Replacing sliding screen door rollers can feel like a mysterious little home-repair rite—until you do it once and realize it's mostly screws, simple adjustments, and a bit of patience. The premise is straightforward: when rollers wear out, the door starts dragging, wobbling, or popping off the track, and a fresh set brings back that smooth, quiet glide. Below is a practical, step-by-step guide packed with the small "tricks" that help you avoid cracked frames, stripped screws, and a door that still won't roll right—sound good?

Tools & Materials (What You'll Actually Use)

Most screen doors are light, but the screws can be stubborn and the parts can be annoyingly non-standard. Having a few options on hand saves a hardware-store round trip.

Basic tools

- Phillips and flathead screwdrivers (a multi-bit driver is ideal)

- Tape measure (or calipers if you have them)

- Utility knife (for cutting paint or debris)

- Needle-nose pliers (for stubborn rollers/clips)

- Soft brush + shop vacuum (for track cleaning)

- Rag and mild cleaner/degreaser

Helpful extras (often worth it)

- Cordless drill/driver (use low torque to avoid stripping)

- Penetrating oil (for seized screws)

- Small file or sandpaper (for burrs on the track)

- Silicone spray (non-greasy) or a dry PTFE lubricant

- Avoid heavy grease—it collects grit and makes things worse over time.

Parts

- Replacement rollers (preferably match the old ones exactly)

- Optional: new roller screws (if the originals are rusted)

Before You Start: Diagnose and Identify the Right Roller

This is where most frustration comes from: "screen door rollers" aren't universal. The fastest path is to remove one roller first and match it.

Common symptoms of bad rollers

- Door drags even when adjusted

- Door wobbles side-to-side

- Door "clunks" or hops in certain spots

- You see flat spots or cracks on the roller wheel

- Rollers don't spin freely when touched

How to identify your roller

- Remove the door (steps below), then pull one roller assembly and note:

- Wheel diameter (often 1", 1-1/4", 1-1/2", etc.)

- Wheel material (nylon/plastic, steel, or ball-bearing nylon)

- Housing shape (rectangular, angled, stamped steel, etc.)

- Mounting method (screw through housing, rivet, clip, corner bracket)

- Offset and height (how the wheel sits relative to the frame)

Tip: Take the old roller to the hardware store. Photos help, but the part in your hand is better.

Step-by-Step: Replacing Sliding Screen Door Rollers

These steps cover the most common aluminum-framed sliding screen doors. Your door might have small variations, but the workflow stays consistent.

1) Clear the area and protect the frame

Screen door frames bend easily.

- Lay down a towel or cardboard where you'll set the door.

- Have a clear path to lift the door out without twisting it.

2) Back off the roller adjustment screws

Most screen doors have adjustment screws near the bottom corners (sometimes also at the top). These raise/lower the rollers.

- Locate the small screw on the side edge or face of the bottom rail near each corner.

- Turn counterclockwise to retract the roller upward into the frame.

Trick: If the screw just spins but nothing changes, it may be stripped or the roller housing is jammed. Don't force it yet—remove the door first, then deal with it on a bench.

3) Remove the door safely

Most sliding screen doors come out by lifting them up into the upper track and swinging the bottom out.

- Open the door halfway (gives you room to maneuver).

- Lift the door upward into the top channel.

- Pull the bottom edge toward you until it clears the lower track.

- Lower the door and carry it to your protected work surface.

If it won't lift out:

Some installations have a small anti-lift block or screw at the top. Look for:

- A screw head in the top track area

- A small bracket stopping upward movement

- Remove or loosen it, then try again.

4)

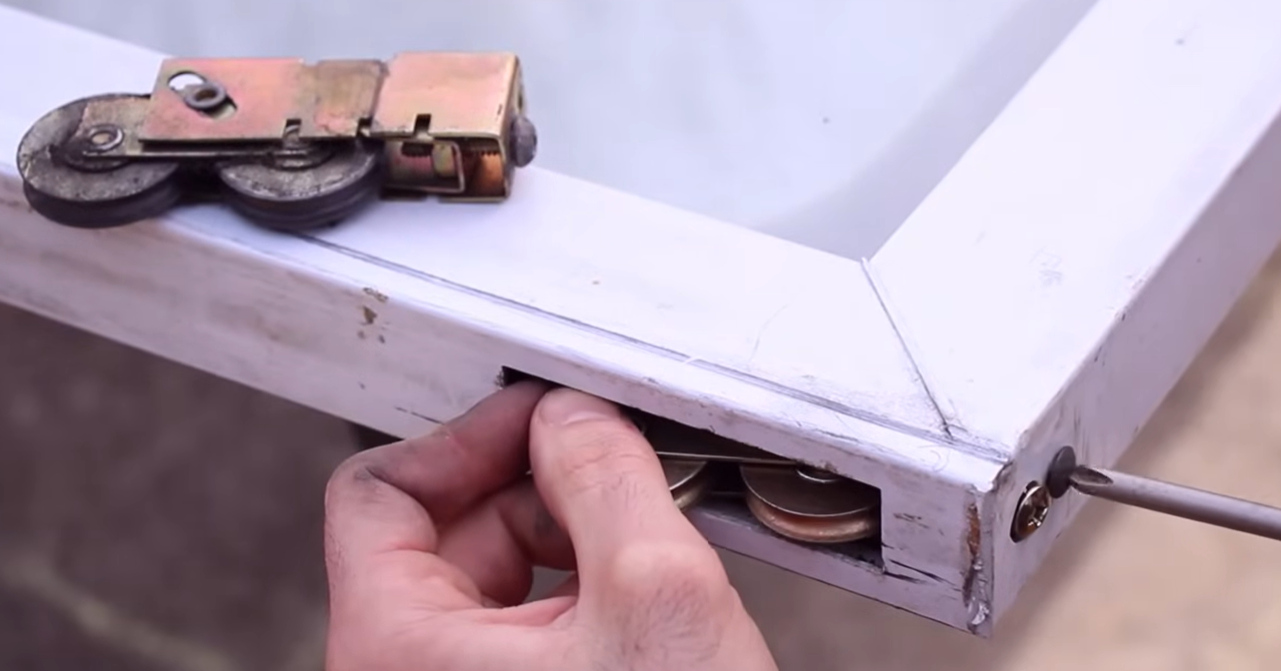

With the door on its side:

- Inspect the bottom corners. You'll usually see a roller housing held by one or two screws.

- Remove the screws and slide the housing out.

Trick for stuck housings:

A lot of roller housings are snug from oxidation. Wiggle gently with pliers and pull straight out. If the housing is trapped by a crimped corner, you may need to remove a corner screw or slightly flex the frame—gently.

5) Clean and inspect while it's apart

- This is the "make it feel new" part.

- Vacuum and brush the bottom rail channel

- Wipe the track area on the door frame

- Check for:

- Bent lower track (common if stepped on)

- Burrs or sharp dings that catch the wheel

- Loose frame corners or cracked corner keys

Trick: If the lower track has a small dent, a careful pass with a file can remove the sharp edge that makes the door “tick” every time it passes.

6) Install the new rollers

Install the replacement rollers into the same position/orientation as the originals.

- Slide the roller housing into the corner

- Install screws snug, not crushed (overtightening can distort the housing)

- Confirm the wheel spins freely

Important: Some rollers are "handed" (left/right) or have an angled housing. If the wheel seems to sit crooked, compare to the old one and flip orientation if needed.

7) Set the initial roller height (pre-adjustment)

Before reinstalling the door:

- Turn the adjustment screws so the rollers are partially extended, not fully down.

- You want enough wheel showing that the door can roll, but not so low that reinstalling is difficult.

A good starting point is: extend until you see the wheel clearly, then retract a turn or two.

8) Reinstall the door

Reverse the removal process:

- Insert the top of the door into the upper track.

- Lift upward.

- Swing the bottom onto the lower track.

- Lower it gently so it sits on the rollers.

Trick: If the screen door fights you going back in, retract the rollers slightly more, set the door in place, then extend them once it's seated.

9) Adjust for smooth glide and proper latch alignment

- This is where you make it feel "right."

- Adjust each bottom corner screw a little at a time.

- Aim for:

- Door is level (even gap along the side jamb)

- Door rolls smoothly with light fingertip pressure

- Latch lines up without lifting or slamming

- Door doesn't rub the frame or track

Adjustment method that works:

- Raise one side until rubbing stops.

- Raise the other side until the latch aligns and the door feels stable.

- Test by opening/closing fully several times.

Tips & Tricks That Save Time (and Screws)

Small details make this job either pleasant or maddening.

Use the "one-roller sample" trick

If you're unsure about replacement parts, remove one roller first and match it. Don't disassemble the whole door only to realize you bought the wrong style.

Don't lubricate dirt

Lubricating a gritty track creates a sticky grinding paste. Clean first, then apply a light silicone or dry PTFE.

If screws are stripped or seized

- Press the screwdriver firmly into the head.

- Try a slightly larger bit or a different style (Phillips vs. JIS can matter).

- Use penetrating oil and wait 10–15 minutes.

- Worst case: grip the head with locking pliers or carefully drill out the screw.

Replace both rollers

Even if only one seems bad, the other is often close behind—and mismatched wear can cause wobble.

Check the top guides (if your door has them)

Some screen doors have top rollers or plastic glides. If the door still wobbles after bottom rollers are new, inspect the top guides for cracks or missing pieces.

Common Problems After Replacement (and Quick Fixes)

If the door still isn't behaving, it's usually one of these.

Door still drags

- Rollers not extended enough (adjust down)

- Track bent inward (file burrs or gently reshape)

- Roller wheel too small/large for the track shape (wrong part)

Door jumps off the track

- Rollers extended too far (door rides too high)

- Track lip damaged or flattened

- Door frame slightly twisted (happens if it was bent during removal)

Door rolls but latch won't line up

- Door isn't plumb/level—adjust one side up/down

- Frame of the opening is out of square (common in older homes)

- In that case, set the door so it rolls well first, then adjust the latch strike if possible.

Squeaking or gritty feel

- Track still dirty

- Wrong lubricant (grease attracts grit)

- Roller bearings cheap or defective (rare, but it happens)

For Hune customers and homeowners alike, replacing sliding screen door rollers comes down to three priorities: selecting the correct replacement part, handling the frame carefully to avoid bending, and dialing in the final adjustment. Start by removing the door and taking out one roller so you can match the size and housing style precisely before purchasing parts. While the door is off, clean the track thoroughly—grit and buildup are often the real cause of rough operation. Install both new rollers for balanced support, then fine-tune the roller height until the door glides smoothly and the latch aligns properly. Use silicone or dry PTFE sparingly; cleaning typically delivers the biggest improvement.

English

English  Español

Español  日本語

日本語