle low to moderate loads and are often used in manual systems or simple mechanical setups.

- Why It Matters: For non-industrial or low-demand applications like small conveyor systems, manual winches, or pulley systems in farming equipment, plain pulleys offer sufficient performance without the added cost of ball bearings.

3. Easy Maintenance

Because they lack complex internal components like ball bearings, plain pulleys are relatively easy to maintain. There are fewer parts that can wear out or require replacement, and the pulley can often be cleaned or lubricated with minimal effort.

- Why It Matters: For systems that are infrequently used or don’t require high performance, plain pulleys offer low-maintenance operation, reducing the need for regular upkeep.

4. Less Vulnerable to Environmental Factors

Plain pulleys are less sensitive to the presence of dust, dirt, or moisture than ball bearing pulleys. While they may not be as durable in high-load or high-speed systems, their simple design can make them more resilient in environments where debris or contamination is a concern.

- Why It Matters: For applications in areas with minimal exposure to harsh conditions, plain pulleys can continue to operate reliably without the need for protective seals or lubrication, making them suitable for more casual or less demanding environments.

5. Versatility

Plain pulleys are versatile and can be used in a variety of applications, particularly in mechanical systems where high precision and load capacity aren’t as critical. They are commonly found in everyday tools, light-duty industrial applications, and DIY projects.

- Why It Matters: If you're building a small-scale or personal project, plain pulleys offer flexibility and simplicity without overcomplicating the system design.

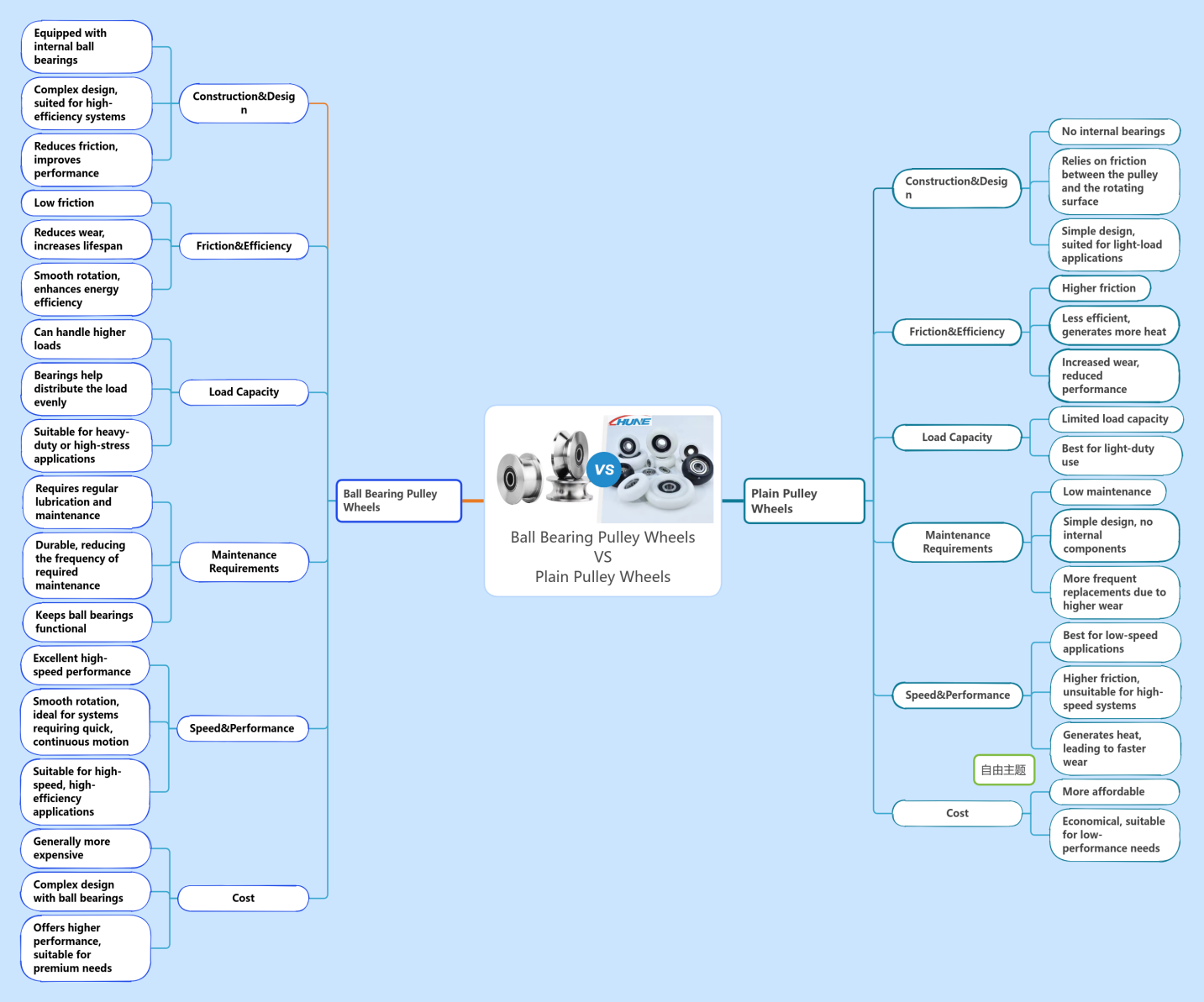

Key Differences Between Ball Bearing and Plain Pulley Wheels

1. Construction and Design

- Ball Bearing Pulley Wheels are equipped with ball bearings inside the pulley to reduce friction and improve performance.

- Plain Pulley Wheels have a simple design with no internal bearings. They rely on friction between the pulley and the rotating surface.

2. Friction and Efficiency

- Ball Bearing Pulley Wheels have low friction, allowing for smooth rotation and efficient energy use. This results in less wear on the pulley and other system components.

- Plain Pulley Wheels experience higher friction, leading to greater wear over time and less efficient operation, especially in high-load or high-speed environments.

3. Load Capacity

- Ball Bearing Pulley Wheels are built to handle much higher loads than plain pulleys. The bearings inside help distribute the load evenly, preventing premature wear or damage.

- Plain Pulley Wheels are limited in their load capacity due to their design. They are better suited for light-duty applications where the load is minimal.

4. Maintenance Requirements

- Ball Bearing Pulley Wheels require regular lubrication and occasional maintenance to ensure the ball bearings remain functional. However, their durability reduces the frequency of required maintenance.

- Plain Pulley Wheels are relatively low-maintenance because they have no internal components. However, due to higher friction, they may need to be replaced more often.

5. Speed and Performance

- Ball Bearing Pulley Wheels excel in high-speed applications. The smooth rotation provided by the bearings makes them ideal for systems requiring quick, continuous motion.

- Plain Pulley Wheels are best suited for low-speed applications. The increased friction makes them unsuitable for high-speed systems as they tend to generate more heat and wear out quicker.

6. Cost

- Ball Bearing Pulley Wheels are generally more expensive due to the added complexity of the ball bearings.

- Plain Pulley Wheels are more affordable, making them an economical choice for applications where high performance is not required.

Which One Should You Choose?

When to Use Ball Bearing Pulley Wheels

Heavy-Duty Applications: If you need to move heavy loads regularly, ball bearing pulleys are your best bet. Their load capacity and smooth operation make them ideal for industrial systems like conveyor belts, lifting systems, and heavy machinery.

- High-Speed Systems: For systems that require fast, continuous movement, ball bearing pulleys reduce friction and enhance speed without sacrificing performance.

- Harsh Environments: If the pulley will be exposed to chemicals, extreme temperatures, or humidity, ball bearing pulleys—especially those made with sealed or corrosion-resistant bearings—can withstand tough conditions without failing prematurely.

When to Use Plain Pulley Wheels

Light-Duty Applications: For systems with minimal load requirements, such as small conveyors or hand-operated systems, plain pulleys provide adequate performance at a lower cost.

- Cost-Effective Solutions: If you're working with a limited budget, plain pulleys are a more economical choice for low-demand applications.

- Low-Speed Systems: If your system doesn't require high speeds, plain pulleys can function well without the need for expensive ball bearings.

Performance Considerations for Ball Bearing Pulley Wheels vs Plain Pulley Wheels

Efficiency, load capacity and maintenance requirements will significantly affect the performance of a pulley system. These properties are key factors in selecting the right pulley.

Performance Considerations for Ball Bearing Pulley Wheels

- Smooth Rotation and Low Friction

- Ball bearing pulleys are designed to provide smooth rotation with minimal friction, which translates to more efficient operation. The ball bearings inside the pulley reduce the amount of energy lost to friction, leading to smoother and faster movement, especially under heavy loads.

- Higher Load Capacity

- Ball bearing pulleys can handle much higher loads compared to plain pulleys. The bearings inside help distribute the load evenly, preventing the pulley from wearing out quickly under pressure. This makes ball bearing pulleys ideal for heavy-duty applications like manufacturing, construction, and automotive systems.

- Durability and Longevity

- Ball bearing pulleys tend to have a longer lifespan due to the reduced friction and wear on internal components. In harsh conditions, sealed or shielded bearings offer protection against dust, dirt, and moisture, prolonging the pulley’s lifespan.

- Higher Speed

- Ball bearing pulleys are designed for high-speed operations. The low friction means the system can run continuously at faster speeds without overheating or wearing out prematurely. Applications like high-speed conveyor systems, sorting machines, or robotics will benefit from ball bearing pulleys.

- Maintenance

- Although ball bearing pulleys are low-maintenance compared to plain pulleys, they still require periodic lubrication and inspection to ensure the bearings remain in good condition. Well-maintained ball bearing pulleys can operate for thousands of hours without significant wear.

Performance Considerations for Plain Pulley Wheels

- Increased Friction

- Plain pulleys rely on the direct contact between the pulley and the axle or surface it rotates on. This creates more friction, which leads to increased energy loss and heat generation. As a result, plain pulleys are more suitable for low-speed systems that don’t require high efficiency.

- Lower Load Capacity

- Due to the lack of bearings, plain pulleys are not as efficient at handling heavy loads. They can work well for light-duty applications but will wear out more quickly when subjected to heavy pressure. Plain pulleys are ideal for applications with minimal load requirements.

- Less Durability

- Plain pulleys are more susceptible to wear and tear over time, especially in high-friction applications. The increased friction leads to faster degradation of the pulley and other system components, reducing the overall lifespan of the system.

- Ideal for Low-Speed Systems

- Since plain pulleys produce more friction, they are better suited for low-speed systems. Applications where fast or continuous movement is not required can benefit from plain pulleys, such as light-duty belt drives or simple mechanical systems.

- Minimal Maintenance

- Plain pulleys are low-maintenance due to their simple design. With fewer moving parts, they don't require lubrication or frequent inspection. However, because of higher friction and wear, they may need replacement sooner than ball bearing pulleys.

Comparison of Ball Bearing and Plain Pulley Wheels: Key Features and Benefits

|

Feature |

Ball Bearing Pulley Wheels |

Plain Pulley Wheels |

|

Smooth & Efficient |

Low friction, leading to smoother and faster movement. |

More friction, less efficient, generates heat and energy loss. |

|

Higher Load Capacity |

Can handle heavier loads without quick wear. |

Best for light-duty applications. |

|

Longer Lifespan |

Reduced friction means they last longer. |

Wears out quicker due to higher friction. |

|

Faster Speed |

Ideal for high-speed applications. |

Suitable for low-speed systems. |

|

Low Maintenance |

Requires occasional lubrication and inspection. |

Minimal maintenance but may wear out faster. |

Choosing the Right Pulley for Your Needs

Deciding between ball bearing pulleys and conventional pulleys depends on your specific performance requirements, budget, and the operating environment of your pulley system.

Ball bearing pulleys are ideal for heavy-duty, high-speed, and high-load applications where durability, smooth operation, and low friction are critical.

Conventional pulleys are better suited for lighter-duty applications, slow-speed systems, and budget-conscious projects where cost is prioritized over high performance.

By understanding the key performance differences, you can make an informed decision and select the right pulley to ensure your system operates smoothly and efficiently for the long term.

English

English  Español

Español  日本語

日本語