Lightweight sliding doors are supposed to feel effortless—quiet glide, easy installation, low maintenance, and no drama halfway down the track. Yet many sliding setups get overbuilt with heavy-duty roller hardware designed for loads far beyond what the door actually weighs. That mismatch can create unnecessary noise, cost, and wear.

Plastic glass door rollers—typically meaning rollers with polymer wheels (often nylon, POM/acetal, or reinforced plastic compounds) paired with metal bearings and a compatible housing—hit a sweet spot for lightweight sliding systems. When chosen correctly, they deliver smooth motion, reliable performance, and a kind of "set it and forget it" simplicity that fits modern interiors and light commercial spaces.

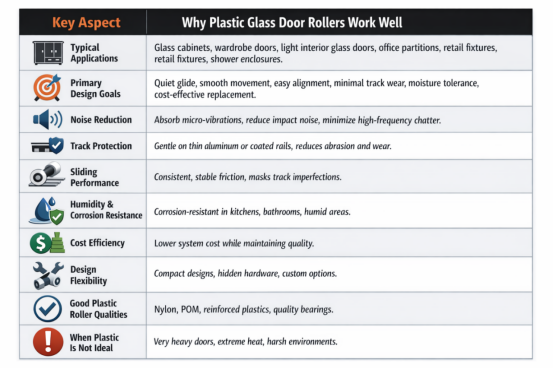

Below is a structured look at why plastic rollers often make the most sense, where they shine brightest, and what to watch for to get the performance you expect.

1) The Lightweight Sliding System Reality Check

Lightweight sliding systems include many common applications:

- Glass cabinet sliders and display cases

- Wardrobe doors (especially thinner panels)

- Light interior glass doors with top-hung or bottom-guided tracks

- Partition panels in offices or retail fixtures

- Shower or vanity enclosures (in certain designs)

In these use cases, the engineering goal is rarely "survive forklift-level abuse." It"s usually:

- Quiet, smooth glide

- Minimal track wear

- Simple adjustment and alignment

- Resistance to occasional moisture or dust

- Cost-effective replacement

Plastic rollers align with those goals because the wheel material behaves differently than metal when it meets a track: it damps vibration, reduces harsh contact noise, and can tolerate minor track imperfections without "announcing" every bump.

2) Quiet Glide: Plastic's Built-In Sound Control

If you've ever slid a door and heard a metallic rumble that makes the room feel cheaper than it looks, you've met the downside of hard-on-hard contact.

Why plastic runs quieter

Plastic wheels are slightly more compliant than steel or aluminum wheels. That tiny bit of "give" matters because it:

- Absorbs micro-vibrations caused by track seams, dust, or minor dents

- Reduces impact noise when the roller crosses small discontinuities

- Minimizes the high-frequency chatter that travels through frames and panels

For lightweight glass doors, where the panel itself can transmit vibration like a drum, this noise reduction is a practical upgrade—not just a luxury.

3) Track Friendliness: Less Wear on Lightweight Rails

Many lightweight sliding systems use tracks that are not meant to be punished—thin aluminum rails, compact channels, or coated tracks designed for indoor use.

Plastic rollers are often kinder to the track surface because they:

- Reduce metal-to-metal abrasion

- Lower the chance of gouging softer aluminum rails

- Help the track keep its shape and finish longer

That’s especially helpful in cabinet and wardrobe systems where the track may be integrated into furniture boards or slim profiles. Replacing a roller is easy; replacing a track embedded into millwork is… character-building.

4) Smooth Motion Without Over-Engineering

"Perfect" sliding isn't just low friction; it's consistent friction. Plastic rollers can provide a stable, predictable glide in lightweight setups because:

- Polymer wheels can maintain a steady contact patch on the rail

- They are less likely to transmit tiny track defects into a jerky motion

- When paired with decent bearings, they roll smoothly at low loads

For light panels, extremely hard wheels can sometimes feel "skatey" on certain tracks, especially if the system is slightly misaligned. Plastic's forgiving nature makes the whole system feel more refined—even when installation conditions aren't laboratory perfect.

5) Corrosion Resistance for Humid Indoor Environments

Not every sliding system lives in a dry living room. Bathrooms, kitchens, and coastal interiors add humidity and cleaning chemicals into the mix.

Plastic wheel material is inherently corrosion-resistant, and when the rest of the roller assembly uses stainless or appropriately coated components, you get:

- Better tolerance to humidity and condensation

- Less chance of wheel surface pitting (a common cause of noisy rolling in metal wheels)

- Longer-lasting "like new" feel in environments where metal parts can degrade

This is particularly relevant for glass doors, where users notice squeaks, roughness, and misalignment quickly—because the door "looks" premium, so the motion should match.

6) Cost Efficiency (Without Feeling Cheap)

Plastic is often cheaper than metal, but "cheap" isn't the point—value is. In lightweight systems, you usually don't need industrial wheel hardness or extreme load margins. Plastic rollers can offer:

- Lower unit cost

- Easier availability and quicker replacement

- Reduced need for heavy track materials (which also reduces system cost)

When manufacturers spec plastic rollers correctly, the user experience doesn't feel like cost-cutting; it feels like the system was designed intelligently for its real-world load.

7) Design Flexibility: More Options in Compact Spaces

Furniture and interior partitions increasingly demand slim profiles and hidden hardware. Plastic rollers help because polymer wheels can be engineered in many shapes and sizes while staying lightweight.

That enables:

- Compact roller carriages for narrow channels

- Integrated dampers or soft-close compatibility (depending on system design)

- Custom wheel geometries that better fit specialized tracks

In other words, plastic rollers are a quiet enabler of modern minimalism: less visible hardware, more effortless movement.

8) What Makes a Plastic Roller "Good"?

Not all plastic rollers are created equal. The best results come from matching wheel material, bearing quality, and track type.

Look for these features

- Quality bearing assembly (sealed bearings are a plus in dusty or humid areas)

- Wheel material suited to the environment:

- Nylon: tough, common, good wear resistance

- POM/acetal: low friction, stable, excellent for smooth glide

- Reinforced polymers: improved load handling and longevity

- Proper wheel profile for the track (V-groove, U-groove, flat, etc.)

- Accurate load rating with a safety margin

- Adjustability (height or eccentric adjustment helps compensate for installation tolerances)

Avoid these red flags

- Soft, poorly molded wheels that can flatten or crack

- Bearings that feel gritty out of the box

- Mismatched wheel profile that rides on edges instead of the intended surface

- "Universal fit" claims without specifying track compatibility

A well-made plastic roller doesn't feel like plastic in use. It feels like a door floating on rails.

9) Where Plastic Rollers Are Not the Best Choice

Perfection has a boundary. Plastic rollers may not be ideal when:

- Doors are very heavy (thick glass panels, large partitions, industrial sliders)

- The environment involves high heat, harsh solvents, or heavy contamination

- The system requires extreme impact resistance or continuous heavy cycles

- The track is badly damaged and needs the hardness of metal wheels to cope (even then, fixing the track is usually the real solution)

In short: plastic rollers excel when the system is truly lightweight and designed around smooth indoor operation—not brute-force durability.

Plastic glass door rollers from Hune are the ideal choice for lightweight sliding systems because they directly address the real-world issues users care about most:

- Remarkably quiet operation

- Exceptionally smooth and effortless gliding

- Significantly reduced wear on the track over time

- Excellent corrosion resistance, even in everyday indoor humidity

- Outstanding performance at a price that delivers premium feel without premium cost

In lightweight sliding door applications, the smartest hardware isn't always the heaviest-duty option — it's the one perfectly matched to the actual load, environment, and everyday user experience. As a specialized plastic glass door rollers factory, Hune focuses on exactly that balance. Our carefully engineered plastic rollers, when paired with a compatible track system, provide an elegantly simple solution: consistently smooth, whisper-quiet, and reliable performance day after day.

English

English  Español

Español  日本語

日本語