Over the past few years, we have diligently pursued higher standards to enhance our product quality, aiming to deliver increased convenience and a better user experience.

-

0㎡Plant Area

0㎡Plant Area -

0+Staff

0+Staff -

0Established in

0Established in -

0+Exporting Countries

0+Exporting Countries

Everything You Need to Know About Aluminum Roller Sliding Door and Window Sash Pulley Wheels

Think about the doors and windows you interact with every day. Imagine if every open and close felt completely effortless—no sticking, no scraping, no frustrating noises. That simple improvement doesn't just enhance comfort; it actively safeguards your home, furniture, and frames over the long term.

Worn or low-quality rollers and pulleys are the silent culprits behind most sliding issues. They generate excess friction, require more force to operate, and gradually damage tracks, frames, and seals. The result? Rattling windows that allow drafts, cabinet doors that no longer align properly, or heavy sliding panels that demand extra effort to move.

Select the right pulley wheel, and the experience transforms completely.

Benefits of Smooth, Precise Sliding

- Complete Sealing

- Doors and windows close fully, blocking dust, drafts, insects, and moisture effectively.

- Reduced Wear

- Lower stress on tracks and frames keeps everything aligned and structurally sound for decades.

- Quiet Operation

- Silent performance that never disturbs family, guests, or customers—even during quiet hours.

- Effortless Use

- Minimal force needed, making it ideal for children, elderly users, or high-traffic commercial areas.

Furniture Protection Wardrobes, kitchen cabinets, and display units glide perfectly year after year—preventing sagging, misalignment, and surface damage to both the furniture and stored contents.

High-quality sliding hardware delivers stable performance, low friction, quiet running, and minimal maintenance—perfect for residential and commercial applications alike.

Our Aluminum Roller Pulley Wheel

Our Aluminum Roller Pulley Wheel is a premium hardware component engineered for seamless sliding in doors, windows, and panel furniture systems.

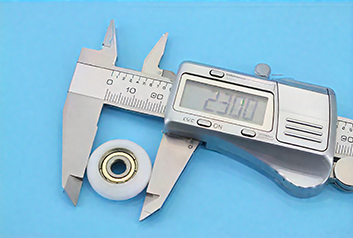

Unlike multi-roller designs, it features a single, strongly built roller combined with precision advanced bearings. This streamlined setup efficiently handles both guidance and load support along the track—providing excellent stability with fewer components.

Built to Endure – Durable Construction

We manufacture these wheels from resilient alloy metals, brass, or specially chosen corrosion-resistant materials to ensure long-lasting strength and resistance to wear. This robust design maintains steady, whisper-quiet performance through frequent use, making it suitable for homes, offices, commercial spaces, and industrial environments.

Advantages of Aluminum Roller Sliding Door & Window Sash Pulley Wheel

|

Feature |

Description |

|

Smooth & Quiet |

Low-friction bearings ensure effortless, silent sliding. |

|

Stable & Safe |

Balanced design keeps motion controlled and reliable. |

|

Low Maintenance |

Durable materials resist rust and wear. |

|

Sleek Design |

Compact and modern, fits seamlessly with any system. |

|

Long-Lasting |

Durable and efficient for sustainable use. |

Types of Aluminum Roller Pulley Wheels

Aluminum roller pulley wheels form the backbone of reliable door, window, and furniture hardware systems. They deliver an outstanding combination of low weight and high strength, with smooth, effortless rotation and superior protection against wear and corrosion—ensuring consistent performance over years of service.

We develop our aluminum rollers and pulleys to suit every type of installation, from delicate household furniture to robust industrial sliding doors. Each design is purpose-built around real-world load conditions, required movement accuracy, and available space, resulting in components that integrate perfectly and perform flawlessly.

Our Product Families

- Sliding Door Rollers – Built for Constant Heavy Use These substantial, large-diameter rollers are made to support large patio doors, interior partitions, and high-traffic commercial openings without issue. Turned from solid aluminum bar and featuring a gently crowned running surface for perfect rail alignment, they are equipped with precision sealed stainless steel bearings that provide silent operation and full resistance to water and dust in any climate.

- Window Sash Rollers – Ensuring Smooth and Level Vertical Travel Compact in profile yet exceptionally strong, these rollers fit inside tight window frames and hold sashes steady and level season after season. A convenient side-mounted adjustment screw allows millimetre-perfect height setting during installation, locking securely once aligned. Many versions include a built-in anti-lift device for increased security.

- Wardrobe and Cabinet Rollers – Quiet and Invisible Performance Our most discreet rollers are sized to hide completely within slim doors and panels of closets and cabinets. Manufactured from premium aluminum and stainless steel, they run with almost no noise at all. On selected models, a soft polymer tire is applied over the aluminum wheel for completely silent movement and to prevent any marking on sensitive flooring.

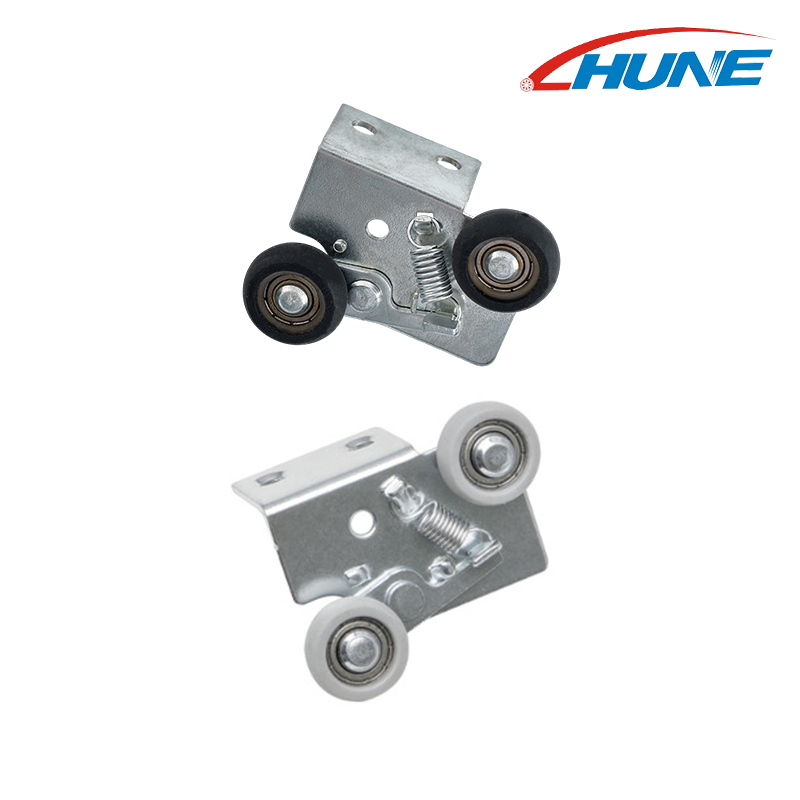

- Heavy-Duty and Specialised Rollers – Ready for the Toughest Tasks For demanding applications including industrial gates, telescopic walls, retail displays, or exposed coastal locations, we produce reinforced rollers with heavy-duty mounting plates, double bearings, spring-loaded compensation, or eccentric adjustment features. Whatever the challenge, we supply a roller engineered specifically for it.

Every roller we offer is designed, machined, finished, and tested entirely in our own workshop. These are our own original products, proven first on the systems we install ourselves—so you can be confident they deliver exceptional durability and precision from day one.

Types of Aluminum Roller Pulley Wheels

|

Application |

Description |

|

Sliding Doors |

Aluminum rollers ensure smooth, quiet, and stable operation, even for heavy panels. |

|

Windows |

Maintain alignment and effortless gliding; resistant to rust and weathering. |

|

Furniture |

Compact, durable, and quiet; sleek finish fits modern interiors. |

|

Custom/Heavy-Duty |

Reinforced, precise, and reliable for industrial or specialized use. |

Installation and Maintenance Guide for Aluminum Roller Pulley Wheels

Based on extensive practical experience from our projects, we've established a core truth: the highest-quality roller can only shine with correct installation. This is why we provide direct, reliable guidance drawn straight from the proven methods our skilled installation crews use on site every day.

Tools Needed

- Phillips and flat-head screwdrivers

- Adjustable wrench or matching Allen keys (specific to your model)

- Spirit level

- Measuring tape

- Clean cloth and mild cleaner

- Soft-faced mallet (avoid any direct contact with the roller)

Keep the work area spotless. Even minor dust or debris trapped in a sealed bearing can impact long-term reliability.

Installation for Sliding Doors

- Clean the track completely Vacuum all debris, wipe with a damp cloth, and dry thoroughly. This prevents abrasive particles from causing wear right from the start.

- Attach rollers to the door Place rollers in the designated holes or slots. Tighten mounting screws finger-tight at first, then add just half a turn—do not overtighten.

- Hang the door Best done with two people: tilt the door, set the rollers into the track, and lower it gently. Rollers should rest evenly with no lateral pressure.

- Check and adjust alignment Close the door fully and ensure gaps are consistent top and bottom. Turn adjustment screws (clockwise to raise, anti-clockwise to lower) until the door is perfectly parallel to the frame.

- Test movement Open and close the door slowly several times. It should move easily with one finger and stay completely silent. Any sound means further adjustment is required.

- Secure the settings When everything is perfect, lightly tighten the locking screws.

Installation for Sliding Windows

- Clean upper and lower channels thoroughly—dust often builds up unnoticed.

- Mount rollers on the bottom rail of the lower sash.

- Place the sash in the frame and run it through its full travel.

- Adjust height for level seating and uniform, light contact with weather-stripping all around—no gaps or binding.

- Cycle the window 10–12 times, listening for smooth and quiet operation.

Installation for Wardrobes and Cabinet Doors

- Dry-fit doors and test their movement on the track before final fixing.

- Use only our recommended track profile—mismatched tracks commonly cause noise and early wear.

- If the floor is uneven, set the front roller slightly higher than the rear for natural self-closing.

- Install the supplied plastic end caps to keep dust out of the bearings.

Common Mistakes to Avoid

- Over-tightening roller housings until they distort: tighten until snug, then only a little more.

- Not cleaning the track again after drilling, cutting, or painting: a second clean is often essential.

- Fitting the door before the track is confirmed level: rollers cannot correct an unlevel track.

- Skipping the final test runs: several slow cycles reveal problems that measurements alone might not show.

By following these exact procedures—refined through our own daily work—your aluminum rollers will provide the smooth, silent, and enduring performance we design and build them to achieve.

Maintaining Your Aluminum Roller Pulley Wheels for Enduring Smooth Operation

We produce our rollers with a focus on long-term reliability, but as precision moving parts, they achieve their full potential with minimal periodic care. The required maintenance is effortless and usually takes only a few minutes, once or twice each year.

Regular Cleaning – The Primary Step for Sustained Performance

Every few months, open the door or window completely and wipe the track using a clean, dry cloth. Follow by cleaning the visible section of the roller. This routine measure prevents virtually all common concerns.

If dust or residue is evident in the track, vacuum it thoroughly first, then wipe with a cloth slightly moistened with water, and dry immediately. Avoid abrasive substances or pressure washing, which may introduce particles into the sealed bearings.

Annually, apply one drop of light machine oil or a light application of silicone lubricant to the axle zone (do not use grease, as it accumulates dirt). Manually spin the wheel several times to distribute evenly, then wipe away any remaining excess.

Identifying Early Signs of Wear

Monitor closely during normal use:

- Fully smooth and silent action signifies perfect condition.

- Light grinding or clicking generally requires cleaning and lubrication.

- Severe crunching or abrupt stiffness points to the need for bearing inspection or replacement.

Visually assess the panel:

- Developing uneven gaps or one-side sagging often indicates track debris or a small height adjustment.

Practical Adjustments We Apply On-Site

If the panel becomes harder to operate:

- Open it midway and support the weight (preferably with help).

- Loosen each roller's locking screw by about half a turn.

- Adjust the height screw in quarter-turn steps until level is achieved.

- Retighten the locking screw and test for ease of movement.

- Never force a jammed panel—lift it carefully off the track prior to sliding.

Typical Issues and Trusted Resolutions

- Noise appearing suddenly: Most often dust-related. Thorough track cleaning and a drop of oil will correct it.

- Panel binds or stops partway: Usually a small trapped object or paint—remove it to regain full smoothness.

- Panel drifts open or closed: Typically from slight floor changes. Position the front roller marginally higher (or lower) than the rear.

- One side sits lower: Increase the height of the roller on the low side until gaps match top and bottom.

By performing these uncomplicated, regular tasks, the rollers we manufacture will preserve their effortless, quiet performance over many years—regularly exceeding the service life of other installation components. This is the superior durability and dependability we integrate into every roller we create.

Selecting the Ideal Aluminum Roller Pulley Wheels – Our Field-Tested Guidelines from Actual Installations

From hands-on experience with thousands of sliding systems we've installed ourselves, one principle stands out: choosing the wrong roller can ruin the entire setup, no matter how carefully it's fitted. Doors may begin to sag, windows can stick, or wardrobes might develop annoying rattles in just a year. These are the precise guidelines we follow every time we select rollers for our projects.

1. Align the Roller with Its Intended Use

- Sliding Doors (patio doors, interior partitions, commercial entrances) We consistently choose our largest-diameter, heavy-duty rollers for these applications. The panels are often heavy and used frequently, demanding rollers that can reliably support substantial weight without flattening or becoming unstable.

- Sliding Windows (horizontal or vertical sashes) Limited space in the frame requires our slim-profile rollers with fine height adjustment capabilities. The focus is on achieving light, effortless movement and preserving perfect alignment over years of regular operation.

- Wardrobes, Cabinets, and Lightweight Interior Doors Compact size and complete silence are paramount here. We select our smallest rollers that still feature high-quality stainless steel bearings—ensuring no noise during everyday use.

- Each category has dedicated roller designs with specific groove shapes and bearing dimensions—combining them across applications is not advised.

2. Determine the Load Precisely – Avoid Estimation

- Weigh everything accurately: glass panels, frames, hardware, handles, and locks. Then specify rollers with a rated capacity comfortably exceeding the total. We always include an extra safety buffer for rough handling or slamming. Operating a roller at approximately 70% of its maximum load can extend its service life three to four times compared to running it at full capacity.

3. Factor in the Operating Environment

- Coastal homes, bathrooms, or exterior installations Only our fully sealed, hard-anodized rollers with stainless steel bearings are used in these conditions. Lesser options corrode and bind rapidly in salty or moist air.

- Areas with underfloor heating, intense sunlight, or significant temperature swings Aluminum's low thermal expansion ensures consistent alignment year-round, far superior to plastic alternatives.

- Quiet spaces such as bedrooms, offices, or hotels We specify our ultra-quiet models, frequently with polymer-coated wheels, for truly inaudible operation.

4. Prioritize Long-Term Value Over Initial Cost

- Budget alternatives are readily available—and we've replaced countless failed units over the years. Low-cost rollers typically fail within two to three years, whereas ours continue to perform perfectly after ten or fifteen years on the same systems. When replacement labor and downtime (particularly for heavy doors) are considered, premium rollers are by far the most economical choice.

- We refuse to cut corners on roller quality because the entire installation—track, frame, and glazing—depends on those critical contact points performing flawlessly, day after day, for decades.

- Select the right roller once, and it will deliver reliable service without further concern. This is the exacting standard we maintain in our own installations and the recommendation we extend to every customer and professional we work with.

Who Provides Reliable Aluminum Roller Pulley Wheels?

Hune Pulley Wheels – Your Partner in Sliding Door and Window Hardware

Hune has earned its place as a respected manufacturer of high-performance sliding door and window hardware, with our core strength lying in premium aluminum roller pulley wheels. We focus on delivering precision-built components that combine exceptional reliability with impressive long-term performance for both residential and commercial projects.

Every pulley wheel we produce is engineered to provide exceptionally smooth, silent, and consistent operation, giving end-users a superior sliding experience that requires almost no ongoing attention.

Hune's Real-World Manufacturing Experience and Strict Quality Discipline

Hune brings together years of hands-on production expertise and uncompromising quality standards. Each aluminum roller pulley wheel is made to exacting tolerances—from material selection and machining through to final assembly and surface finishing.

What sets our process apart:

- In-Depth Quality Control: Multiple checks at every production stage to ensure lasting strength and flawless function.

- Precision Craftsmanship: Bearings and housings manufactured for effortless, dependable movement over years of service.

- Highest-Grade Materials: Only superior aluminum alloys chosen for outstanding corrosion resistance, structural integrity, and proven longevity.

This rigorous approach guarantees that Hune pulley wheels perform reliably across every type of sliding application.

Why Homeowners and Commercial Clients Choose Hune

From private residences to large-scale commercial installations, Hune aluminum roller pulley wheels are trusted for good reason.

- Proven Smooth Operation: Quiet and effortless performance, even with heavy daily use.

- Built to Last: Engineered to resist wear, environmental challenges, and constant operation.

- Perfect Fit for Any Project: Ideal for doors, windows, wardrobe systems, furniture, and industrial sliding panels.

Our reputation is built on delivering technical excellence that works perfectly in the real world—consistently meeting the standards of professional installers and end-users alike.

FAQ: Aluminum Roller Sliding Door and Window Sash Pulley Wheels

1. What are the advantages of using a aluminum roller pulley wheel over other types?

- Aluminum roller pulley wheels provide smooth, quiet operation with minimal friction. They are compact, durable, and easier to install, making them ideal for sliding doors, windows, and furniture systems where reliable movement is essential.

2. Can aluminum roller pulley wheels be used on furniture systems like cabinets and wardrobes?

- Yes. Aluminum roller pulley wheels are versatile and can be used for cabinets, wardrobes, sliding panels, and other furniture, providing easy mobility and reducing noise during operation.

3. How do I know if my sliding door or window needs a new pulley wheel?

- Signs include difficulty in sliding, unusual noise, jerky movement, or visible wear on the pulley. Replacing worn pulley wheels restores smooth operation and prevents further damage.

4. Are aluminum roller pulley wheels suitable for commercial and industrial applications?

- Yes. High-quality aluminum roller pulley wheels can handle heavier loads and frequent use, making them suitable for offices, shops, warehouses, and other commercial or industrial environments.

5. Do aluminum roller pulley wheels reduce noise during operation?

- Absolutely. Pulley wheels with precision bearings and smooth rollers minimize friction and vibration, ensuring quiet operation for doors, windows, and furniture.

6. How do I maintain my aluminum roller sliding door or window pulley wheels?

- Regular maintenance includes cleaning dust and debris, lubricating the bearings, and checking for wear. Proper maintenance prolongs lifespan and ensures consistent smooth performance.

7. What are the common problems caused by low-quality pulley wheels?

- Low-quality wheels can cause squeaking, sticking, uneven sliding, and faster wear. They may also damage tracks or frames, reducing the overall lifespan of doors or windows.

8. Can aluminum roller pulley wheels be customized for specific door or window sizes?

- Yes. Many manufacturers, including Hune, offer customization options for diameter, bearing type, and load capacity to fit unique sliding door or window systems.

9. Are Hune aluminum roller pulley wheels different from other manufacturers?

- Hune pulley wheels are precision-engineered for smooth, reliable performance, using high-quality materials and durable bearings. Compared to generic products, Hune wheels offer longer lifespan and consistent operation.

10. Can these pulley wheels withstand moisture and corrosion in humid environments?

- Yes. Pulley wheels made from galvanized iron, copper, or brass with anti-corrosion finishes are resistant to rust and humidity, making them suitable for kitchens, bathrooms, and other damp environments.

11. What are the typical finishes or coatings available for these pulley wheels?

- Common finishes include galvanized, brass, nickel-plated, and powder-coated options, offering corrosion resistance and aesthetic compatibility with doors, windows, or furniture.

12. Is it possible to replace only the roller or bearing without changing the entire pulley?

- In many designs, including Hune pulley wheels, the roller and bearing can be replaced individually, allowing cost-effective maintenance without the need to replace the entire pulley assembly.

13. Where can I buy reliable aluminum roller sliding door and window sash pulley wheels?

- Reliable pulley wheels are available from trusted manufacturers like Hune Pulley Wheel, which offers high-quality products, customization options, and professional support for residential, commercial, and industrial applications.

English

English  Español

Español  日本語

日本語