Sliding doors keep gaining fans in homes and offices alike because they make clever use of space and give rooms a fresh, open feel. The real secret to their smooth, effortless glide lies with the rollers—the small hardware pieces that carry the door along its track. But rollers aren't all built the same way. This article breaks down the important differences between standard and heavy-duty sliding door rollers so you can choose the one that actually fits your situation.

Understanding Sliding Door Rollers

To see why the choice between standard and heavy-duty matters, it helps to first understand what rollers really do. They're the parts that support the door's full weight and let it slide back and forth quietly and without catching. Rollers come in different styles, sizes, and materials, and each type is made to handle specific kinds of doors, different levels of daily use, and various surroundings. Picking the right roller means matching its strengths to the real demands of your door and how it will be used.

Standard Sliding Door Rollers

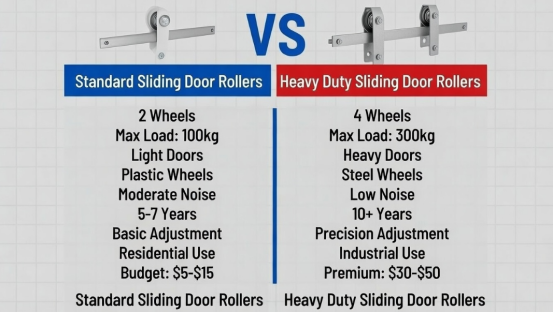

Standard sliding door rollers are built primarily for everyday, moderate use, which is why they're such a common choice for homes. They're well-suited to things like patio doors, closet sliders, and interior room dividers. Here are the key traits that define standard rollers:

- Weight Capacity They're made to carry lighter doors comfortably. These rollers handle typical residential materials without issue—hollow-core wood panels, thinner glass sections, or lightweight frames that don't place heavy demands on the hardware.

- Materials Most standard rollers use durable plastic wheels combined with lighter metal components, usually basic steel or aluminum. This keeps them affordable while still offering reliable, smooth performance under normal home conditions.

- Design and Functionality The construction is simple and practical—typically featuring one or two wheels that roll along the track. They generally include straightforward adjustment points so you can easily fine-tune alignment during setup or later if the door needs a small tweak. Installation and replacement are both quick and uncomplicated.

- Applications You'll most often find standard rollers on home patio doors, bedroom or closet sliders, and occasionally in lighter commercial settings. They perform best in spaces where doors see regular but not constant heavy use, and where traffic and wear stay relatively low.

Heavy Duty Sliding Door Rollers

Heavy-duty sliding door rollers are made for tougher jobs and heavier demands. They're the go-to choice in commercial buildings, industrial facilities, and any spot where doors see a lot of action every day. Here are the main things that set heavy-duty rollers apart:

- Weight Capacity These rollers are built strong enough to carry much heavier doors without any trouble. They handle solid wood panels, thick metal frames, large glass sections, or oversized doors that would be too much for standard hardware.

- Materials Heavy-duty rollers are typically constructed from more rugged, long-lasting materials like stainless steel, reinforced aluminum, or high-quality alloys. This gives them excellent resistance to constant wear, rust, and stress, so they keep performing reliably even in busy or rough conditions.

- Design and Functionality The build is more advanced—often featuring sealed ball bearings, precision-machined wheels, or multiple reinforced wheels that deliver smoother, quieter movement even under serious weight. Many include better adjustment systems that let you dial in alignment more precisely and keep everything running smoothly through years of frequent use.

- Applications You'll find heavy-duty rollers in places like retail shops, office entrances, hotel lobbies, restaurants, warehouses, and loading areas—anywhere doors open and close dozens or hundreds of times daily. They're also a natural fit for industrial settings such as workshops, storage buildings, and large residential projects with big or high-traffic sliding doors.

Key Differences Between Standard and Heavy Duty Rollers

- Weight Capacity

- Standard sliding door rollers are intended for doors on the lighter side and aren't equipped to deal with much extra heft, but heavy-duty rollers are deliberately constructed to take on doors that carry a substantially greater load. Choosing rollers properly matched to the door's true weight makes all the difference—fitting ones that are undersized for the task typically brings on sluggish or jerky operation, accelerated breakdown, and before long a total loss of function.

- Durability and Materials

- Heavy-duty rollers rely on much harder, more resistant materials that hold strong through endless opening and closing or rougher operating conditions, making them the practical choice for busy stores, offices, warehouses, and similar high-use spots. Ordinary standard rollers manage just fine in everyday home use but start showing serious wear much earlier if they're pushed hard day after day or exposed to less forgiving settings.

- Design Complexity

- Heavy-duty rollers tend to include more advanced features like precision ball bearings that deliver very smooth rolling and adjustable parts that let you dial in perfect alignment and smooth tracking. Standard rollers stick to a much simpler build, which keeps costs down and makes them adequate for basic needs but usually delivers less fluid motion and shorter overall lifespan in tougher applications.

- Cost Considerations

- Heavy-duty rollers naturally cost more because of the superior materials and extra engineering that go into them. The higher initial expense often makes good sense wherever the door will see heavy or frequent use, since they deliver far longer service. Standard rollers stay the budget-friendly choice when the door is only opened occasionally or handles lighter weight.

- Installation and Maintenance

- Standard rollers usually have a very basic, user-friendly design that makes replacement straightforward—something most people can handle on their own—with only light periodic attention needed afterward. Heavy-duty rollers often call for more exact positioning and fine adjustment during setup, so getting the installation right (sometimes with professional assistance) becomes more important to prevent binding, noise, or uneven wear down the line.

|

Feature |

Standard Sliding Door Rollers |

Heavy Duty Sliding Door Rollers |

|

Typical Wheel Count |

Single or Double wheel |

Triple wheel or multi-wheel reinforced design |

|

Load Capacity |

Light to medium (30–80 kg per door) |

High to very high (100–300+ kg per door) |

|

Recommended Door Type |

Interior sliding doors, lightweight patio doors, closet doors |

Large sliding glass doors, commercial storefronts, barn doors, industrial doors |

|

Material & Durability |

Standard nylon/plastic wheels, basic steel or aluminum housing |

Reinforced steel or stainless steel, heavy-duty ball bearings, industrial-grade materials |

|

Noise Level |

Moderate (can be noticeable on hard floors) |

Low to very low (designed for quiet operation even under heavy load) |

|

Lifespan / Usage Intensity |

Suitable for light to medium daily use |

Designed for high-frequency, long-term heavy use |

|

Adjustment Features |

Basic height/alignment adjustment |

Advanced multi-point adjustment, often with anti-lift and anti-jump mechanisms |

|

Typical Applications |

Residential homes, apartments, small offices |

Commercial buildings, hotels, restaurants, large residences, industrial spaces |

|

Price Range |

Lower cost |

Significantly higher cost |

Choosing the Right Roller for Your Needs

When choosing between standard and heavy-duty sliding door rollers, keep these main points in mind:

- Door Weight: Take a good look at how heavy your door actually is. Lighter doors pair well with standard rollers, but anything on the heavier side really needs the strength that only heavy-duty rollers can provide.

- How Often the Door Gets Used: Think about daily traffic. In places where the door opens and closes a lot—like busy entryways or commercial spots—heavy-duty rollers hold up far better and keep things sliding smoothly for longer.

- Operating Conditions: Factor in the surroundings. Doors facing rough weather, dust, moisture, or just constant heavy use do much better with heavy-duty rollers built to handle those tougher situations without wearing out quickly.

- Budget Reality: Figure out what you're willing to spend upfront. Heavy-duty rollers usually cost more at the start, but their extra toughness often means fewer replacements and lower hassle over the years, which can save money in the long run. Standard rollers keep the initial price lower when the door sees lighter duty.

- Ease of Installation: If you're planning to swap them yourself, standard rollers tend to be simpler and more forgiving for DIY work. Heavy-duty ones can demand more precise setup and adjustment, so in some cases bringing in a pro makes sense to get everything aligned and running right.

In the end, deciding between standard and heavy-duty sliding door rollers comes down to a few practical considerations: how heavy your door is, how frequently it will be opened and closed, the kind of conditions it will face day to day, and what you're comfortable spending. Knowing the real differences between the two types makes it much easier to pick the right hardware for your particular sliding door setup.

At Hune, we supply sliding door rollers we stand behind, and we understand why getting this choice right matters. Our products are built to deliver quiet, reliable movement and long-term performance, whether you're installing them in a home or a commercial space. We focus on quality so your doors work smoothly for years to come.

English

English  Español

Español  日本語

日本語