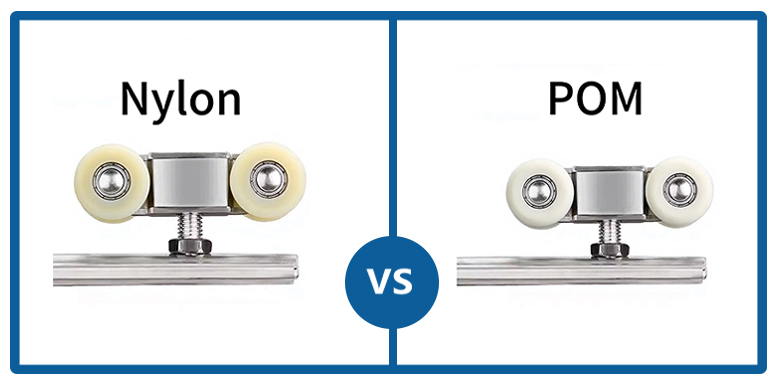

Have you ever had a window or door pulley fail? The squeaks, the sticking, the frustrating grind as you try to open a heavy door. It's a common problem, and it usually comes down to one thing: the material. Choosing the right plastic coated pulley material is key for smooth operation and long-lasting performance. In the world of pulleys, two materials often come up: nylon and POM. This article will help you understand the differences in nylon pulley vs pom, so you can make the right choice.

Understanding Plastic Coated Pulley Material

Plastic pulleys are common for a reason. They offer quiet operation and are self-lubricating, which reduces friction. But not all plastics are equal. We will look at what makes nylon and POM different and how these differences affect their performance.

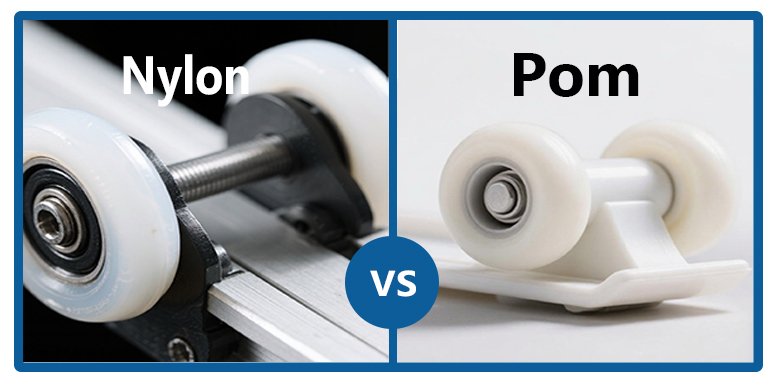

Nylon Pulley: Nylon, a type of polyamide, is known for its strength and flexibility. It handles high-impact loads well and resists abrasion. This makes it a great choice for pulleys that see a lot of use.

POM Pulley: POM, or polyoxymethylene, is a different kind of plastic. It is harder and more rigid than nylon. POM offers excellent dimensional stability, meaning it holds its shape very well under stress. This can be important for precision applications.

Let's break down the key differences in a table.

|

Feature |

Nylon |

POM (Delrin) |

|

Mechanical Properties |

High tensile strength, good impact resistance |

High stiffness, excellent dimensional stability |

|

Hardness |

Softer than POM, more flexible |

Harder and more rigid |

|

Friction |

Low friction, self-lubricating |

Very low friction, excellent wear resistance |

|

Abrasion Resistance |

Good |

Excellent |

|

Moisture Absorption |

Can absorb moisture, which may affect dimensions |

Low moisture absorption, more stable |

|

Temperature Range |

Wide operating temperature range |

Good thermal stability |

|

Cost |

Generally more affordable |

Slightly more expensive |

Bearing Material for Pulleys: The Hidden Hero

The pulley's bearing is just as important as the material. The right bearing ensures the pulley spins freely and quietly. The wrong bearing can lead to early failure. Here's a look at common bearing material for pulleys.

Stainless Steel Bearings: These are ideal for pulleys used in damp or outdoor environments. Stainless steel resists rust and corrosion, extending the pulley's life. Think about pulleys for sliding doors leading to a garden or balcony.

Carbon Steel Bearings: Carbon steel is a strong and affordable option. It works well for indoor pulleys where moisture is not a concern. These bearings are often lubricated with grease to reduce friction and noise.

Ceramic Bearings: Ceramic bearings are a premium choice. They are lighter, spin faster, and have a longer life than steel bearings. They are also non-magnetic and highly resistant to corrosion. While they are more expensive, they are perfect for high-performance pulleys.

Pulley Durability Test: How Do They Hold Up?

We all want pulleys that last. A pulley durability test shows us how these materials perform under stress. Nylon pulleys are known for their ability to handle impact without cracking. The material's flexibility allows it to absorb shock. This is great for doors that might be slammed shut.

POM pulleys, with their rigidity, offer high resistance to wear and abrasion. The hard surface of a POM pulley resists scratching and wearing down over time. This makes them excellent for applications with continuous movement, such as garage doors or heavy sliding windows.

For a pulley to pass a durability test, it must withstand thousands of cycles without significant wear. Both nylon and POM pulleys can pass this test, but their strengths lie in different areas. Nylon is a good all-rounder, while POM shines in applications where precision and wear resistance are top priorities.

The Right Pulley for the Job: Nylon vs. POM

Choosing between a nylon and a POM pulley depends on the specific use.

Choose Nylon for:

Doors and windows that experience impact.

Applications where flexibility is an asset.

Cost-effective projects.

A good balance of strength and durability.

Choose POM for:

Precision machinery.

Heavy-duty sliding doors and gates.

Environments with continuous movement.

When high wear resistance is the main concern.

Remember, the bearing material for pulleys also plays a big role. A nylon pulley with a high-quality stainless steel bearing will outperform a POM pulley with a low-grade carbon steel bearing in a humid environment.

Making the Right Choice for Your Home

When I am looking at replacing a pulley, I first consider where it will be used. For an indoor wardrobe door, a simple nylon pulley with a carbon steel bearing is often a perfect fit. It's affordable and will last for years. For an outdoor patio sliding door, I would lean towards a POM pulley with a stainless steel bearing. The extra cost is worth it for the added durability and resistance to the elements.

This choice is not just about the material; it's about the combination of plastic coated pulley material and the bearing. Both parts work together to give you a smooth, quiet, and reliable operation.

Frequently Asked Questions (FAQs)

Q1: What is the main difference between nylon and POM pulleys?

A: Nylon is more flexible and has higher impact resistance. POM is harder, more rigid, and offers excellent wear resistance.

Q2: Is a metal pulley better than a plastic one?

A: Not always. Plastic pulleys, especially those made from nylon or POM, are self-lubricating and operate more quietly than metal pulleys. They are also lighter and resist corrosion.

Q3: How do I know if my pulley needs replacing?

A: A pulley needs replacing if it is squeaking, sticking, or visibly worn down. You might also see cracks or chips in the plastic.

Q4: Does the bearing material matter?

A: Yes, the bearing material for pulleys is very important. Stainless steel bearings are best for wet areas, while carbon steel bearings are fine for dry indoor use.

Q5: What is a pulley durability test?

A: A pulley durability test checks how a pulley performs under repeated use. It measures how many cycles a pulley can go through before it shows significant wear or fails.

Choosing between a nylon pulley vs pom is a key decision for any window or door repair. Understanding the differences in these materials helps you pick the right part for a long-lasting fix.

English

English  Español

Español  日本語

日本語