Small bearings, such as the 626 series, are integral to a wide range of mechanical systems and machinery due to their versatility, compact size, and ability to handle high-speed rotations with minimal friction. These bearings are designed to support both radial and axial loads in smaller, more confined spaces, making them ideal for applications where space is limited or where low friction is crucial.

Understanding bearing codes like Z and ZZ is crucial when selecting the right bearing for a specific application. Bearing codes provide a wealth of information about the design, sealing, and shielding of the bearing, allowing engineers and buyers to make informed decisions based on the demands of the machinery or equipment.

How Bearing Codes Work:

Z and ZZ are part of the standardized shielding and sealing codes used in bearing designations.

The code 626Z means a single metal shield on one side of the bearing, while 626ZZ indicates metal shields on both sides.

What Does "626" Mean in Bearing Terminology?

The 626 is a specific code within the ISO standard bearing system. Here's a breakdown of what each part of the code represents:

6: Represents the bearing series or type. In this case, the "6" refers to the small-sized deep groove ball bearings, which are the most commonly used type of ball bearing.

2: The number "2" in the middle of the code often indicates the bearing's radial width, which is relatively narrow for this series.

6: The final "6" denotes the specific size or dimension of the bearing. This allows the manufacturer to differentiate between different bearing sizes under the same series.

Inner Diameter, Outer Diameter, and Width:

Each bearing in the 626 series has precise dimensional specifications:

Inner Diameter (ID): Typically 6 mm for the 626 series, though other diameters exist based on the bearing type.

Outer Diameter (OD): The outer diameter is usually 19 mm.

Width: The width of a 626 bearing is generally 6 mm.

These precise measurements make 626 bearings compatible with a variety of applications where space is constrained but performance is still critical.

Material Options for 626 Bearings

The materials used for 626 bearings significantly affect their performance, durability, and cost.

1. Chrome Steel (GCr15)

Properties: High hardness, good wear resistance, and durability.

Applications: Widely used in general industrial applications such as automotive components, home appliances, and machinery.

2. Stainless Steel (AISI 440C)

Properties: Corrosion resistance, ideal for harsh environments where moisture or chemicals might be present.

Applications: Suitable for medical equipment, food processing machinery, and outdoor applications.

3. Hybrid Ceramic Bearings

Properties: Ceramic balls and steel races provide superior performance with reduced friction, longer service life, and higher resistance to heat.

Applications: Ideal for high-speed applications in industries like aerospace, medical, and robotics.

What Is 626Z Bearing?

A 626Z bearing is a small, deep groove ball bearing designed to handle radial loads and moderate axial loads. The Z in the bearing code refers to a single metal shield placed on one side of the bearing. This metal shield helps protect the internal components of the bearing from dust, dirt, and other contaminants, ensuring smoother operation and a longer service life.

Key Features of 626Z Bearing:

Shielding: A single metal shield on one side, which allows for effective contamination protection while enabling easy lubrication.

Size: The typical 626Z bearing has a 6mm inner diameter, a 19mm outer diameter, and a 6mm width, making it ideal for applications with limited space.

Material Options: Most commonly made of chrome steel, but stainless steel and ceramic variants are also available for specialized needs.

What Is 626ZZ Bearing?

A 626ZZ bearing is similar to the 626Z bearing, but it differs by featuring metal shields on both sides. These shields help provide an additional level of protection by preventing the ingress of dust, debris, and moisture from both sides, which enhances its durability and performance in challenging environments.

Key Features of 626ZZ Bearing:

Shielding: Double metal shields on both sides, offering superior protection against contaminants compared to the 626Z bearing.

Size: Like the 626Z, the 626ZZ bearing also typically features 6mm inner diameter, 19mm outer diameter, and 6mm width.

Material Options: Available in chrome steel, stainless steel, or ceramic, with the same material benefits as the 626Z bearing.

| Feature | 626Z Bearing | 626ZZ Bearing |

|---|---|---|

| Shielding | Single metal shield on one side | Double metal shields on both sides |

| Contamination Protection | Moderate protection from dust, dirt, and debris | Superior protection from dust, dirt, and debris |

| Size | 6mm inner diameter, 19mm outer diameter, 6mm width | 6mm inner diameter, 19mm outer diameter, 6mm width |

| Material Options | Chrome steel (most common), stainless steel, ceramic | Chrome steel, stainless steel, ceramic |

| Lubrication | Easy lubrication due to single shield | Better lubrication retention due to double shields |

| Applications | Ideal for compact machinery with moderate protection | Better for harsh environments requiring high protection |

| Durability | Suitable for less demanding applications | Enhanced durability for challenging environments |

Pros and Cons of 626Z Bearings

Pros:

Cost-Effective: 626Z bearings are generally more affordable compared to their double-shielded counterparts. This makes them a great option for budget-conscious projects or high-volume applications.

Easy Lubrication: The single shield allows for easy lubrication, which is important in low-maintenance applications.

Compact Design: Small size and lightweight make them ideal for compact machinery and space-constrained applications.

Moderate Protection: The metal shield provides adequate protection against contaminants on one side, making them suitable for environments where contamination levels are relatively low.

Cons:

Limited Protection: The single shield limits the bearing's ability to protect against contaminants from both sides, which may lead to a shorter lifespan in harsh environments.

Reduced Lubrication Retention: Compared to fully sealed bearings, 626Z bearings may lose lubrication more quickly, reducing performance over time if not properly maintained.

Not Ideal for High-Dust Environments: In dusty or wet conditions, the 626Z may not offer enough protection to prevent premature wear or damage.

Pros and Cons of 626ZZ Bearings

Pros:

Superior Contaminant Protection: With metal shields on both sides, the 626ZZ bearing offers better protection against dirt, moisture, and debris, which extends its lifespan and reduces maintenance needs.

Improved Lubrication Retention: The dual shields help retain lubrication within the bearing, which minimizes friction and wear.

Ideal for Harsh Environments: The double shielding makes the 626ZZ bearing an excellent choice for applications in more demanding environments, such as outdoors or in manufacturing processes.

Higher Durability: With the added protection, these bearings tend to last longer, especially in heavy-duty applications or high-speed operations.

Cons:

Higher Cost: Due to the added shielding and superior protection, 626ZZ bearings are typically more expensive than 626Z bearings.

More Friction: While the extra shields provide better protection, they may slightly increase friction, which could affect performance in applications requiring ultra-low friction.

Potential for Overheating: If used in high-speed applications where friction is a critical factor, the additional shields may lead to increased temperatures in the bearing, potentially causing overheating over time.

| Feature | 626Z Bearings | 626ZZ Bearings |

|---|---|---|

| Pros | ||

| Cost-Effective | More affordable compared to double-shielded bearings, ideal for budget-conscious or high-volume applications | More expensive due to additional shielding, ideal for demanding applications |

| Lubrication | Easy lubrication, suitable for low-maintenance applications | Improved lubrication retention due to double shields, minimizing friction and wear |

| Compact Design | Small size and lightweight, perfect for space-constrained machinery | Larger design due to extra shields, but still compact for many applications |

| Protection | Moderate protection from contaminants on one side, ideal for low-contaminant environments | Superior protection from dirt, moisture, and debris on both sides, extending lifespan and reducing maintenance needs |

| Cons | ||

| Limited Protection | Single shield limits protection against contaminants from both sides, reducing lifespan in harsh environments | Extra shields provide better protection, making it more durable in tough environments |

| Lubrication Retention | May lose lubrication faster compared to fully sealed bearings, requiring regular maintenance | Better lubrication retention, reducing the need for frequent maintenance |

| Dust and Moisture Protection | Not ideal for dusty or wet conditions, as the single shield can’t fully protect against contaminants | Better for high-dust or wet conditions due to dual shielding offering enhanced protection |

| Friction | - | Slight increase in friction due to additional shields, which can affect performance in low-friction applications |

| Overheating | - | Potential for overheating in high-speed applications due to increased friction |

626Z Bearing Maintenance Considerations

Proper maintenance is essential to ensure that the 626Z bearing performs optimally over time. Here are some key maintenance considerations:

Lubrication: While 626Z bearings come with a metal shield on one side, they should still be lubricated periodically to reduce friction and ensure smooth rotation. It's essential to use the right type of lubricant (grease or oil) and apply it to the bearing according to the manufacturer's guidelines.

Cleaning: Regular cleaning is necessary to remove any accumulated dust, dirt, or contaminants. Since the 626Z has a single shield, contaminants can still enter from the unshielded side if the environment is particularly harsh.

Environment: If the bearing operates in a dusty or moist environment, it may require more frequent maintenance. Consider moving the system to a cleaner area or using additional protective covers.

Inspection: Routinely inspect the bearing for signs of wear or damage, such as increased noise, reduced performance, or abnormal vibrations. Replace the bearing if you notice any of these issues to prevent further damage to surrounding components.

Replacement: Bearings should be replaced when they begin to show signs of fatigue or wear. This helps prevent further damage to machinery and ensures efficient operation.

626ZZ Bearing Maintenance Considerations

The 626ZZ bearing requires slightly different maintenance practices due to its double shielding. Here are the key considerations for maintaining a 626ZZ bearing:

Lubrication: Although 626ZZ bearings have a metal shield on both sides, they still require regular lubrication. Double-shielded bearings can retain grease better, but it is essential to check the lubrication periodically to ensure it is in good condition.

Cleaning: While the double shielding offers better protection against contaminants, it's still crucial to clean the bearings periodically to remove any debris or buildup. A build-up of contaminants inside the shields can increase friction and reduce performance.

Temperature Control: Ensure that the operating temperature of the bearing does not exceed recommended limits. Although 626ZZ bearings are durable, excessive friction can lead to overheating, particularly in high-speed applications.

Inspection: Regularly inspect the bearing for any signs of wear, damage, or corrosion, especially if it's used in challenging conditions such as moisture or chemical exposure. The shields should be checked to ensure they are intact and properly seated.

Storage: If the bearing is not in use, store it in a clean, dry area to prevent contaminants from entering the shielded areas. Proper storage extends the bearing's shelf life and ensures optimal performance once installed.

| Maintenance Aspect | 626Z Bearing Maintenance Considerations | 626ZZ Bearing Maintenance Considerations |

|---|---|---|

| Lubrication | Periodic lubrication to reduce friction and ensure smooth operation. Use the appropriate lubricant (grease or oil) as per manufacturer guidelines. | Requires regular lubrication as well, but better grease retention due to double shields. Check periodically to ensure the lubricant is in good condition. |

| Cleaning | Regular cleaning is essential to remove dust, dirt, or contaminants. Contaminants can enter from the unshielded side in harsh environments. | While the double shields offer better protection, it’s still important to clean periodically to avoid friction buildup from contaminants inside the shields. |

| Environment | In dusty or moist environments, more frequent maintenance is required. Consider using protective covers or moving to a cleaner environment. | Better protection in challenging environments, but still requires periodic maintenance to ensure optimal performance. |

| Temperature Control | - | Ensure operating temperature does not exceed recommended limits. Overheating can occur in high-speed applications due to increased friction. |

| Inspection | Routinely inspect for wear, noise, or abnormal vibrations. Replace bearings if any issues arise to prevent further damage to surrounding components. | Inspect regularly for wear, damage, corrosion, or seal integrity. Pay attention to the shields to ensure they remain intact. |

| Storage | - | Store in a clean, dry area when not in use to prevent contaminants from entering the shielded areas. Proper storage extends bearing lifespan. |

| Replacement | Replace when signs of fatigue or wear are noticed to prevent further damage and maintain efficient operation. | Replace when wear, damage, or corrosion is detected. Ensure to check the shields for integrity. |

Key Differences Between 626Z and 626ZZ Bearings

1. Shielding: One Side vs Both Sides

The most significant difference between 626Z and 626ZZ bearings lies in their shielding design.

626Z Bearing: This bearing features a single metal shield on one side. The shield provides some protection from dust and debris entering the bearing, but it leaves the other side open. This is suitable for applications in cleaner environments where contamination levels are relatively low.

626ZZ Bearing: This bearing has metal shields on both sides. This dual shielding offers superior protection by preventing contaminants from entering the bearing from either side. It is especially useful in environments exposed to dust, dirt, moisture, or other harsh elements.

Key Takeaway: If you require higher protection, especially in harsh or contaminated environments, 626ZZ bearings are the better choice due to their double shielding.

2. Dust Protection and Contamination Resistance

626Z Bearing: The single shield on one side provides moderate protection against dust and debris. However, the unshielded side allows contaminants to enter if the environment is dusty or moist. Therefore, 626Z bearings are more suitable for low-contamination environments or applications where bearings are regularly maintained.

626ZZ Bearing: With metal shields on both sides, the 626ZZ bearing offers higher contamination resistance. It is better suited for environments where dust, dirt, or moisture could affect the bearing's performance. The double shields prevent external contaminants from entering, providing superior protection against dirt and water.

Key Takeaway: If your application operates in dusty, dirty, or wet conditions, the 626ZZ bearing offers significantly better protection and longevity.

3. Lubrication Retention Ability

626Z Bearing: The single shield on the 626Z bearing allows for easier lubrication and makes it easier to apply grease or oil directly into the bearing. However, since it only has protection on one side, it may lose lubrication over time, especially in high-speed applications or environments with contaminants. Frequent lubrication may be required to maintain optimal performance.

626ZZ Bearing: The double shields of the 626ZZ bearing help retain lubrication more effectively. The shields reduce the loss of grease or oil, ensuring that the bearing maintains its optimal lubrication for longer periods. This is particularly beneficial for high-speed operations or applications where lubrication needs to last longer without frequent maintenance.

Key Takeaway: 626ZZ bearings generally offer better lubrication retention, which can reduce maintenance costs and downtime in many industrial and mechanical applications.

4. Friction and Speed Performance

626Z Bearing: Since the 626Z bearing has only a single shield, there is less friction compared to double-shielded bearings. This makes it more suitable for applications requiring lower friction, such as in toys, small motors, or devices where speed and smooth movement are prioritized.

626ZZ Bearing: While the double shielding provides better protection, it can lead to slightly higher friction due to the added material. This may cause a reduction in performance in applications where ultra-low friction is essential. However, the added shielding helps in maintaining consistent performance in demanding environments.

Key Takeaway: If speed and low friction are critical factors in your application, the 626Z bearing might be the better option. For environments where protection outweighs the slight increase in friction, the 626ZZ bearing is ideal.

5. Cost Differences

626Z Bearing: Due to its simpler design (single shield), 626Z bearings are generally more cost-effective than their 626ZZ counterparts. They are a popular choice in applications where the environment is not too harsh, and contamination protection requirements are lower.

626ZZ Bearing: The additional metal shield on both sides of the 626ZZ bearing makes it more expensive than the 626Z bearing. However, this additional cost provides better protection, making the 626ZZ bearing worth the investment in environments with high contamination risks or higher operational demands.

Key Takeaway: If budget is a primary concern and you don't require the extra protection, the 626Z bearing is the more cost-effective option. For critical applications, however, the added cost of the 626ZZ bearing is justified by its superior protection and durability.

6. Lifespan in Different Environments

626Z Bearing: The lifespan of the 626Z bearing can be significantly reduced in harsh environments, especially those that are dusty, wet, or where the bearing is exposed to high levels of contamination. Since the bearing only has a single shield, contaminants can enter more easily, leading to quicker wear and potential failure.

626ZZ Bearing: Thanks to its double shielding, the 626ZZ bearing typically lasts longer in environments with high dust, moisture, or chemical exposure. The double shields provide more effective protection, extending the bearing's service life and reducing the frequency of maintenance or replacements.

Key Takeaway: In environments where contaminants are a concern, 626ZZ bearings will last longer due to their double shielding and superior protection. For cleaner environments, 626Z bearings may be sufficient and offer a longer lifespan at a lower cost.

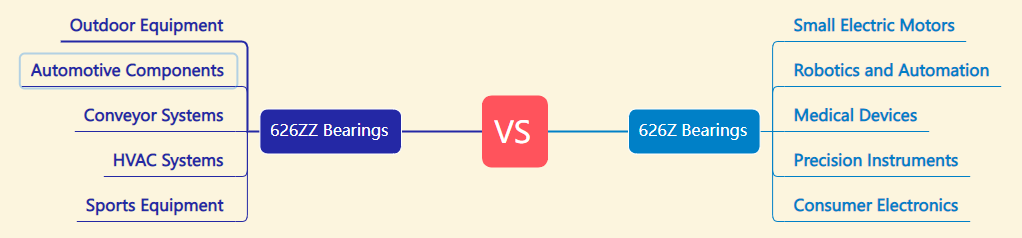

Applications of 626Z Bearings

The 626Z bearing is commonly used in various applications where moderate protection and low maintenance are required. Due to its single metal shield on one side, the 626Z bearing is ideal for environments with low contamination levels and applications where space constraints and smooth operation are priorities.

Key Applications of 626Z Bearings:

Small Electric Motors:

The 626Z bearing is often used in small motors, such as those in household appliances (e.g., blenders, vacuums, fans) and toys. These applications benefit from the bearing's compact size and efficient operation at moderate speeds.

Robotics and Automation:

In robotic arms and automation systems, 626Z bearings provide smooth rotation while maintaining a compact design, making them suitable for tight spaces and high-speed movement.

Medical Devices:

The 626Z is used in medical devices that require precision and reliability, such as scanners, surgical tools, and other high-precision equipment where space and low friction are critical.

Precision Instruments:

Found in measuring tools, gauges, and other precision equipment, 626Z bearings offer the necessary balance of speed and compactness, suitable for applications requiring smooth and accurate movement.

Consumer Electronics:

Bearings are used in devices like printers, gaming consoles, and cameras, where low friction and efficient performance are essential for everyday usage.

Applications of 626ZZ Bearings

The 626ZZ bearing, with metal shields on both sides, offers enhanced protection against contaminants, making it suitable for more demanding applications and harsher environments.

Key Applications of 626ZZ Bearings:

Outdoor Equipment:

The 626ZZ bearing excels in outdoor applications, such as bicycles, motorcycles, and garden machinery, where exposure to dust, water, and chemicals is common. The double shielding protects the bearing in challenging environments.

Automotive Components:

Automotive systems, like power windows, wipers, and fans, often use 626ZZ bearings for better protection against contaminants and to ensure smoother operation in harsh conditions.

Conveyor Systems:

Industrial conveyor belts and material handling systems benefit from 626ZZ bearings, which offer superior contamination resistance, ensuring longer operational life in factories and warehouses with dusty or humid environments.

HVAC Systems:

Bearings in air conditioning units, fans, and ventilation systems benefit from the 626ZZ's double shielding, ensuring durability in environments that may have high humidity or airborne particles.

Sports Equipment:

In skateboards, rollerblades, and electric scooters, 626ZZ bearings are used for their durability, providing smooth motion even in dusty or wet conditions.

How to Choose Between 626Z and 626ZZ Bearings

Choosing the right bearing type depends on multiple factors, including the operating environment, speed and load requirements, maintenance frequency, and budget considerations.

1. Operating Environment (Dust, Moisture, Chemicals)

626Z Bearing: If your application operates in clean or low-contamination environments, the 626Z bearing may be sufficient. It provides basic protection from contaminants on one side, making it ideal for settings where exposure to dust, moisture, or chemicals is minimal.

626ZZ Bearing: For harsh environments, such as those involving dust, moisture, or chemical exposure, 626ZZ bearings are the preferred choice due to the double shields offering superior protection.

2. Speed and Load Requirements

626Z Bearing: This bearing is ideal for applications requiring low to moderate speeds and light to moderate loads, such as small motors or precision instruments. The single shield allows for efficient movement with minimal friction, making it suitable for high-speed applications.

626ZZ Bearing: If your application involves higher loads or operates in high-speed conditions, the 626ZZ bearing offers enhanced durability and protection, making it a more reliable choice for industrial and high-stress environments.

3. Maintenance Frequency

626Z Bearing: If the application is in a low-dust environment and regular maintenance is feasible, 626Z bearings will suffice. However, it may need more frequent lubrication and cleaning due to the single shield allowing more contaminants to enter.

626ZZ Bearing: For applications in challenging environments with limited access for maintenance, 626ZZ bearings provide longer intervals between servicing due to their superior contamination protection and better lubrication retention.

4. Budget Considerations

626Z Bearing: If cost is a primary factor and the operating conditions are controlled or clean, 626Z bearings offer a cost-effective solution without compromising on performance for lighter applications.

626ZZ Bearing: If your application requires higher durability and longer lifespan, and you can afford the additional expense, the 626ZZ bearing is the better investment for environments that pose greater risks of contamination.

Why Choose Hune Bearing Pulley?

When selecting bearings for your mechanical systems or pulley applications, Hune Bearing Pulley offers several advantages:

Premium Quality: We provide high-quality, precision-engineered bearings to ensure smooth performance and longer lifespans.

Wide Range of Options: Whether you need 626Z or 626ZZ bearings, or custom solutions, Hune Bearing Pulley offers a comprehensive selection to meet your specific needs.

Reliable Performance: Our products are designed to withstand harsh environments, offering superior protection against contaminants, moisture, and wear.

Competitive Pricing: Enjoy cost-effective solutions without compromising on the reliability or durability of your equipment.

For your next project, choose Hune Bearing Pulley for reliable, long-lasting bearings that meet the highest standards of quality.

FAQ

Can I Replace a 626Z with a 626ZZ Bearing?

Yes, you can replace a 626Z with a 626ZZ bearing. Both have the same size, but the 626ZZ provides better protection with shields on both sides. However, the 626ZZ may have slightly higher friction, so consider your application's need for contamination resistance versus speed.

626Z with a 626ZZ Bearing: Which One Runs Faster?

The 626Z bearing generally runs faster because it has a single shield, resulting in lower friction. The 626ZZ has double shields, which may increase friction slightly, making it slower.

Do ZZ Bearings Last Longer than Z Bearings?

Yes, 626ZZ bearings typically last longer than 626Z bearings due to the double shielding, which offers better protection against contaminants, reducing wear and tear over time.

Can ZZ Bearings Be Re-Lubricated?

Yes, 626ZZ bearings can be re-lubricated, but it may be more difficult due to the double shields. Some models have small openings for lubrication, but regular re-lubrication may require disassembly.

English

English  Español

Español  日本語

日本語