Noise-reducing window sliding rollers are engineered to improve the smooth operation of sliding windows while minimizing noise and mechanical wear. These rollers combine precision design with high-quality materials to deliver both comfort and long-lasting performance.

What Are Noise-Reducing Window Sliding Rollers?

Noise-reducing window sliding rollers are specialized components designed to enable smooth, quiet movement of sliding windows. Unlike traditional rollers, these are engineered to minimize friction, absorb vibrations, and reduce operational noise. Typically made from high-quality materials such as nylon, polyurethane, or rubber-coated steel, they combine durability with superior noise-dampening capabilities. Precision ball bearings or sealed roller mechanisms are often incorporated to ensure consistent alignment and smooth motion, even under heavy loads. These rollers are widely used in residential, commercial, and industrial settings where quiet, reliable window operation is essential.

Benefits of Installing Noise-Reducing Rollers

Quiet and Comfortable Operation

The primary advantage of noise-reducing rollers is their ability to deliver whisper-quiet performance. By absorbing vibrations and reducing metal-on-metal friction, these rollers eliminate squeaks, rattles, and grinding noises. This creates a more comfortable indoor environment for homes, offices, and commercial spaces, enhancing user satisfaction.

Smooth Sliding and Ease of Use

Noise-reducing rollers improve the overall functionality of sliding windows. With reduced friction, windows glide effortlessly along their tracks, making them easier to operate for people of all ages. This also reduces the risk of sudden jamming or misalignment during operation.

Extended Window Lifespan

By minimizing friction and mechanical stress, these rollers help protect window frames, tracks, and hardware from premature wear. Reduced wear translates to fewer maintenance requirements, longer-lasting windows, and lower long-term replacement costs.

Enhanced Safety and Stability

High-quality noise-reducing rollers maintain stable alignment and prevent sudden slips or jerks when sliding windows are opened or closed. This ensures safer operation, particularly in high-traffic areas or for larger window panels.

Versatility and Adaptability

Noise-reducing rollers are compatible with a wide range of window types and sizes, from residential double-hung windows to large commercial sliding panels. Their durable design ensures reliable performance under different environmental conditions and usage levels.

Energy Efficiency

By allowing windows to glide smoothly, noise-reducing rollers reduce the effort required to open and close windows. In automated or energy-conscious settings, this contributes to energy efficiency and a more convenient user experience.

|

Category |

Description |

|

What Are Noise-Reducing Window Sliding Rollers? |

Specialized rollers designed to enable smooth, quiet movement of sliding windows. Made from high-quality materials like nylon, polyurethane, or rubber-coated steel, often with precision ball bearings for smooth motion. |

|

Quiet and Comfortable Operation |

Absorb vibrations and reduce metal-on-metal friction to eliminate squeaks, rattles, and grinding noises, creating a more comfortable indoor environment. |

|

Smooth Sliding and Ease of Use |

Reduce friction, allowing windows to glide effortlessly along tracks. Prevents jamming or misalignment during operation. |

|

Extended Window Lifespan |

Minimize friction and mechanical stress, protecting window frames, tracks, and hardware from premature wear. Reduces maintenance and replacement costs. |

|

Enhanced Safety and Stability |

Maintain stable alignment, preventing slips or jerks when opening or closing windows. Ensures safer operation for larger or high-traffic windows. |

|

Versatility and Adaptability |

Compatible with various window types and sizes, from residential double-hung to large commercial sliding panels. Durable under different environmental conditions. |

|

Energy Efficiency |

Smooth gliding reduces effort required to operate windows, contributing to convenience and energy efficiency in automated or high-use settings. |

How Noise-Reducing Rollers Work?

Understanding how these rollers work helps explain why they are essential for comfort, smooth operation, and long-term durability.

1. Material Composition for Vibration Dampening

Noise-reducing rollers are typically made from high-quality materials such as nylon, polyurethane, or rubber-coated steel. These materials have natural vibration-absorbing properties, which help to reduce the noise generated when a roller moves along a track. The soft but durable surface cushions impacts between the roller and the track, preventing the squeaks, rattles, and grinding sounds commonly associated with standard rollers.

2. Precision Bearings for Smooth Motion

Most noise-reducing rollers incorporate precision ball bearings or sealed bearing mechanisms. These bearings reduce friction by allowing the roller to spin freely while supporting the load of the window, door, or machinery component. This smooth motion not only minimizes operational noise but also prevents mechanical wear on both the roller and the track.

3. Load Distribution and Alignment

Proper load distribution is crucial to the effectiveness of noise-reducing rollers. By evenly distributing weight along the track, these rollers prevent localized stress points that can cause noise, wear, or misalignment. High-quality rollers are designed to maintain consistent alignment even under heavy loads, ensuring stable and quiet operation over time.

4. Reduction of Friction and Mechanical Stress

Noise-reducing rollers work by reducing the friction between moving components. Less friction means less heat and wear, which prolongs the lifespan of the roller, the track, and the associated hardware. This reduction in mechanical stress also contributes to smoother, easier operation, enhancing user comfort.

5. Protective Coatings and Surface Design

Some noise-reducing rollers feature protective coatings or specially designed surfaces that further minimize noise and friction. For example, a rubberized or polyurethane layer can absorb small shocks, while grooves or channel designs in the roller can guide movement along the track more efficiently.

6. Long-Term Benefits

By combining vibration absorption, precise bearings, proper load distribution, and friction reduction, noise-reducing rollers extend the service life of sliding windows, doors, and machinery. They reduce maintenance requirements, prevent premature failure, and provide a consistently smooth and quiet user experience.

What Are the Differences Between Types of Noise-Reducing Rollers?

Understanding the differences between various types can help homeowners, facility managers, and engineers choose the best solution for comfort, durability, and performance.

1. Material-Based Differences

- Noise-reducing rollers are commonly made from materials like nylon, polyurethane, rubber, or coated steel.

- Nylon Rollers: Lightweight, durable, and cost-effective. They provide smooth operation with moderate noise reduction.

- Polyurethane Rollers: Known for excellent vibration absorption and long-lasting performance, polyurethane rollers are ideal for heavier sliding doors or industrial applications.

- Rubber-Coated Rollers: Offer superior noise-dampening, especially for residential settings where quiet operation is critical.

- Metal Rollers with Coatings: Steel or aluminum rollers with rubber or polymer coatings combine durability with noise reduction.

2. Bearing Design Differences

The type of bearing used in a roller significantly impacts its noise reduction and smoothness.

- Ball Bearing Rollers: Provide the smoothest operation and are ideal for heavy doors or windows. The rolling elements reduce friction and mechanical wear, enhancing longevity.

- Plain or Sleeve Bearing Rollers: Simpler and more cost-effective but may produce more noise under heavy load compared to ball bearings.

- Sealed Bearings: Protect against dust, debris, and corrosion, ensuring quieter and longer-lasting performance.

3. Load and Application Differences

Different rollers are designed to handle varying loads and applications:

- Light-Duty Rollers: Suitable for residential sliding windows or light doors. Prioritize smooth, quiet operation over heavy load capacity.

- Medium-Duty Rollers: Common in commercial windows and medium-sized sliding doors. Balance noise reduction with moderate load capacity.

- Heavy-Duty Rollers: Engineered for industrial doors, large windows, or heavy machinery. Focus on durability, alignment stability, and vibration dampening under heavy loads.

4. Track Compatibility and Design Variations

Noise-reducing rollers also differ in how they interact with tracks:

- Flat Track Rollers: Simple and versatile, suitable for general applications.

- V-Groove or U-Groove Rollers: Provide better alignment and stability, reducing lateral movement and additional noise.

- Specialty Rollers: Some are designed with self-lubricating coatings or anti-slip surfaces to improve performance on specific track types.

|

Category |

Type / Feature |

Description / Benefits |

|

Material-Based Differences |

Nylon Rollers |

Lightweight, durable, cost-effective; smooth operation with moderate noise reduction. |

|

|

Polyurethane Rollers |

Excellent vibration absorption, long-lasting; ideal for heavy doors and industrial applications. |

|

|

Rubber-Coated Rollers |

Superior noise-dampening; best for residential settings requiring quiet operation. |

|

|

Metal Rollers with Coatings |

Combines durability with noise reduction; steel or aluminum with rubber/polymer coating. |

|

Bearing Design Differences |

Ball Bearing Rollers |

Smoothest operation, reduces friction and wear; ideal for heavy doors/windows. |

|

|

Plain / Sleeve Bearing Rollers |

Simpler and cost-effective; may produce more noise under heavy load. |

|

|

Sealed Bearings |

Protect against dust, debris, and corrosion; ensures quieter, long-lasting performance. |

|

Load and Application Differences |

Light-Duty Rollers |

Suitable for residential sliding windows or light doors; prioritize quiet operation. |

|

|

Medium-Duty Rollers |

For commercial windows and medium doors; balance noise reduction with moderate load. |

|

|

Heavy-Duty Rollers |

Engineered for industrial doors, large windows, or heavy machinery; focus on durability and vibration dampening. |

|

Track Compatibility and Design Variations |

Flat Track Rollers |

Simple, versatile; suitable for general applications. |

|

|

V-Groove / U-Groove Rollers |

Provide better alignment and stability; reduce lateral movement and noise. |

|

|

Specialty Rollers |

Self-lubricating coatings or anti-slip surfaces for enhanced performance on specific tracks. |

What Factors Should You Consider When Choosing Noise-Reducing Rollers?

Selecting the right roller can significantly enhance comfort, reduce maintenance, and extend the lifespan of your systems.

1. Material Quality

The material of a roller directly affects its noise-dampening, durability, and smoothness. Common options include nylon, polyurethane, rubber-coated steel, and metal rollers with protective coatings. Nylon rollers are lightweight and cost-effective, while polyurethane and rubber-coated rollers provide superior vibration absorption and long-lasting performance. Metal rollers with coatings combine durability with noise reduction for heavy-duty applications.

2. Bearing Type

The type of bearing used in a roller influences both noise reduction and smooth motion. Ball bearings offer the smoothest performance and are ideal for heavy doors or windows, while plain or sleeve bearings are simpler and more economical but may produce more noise under load. Sealed bearings protect against dust, debris, and corrosion, ensuring long-term quiet operation.

3. Load Capacity

Consider the weight and size of the sliding door or window. Light-duty rollers are suitable for residential windows, medium-duty rollers are ideal for commercial applications, and heavy-duty rollers are designed for industrial doors or large sliding panels. Choosing a roller with appropriate load capacity ensures stable, quiet, and long-lasting operation.

4. Track Compatibility

Rollers are designed to work with specific track types. Flat track rollers are versatile and suitable for general applications, while V-groove or U-groove rollers provide better alignment, reduce lateral movement, and enhance noise reduction. Specialty rollers with anti-slip surfaces or self-lubricating coatings can improve performance on unique track designs.

5. Environmental Conditions

Consider the operating environment. Rollers used outdoors or in industrial settings may require corrosion-resistant materials or sealed bearings to withstand dust, moisture, or temperature variations. Choosing rollers suited to the environment ensures consistent performance and longevity.

6. Ease of Maintenance

Noise-reducing rollers that require minimal maintenance are ideal for residential and commercial applications. High-quality rollers with sealed bearings or self-lubricating designs reduce the need for frequent servicing, saving time and costs over the product's lifetime.

Choosing the Right Supplier or Manufacturer

Choosing the right supplier or manufacturer is crucial for several key reasons:

- Ensuring Product Quality: A reliable supplier provides high-quality products that meet standards, reducing defects and extending product lifespan.

- Lowering Maintenance Costs: Well-made products with precise manufacturing reduce the frequency of repairs, saving both time and money.

- Timely Delivery: A dependable manufacturer ensures on-time delivery, keeping projects on schedule.

- Professional Support: Reputable suppliers offer technical guidance and solutions during installation, usage, or after-sales issues.

- Minimizing Risk: Partnering with a trustworthy manufacturer reduces the risk of quality problems, delivery delays, or contractual disputes.

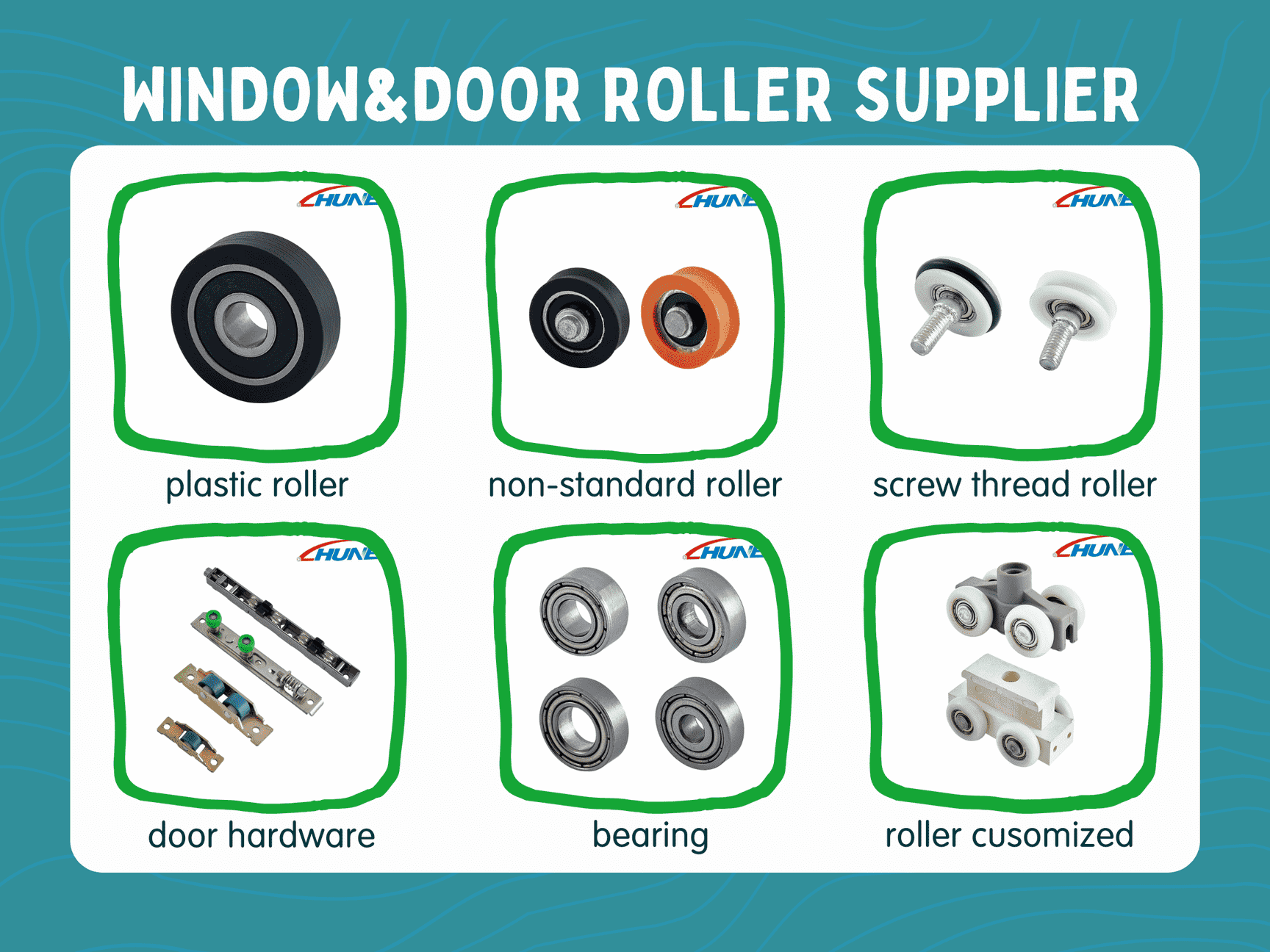

If you are looking for a reliable window sliding rollers manufacturer, I recommend the professional and trusted manufacturer – Hune. Hune specializes in producing high-quality window sliding rollers that ensure smooth, quiet operation and long-lasting performance. With precision engineering, durable materials, and advanced bearing designs, Hune's products are suitable for residential, commercial, and industrial applications.

Why Choose China Window Sliding Rollers Manufacturer – Hune

Choosing the right supplier or manufacturer for window sliding rollers is a critical decision that directly impacts product quality, durability, and long-term performance. High-quality rollers ensure smooth, quiet operation, reduce maintenance costs, and extend the lifespan of your windows or sliding doors. Partnering with a reliable manufacturer also guarantees consistent product standards, timely delivery, and excellent after-sales support.

Hune – Trusted China Window Sliding Rollers Manufacturer

Hune stands out as a leading manufacturer of high-quality window sliding rollers in China. With years of experience in producing precision-engineered rollers, Hune focuses on combining durability, smooth operation, and noise reduction. Their products are made from premium materials and feature advanced bearing designs to ensure optimal performance for residential, commercial, and industrial applications.

By choosing Hune, you gain access to:

- Superior Quality: Rollers crafted with precision and high-grade materials for long-lasting performance.

- Smooth and Quiet Operation: Noise-reducing designs for enhanced comfort in any environment.

- Customized Solutions: Options to meet different load requirements, track types, and specific applications.

- Reliable Service: Professional support from production to delivery, ensuring peace of mind.

Selecting Hune as your window sliding rollers supplier means investing in reliability, performance, and efficiency. Their commitment to quality and innovation makes them a trusted partner for clients worldwide looking to enhance the durability and comfort of sliding windows and doors.

English

English  Español

Español  日本語

日本語