Over the past few years, we have diligently pursued higher standards to enhance our product quality, aiming to deliver increased convenience and a better user experience.

-

0㎡Plant Area

0㎡Plant Area -

0+Staff

0+Staff -

0Established in

0Established in -

0+Exporting Countries

0+Exporting Countries

Is Your Shower Door System Performing at Its Best, or Could It Be Upgraded for Smoother, More Reliable Functionality?

When it comes to the performance of your bathroom's shower system, the smoothness and durability of the door's movement are essential. Curved shower doors, in particular, require specialized components like plastic roller wheels to ensure they glide effortlessly without compromising strength. While often overlooked, these small yet mighty parts are key to achieving a seamless and quiet shower experience.

But are your shower door rollers working as efficiently as they could be to enhance the overall experience of your bathroom?

Understanding the Role of Plastic Roller Wheels in Shower Door Systems

What Are Plastic Roller Wheels and Their Purpose in Shower Doors?

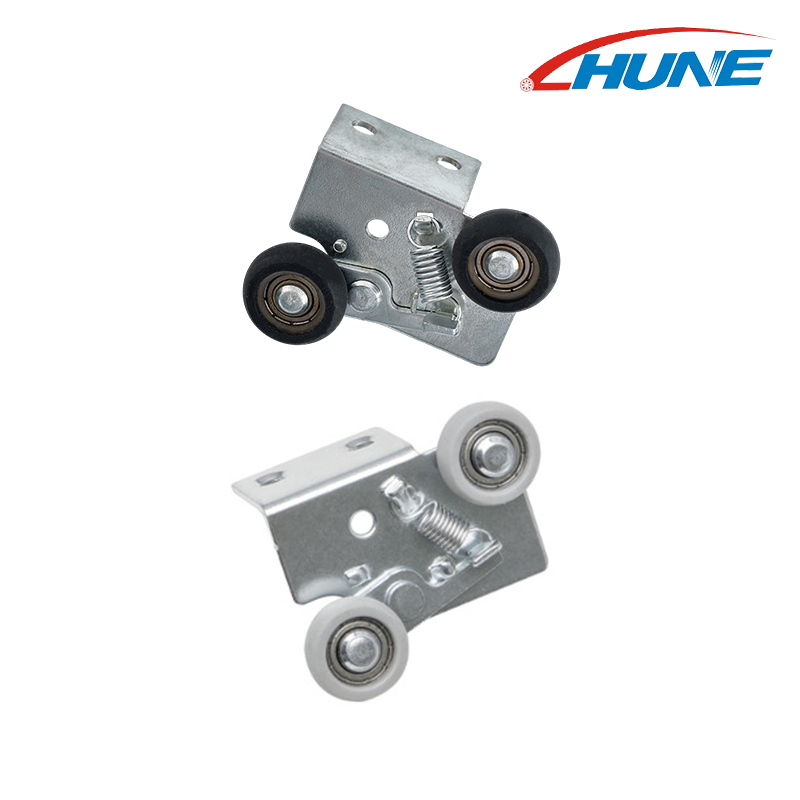

Plastic roller wheels are the small, yet powerful components that enable shower doors to glide open and closed with minimal effort. These wheels are typically mounted on the top and/or bottom of the door, fitting into the track system that guides the door's movement. For both curved and straight shower doors, the roller wheels are responsible for:

- Smooth Movement: They reduce friction between the door and the track, allowing the door to slide effortlessly.

- Even Distribution of Weight: Plastic roller wheels ensure that the weight of the door is evenly distributed, reducing wear and tear on the door and track system.

- Quiet Operation: High-quality roller wheels eliminate the noise caused by metal-on-metal contact, providing a peaceful shower experience.

In curved shower doors, where the track bends to follow the enclosure's shape, the roller wheels are designed to accommodate these unique angles and ensure the door moves seamlessly along the curve. In straight shower doors, roller wheels are still crucial for maintaining smooth sliding along the linear track, though the design of the track is less complex.

How Roller Wheels Contribute to Smooth and Reliable Movement

The mechanics behind roller wheels are relatively simple but effective. A typical roller wheel features:

- Bearings or a rotating axle: This allows the wheel to spin freely as the door moves, minimizing friction between the door and track.

- Polymer or plastic wheels: These materials are lightweight yet durable, ensuring that the door slides smoothly without excessive force. Plastic wheels are also less prone to wear over time compared to metal counterparts.

- Grooved or flanged design: Many plastic roller wheels are designed with grooves or flanges that help keep the wheel in place within the track. This prevents the door from becoming misaligned or coming off track.

The smoothness of the roller wheels' rotation directly influences the door's overall performance. High-quality roller wheels, paired with proper track alignment, ensure that your shower door glides without friction or resistance, making daily use effortless.

Signs That Your Bathroom/Shower Door System Needs an Upgrade

When it functions properly, it provides a smooth and reliable experience, allowing for easy access and a quiet, hassle-free operation. However, over time, wear and tear on components like roller wheels can lead to performance degradation. Recognizing the signs that your system needs an upgrade will help prevent further damage and ensure long-term reliability.

Identifying Wear and Tear in Existing Roller Wheels

Roller wheels are a critical component of your shower door system. They are responsible for ensuring smooth movement along the track, allowing the door to slide with ease. Over time, repeated use, moisture exposure, and the pressure of daily operation can cause wear and tear on the roller wheels. Here are the common signs of deterioration:

Visible Damage

Cracks or Chips: Check the surface of the roller wheels for cracks or chips. Any visible damage can cause the wheels to malfunction or prevent them from gliding smoothly along the track.

Worn-Out Surfaces: Over time, the plastic surface of the roller wheel may become worn down, especially in high-traffic bathrooms. This can lead to poor performance and a rougher movement.

Deformed or Misshapen Wheels

If the wheels are no longer perfectly round or have become misshapen, they may no longer fit properly in the track, causing the door to skip, wobble, or drag during operation.

Rust or Corrosion

Even though plastic roller wheels are resistant to rust, the metal components (if any) of the wheel system can corrode over time, especially if exposed to excessive moisture. This can affect the overall functionality and lifespan of the wheels.

Performance Degradation Indicators: Tracking Uneven Door Movement, Instability, and Sticking Issues

As roller wheels begin to wear out, you may notice several performance issues that indicate it's time for an upgrade. These signs are often the result of the roller wheels no longer functioning at their optimal level:

Uneven Door Movement

- One-Sided Sliding: If your shower door is moving unevenly, with one side lagging behind the other, it could be due to a damaged or misaligned roller wheel. This can cause the door to shift or become stuck when opening and closing.

- Unbalanced Door Action: A door that swings too far in one direction or has trouble staying in place may indicate that one or more wheels are not securely fitted into the track.

Instability or Wobbling

- If your shower door feels unstable, wobbly, or prone to falling off the track, this is often caused by degraded roller wheels that can no longer properly support the weight of the door. Over time, this can lead to more significant damage to both the door and the track system.

Sticking or Jamming Issues

- If the door is difficult to move or gets stuck frequently, this could be due to the increased friction caused by worn-out roller wheels. The friction generated when the wheels no longer glide smoothly along the track can cause the door to stick, making it frustrating to open and close.

Excessive Noise

- Squeaking or Grinding Noises: When roller wheels are in good condition, they should operate quietly. If you notice loud, persistent squeaks or grinding sounds, it's often an indication that the wheels are either worn down or dirty. This friction not only disrupts the peaceful atmosphere of your bathroom but also contributes to more wear over time.

How Upgrades Can Address These Problems and Extend the Lifespan of Your Shower System

Upgrading your roller wheels to high-quality, durable options is one of the best ways to restore your shower door system's functionality and prevent future issues. Here's how an upgrade can address common performance problems and extend the life of your system:

Improved Glide and Smoother Operation

New, high-quality plastic roller wheels (such as those made from nylon, polycarbonate, or UHMW) provide a much smoother glide, reducing friction and improving the overall performance of the door system. This ensures easy, quiet movement with minimal resistance, preventing sticking or jamming.

Enhanced Stability and Support

Upgraded roller wheels, particularly those with load-bearing bearings or reinforced designs, offer improved weight distribution, preventing wobbling and instability. This helps maintain a stable, secure system for the life of the door.

Durability in High-Humidity Environments

High-quality roller wheels are designed to resist corrosion and moisture damage. By upgrading to moisture-resistant materials, you can ensure your shower door system continues to perform reliably, even in the most humid bathroom environments.

Noise Reduction

A smooth and frictionless system reduces unwanted noise. Upgrading to low-friction plastic wheels eliminates squeaking, grinding, and other irritating sounds, allowing for a peaceful shower experience.

Easy Maintenance and Longer Lifespan

Newer roller wheels often come with self-lubricating bearings or more durable materials, which means they require less maintenance and can last significantly longer than older, degraded wheels. This reduces the frequency of repairs and replacements, saving both time and money in the long run.

Cost-Effectiveness

While upgrading roller wheels may require an initial investment, it ultimately saves money on repairs, maintenance, and the potential replacement of the entire shower door system. In the long term, an upgrade is a smart investment that improves both performance and aesthetic appeal.

Selecting the Right Plastic Roller Wheels for Your Shower Door

Roller wheels are the unsung heroes of any shower door system, as they are responsible for the ease, stability, and longevity of the door's movement. Whether you have a curved or straight shower door, choosing the correct roller wheels is crucial for maintaining performance and minimizing wear and tear.

Key Factors to Consider When Selecting Roller Wheels

Selecting the right roller wheels involves several important considerations to ensure you get the best performance and durability from your shower door system. Here are the main factors you should keep in mind:

Material

The material of the roller wheel is critical to its performance, durability, and maintenance requirements. Different materials offer different benefits, so it's essential to choose one that matches the needs of your bathroom environment. Here are the most common materials used in plastic roller wheels:

- Nylon: Known for its low friction and durability, nylon is one of the most popular materials for roller wheels. It is abrasion-resistant, lightweight, and ideal for regular residential use. Nylon wheels provide a smooth, quiet glide and are resistant to moisture, making them a solid choice for shower doors.

- Polycarbonate: A more rigid material, polycarbonate is ideal for environments that require extra strength and impact resistance. It is more durable than nylon and suitable for commercial or high-traffic bathrooms.

- UHMW (Ultra High Molecular Weight Polyethylene): UHMW offers exceptional wear resistance, making it perfect for curved shower doors that experience more friction and stress. It is a high-performance material known for its longevity.

- PVC (Polyvinyl Chloride): PVC is cost-effective and suitable for lighter shower doors. While not as durable as nylon or polycarbonate, it's ideal for budget-friendly projects and smaller, residential shower doors.

Each material has its pros and cons, so choosing the right one depends on your shower door's specific needs and the conditions of your bathroom.

Weight Capacity

The weight capacity of the roller wheels determines how well they can handle the load of the shower door. This is especially important for heavy glass shower doors. If the roller wheels are not rated for the correct weight, they can wear out quickly, leading to performance issues like wobbling or difficulty sliding. Always check the manufacturer's specifications to ensure the roller wheels can support the weight of your door, especially if it's large or made from heavy materials like tempered glass.

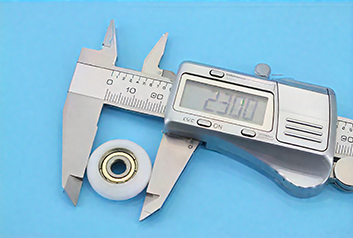

Size and Diameter

The size and diameter of the roller wheels affect how they fit into the track and their overall performance. Larger wheels tend to glide more smoothly and distribute the door's weight more evenly, while smaller wheels are better for lighter doors. The diameter of the wheel should also match the track size; otherwise, the door may not slide properly, leading to instability or misalignment.

Track Compatibility

The track system in your shower door setup is another crucial consideration. Make sure the roller wheels you choose are compatible with your specific track design. Some roller wheels are designed for standard tracks, while others are made for curved or customized tracks. For example, curved shower doors require specialized wheels that can navigate the bends of the track, while straight door systems require wheels optimized for linear tracks. The shape, depth, and width of the track can influence the type of roller wheel needed for optimal performance.

Comparing Different Types of Roller Wheels for Curved vs. Straight Shower Doors

The type of shower door system you have—curved or straight—plays a significant role in determining the type of roller wheels you need. Here's a comparison of the two systems and the roller wheels that work best for each:

Curved Shower Doors

- Roller Wheels Design: Curved shower doors require specialized roller wheels designed to handle the unique demands of curved tracks. These wheels must navigate tight curves without losing stability or alignment. Polyurethane and UHMW wheels are ideal for curved systems because of their high durability and low friction.

- Track Requirements: Curved tracks have a circular or semi-circular shape, so the roller wheels must have a profile that accommodates the curve while providing smooth, uninterrupted motion. It's important to choose wheels that fit snugly into the track to avoid wobbling or skipping.

- Wheel Size: Larger roller wheels are often preferred for curved systems because they help distribute the weight evenly across the curve, reducing strain on the track and preventing premature wear.

Straight Shower Doors

- Roller Wheels Design: Straight shower doors are more straightforward when it comes to roller wheel selection. Standard nylon or PVC roller wheels can be used effectively for linear tracks. These materials provide a smooth and quiet glide for everyday use.

- Track Requirements: Straight tracks are simple and usually require wheels that move along the track's linear path. The wheel's size and diameter should match the width of the track to ensure proper alignment and smooth operation.

- Wheel Size: Depending on the weight of the door, straight track systems may require either small or large roller wheels. Heavy glass doors will require larger wheels to support the load and prevent excessive wear on the track.

How to Match the Correct Roller Wheels with the Overall Design and Structure of Your Shower Door

To ensure optimal performance, it's essential to match the roller wheels to your shower door's design and overall structure. Here are a few tips to help you make the right choice:

Consider the Door Material

If you have a heavy glass door, ensure that the roller wheels you select are capable of handling the additional weight. For lighter doors, smaller or more basic roller wheels will suffice. Heavier systems require reinforced roller wheels made from high-performance materials like polycarbonate or Delrin.

Assess the Shower Door Style

For sliding shower doors, choose roller wheels designed for easy side-to-side movement. If you have a bi-fold or pivot door, ensure the wheels are designed for the specific hinge mechanism and can support multiple directional movements.

Check the Track Design

As mentioned earlier, ensure the wheel size and design are compatible with your track system. If you're upgrading or replacing old wheels, make sure the new wheels fit snugly into the existing tracks for seamless movement. For curved tracks, ensure the wheels are designed to work with curves without compromising performance.

Focus on Maintenance Requirements

If you want to reduce maintenance and extend the lifespan of your shower door system, choose roller wheels with self-lubricating bearings or moisture-resistant coatings. This will help prevent buildup of debris and ensure smoother operation over time.

Step-by-Step Guide to Upgrading Your Shower Door Roller Wheels

Over time, the roller wheels wear down due to constant friction, moisture, and regular use. Replacing them with high-quality plastic roller wheels can restore the functionality of your system.

Instructions for Replacing or Upgrading the Plastic Roller Wheels in Your Shower Door System

Step 1: Prepare for the Upgrade

Before you begin, ensure you have all the necessary tools and replacement parts. You'll need:

- Replacement roller wheels (make sure they're compatible with your shower door system)

- Screwdrivers (Phillips or flathead, depending on the screws used)

- Pliers

- Measuring tape (to verify wheel size compatibility)

- Lubricant (optional, silicone-based for smoother operation)

- Cleaning supplies (cloth, mild soap, or vinegar-water solution for cleaning the track)

Step 2: Remove the Shower Door

- Open the Door Fully: Slide the shower door open to access the top and bottom roller wheels.

- Lift the Door Off the Track: Most shower doors will have screws or clips holding the door in place. Loosen these screws with a screwdriver to release the door from the track. Some systems may require you to lift the door off the track entirely.

- Place the Door on a Flat Surface: Once the door is detached, carefully place it on a flat, padded surface like a towel or soft cloth to avoid scratching or damaging the door.

Step 3: Remove the Old Roller Wheels

Inspect the Roller Wheels: Look at the existing roller wheels and determine how they’re attached. Typically, roller wheels are secured by screws or clips.

- Remove the Screws or Clips: Use a screwdriver or pliers to carefully remove any screws, bolts, or clips holding the old wheels in place.

- Take Out the Old Roller Wheels: Once the screws are removed, take out the old wheels. Pay attention to how the wheels were attached, as you'll need to replicate this setup with the new wheels.

Step 4: Clean the Track and Door

- Clean the Track: Use a cloth and mild cleaning solution to remove any debris, soap scum, or water buildup from the shower door track. A clean track ensures smooth, frictionless operation.

- Check the Door for Damage: Inspect the door for any signs of damage or wear, especially around the area where the wheels were attached. This is also a good time to ensure the track alignment is still straight.

Step 5: Install the New Plastic Roller Wheels

- Align the New Roller Wheels: Take the new plastic roller wheels and align them with the corresponding attachment points on the shower door.

- Secure the Wheels: Attach the new wheels by either tightening screws or securing clips. Ensure that each wheel is snugly fitted into its slot and rotates freely.

- Check the Wheel Movement: Before reattaching the door to the track, manually rotate the new wheels to ensure they move smoothly. If the wheels do not rotate freely, loosen the screws slightly or realign them.

Step 6: Reinstall the Shower Door

- Lift the Door Back Into Position: Carefully lift the door back into place on the track, making sure the wheels fit into the upper and lower tracks.

- Secure the Door: Once the door is aligned, fasten any screws or clips to secure the door in place.

- Test the Movement: Slide the door back and forth several times to check for smooth movement. The door should glide easily without resistance or noise. If needed, adjust the tension of the wheels to achieve a perfect fit.

Tools and Tips for Ensuring Proper Installation

Tools You'll Need:

- Screwdrivers: A Phillips or flathead screwdriver depending on the screws used in your system.

- Pliers: To remove clips or stubborn screws.

- Measuring Tape: Verify the size and diameter of the roller wheels to ensure compatibility with your track.

- Lubricant: Silicone-based lubricant can help the roller wheels glide more smoothly and reduce friction.

- Cloth and Cleaner: For cleaning the track and door components during the upgrade.

Installation Tips:

- Double-Check Compatibility: Ensure that the replacement roller wheels are the correct size and material for your shower door system. This will prevent any issues with misalignment or improper movement.

- Align the Wheels Properly: Be sure to line up the wheels with the track and attachment points correctly. Misalignment can lead to poor performance and damage to both the door and the track system.

- Avoid Over-tightening: When securing the wheels with screws, avoid over-tightening them, as this can damage the plastic or lead to unnecessary stress on the components.

Common Installation Mistakes to Avoid for Optimal Performance

- Incorrect Wheel Size: One of the most common mistakes is selecting roller wheels that are too large or too small for the track. Always measure the diameter and width of the old wheels before purchasing replacements.

- Misaligned Track: If the track is not level or straight, the roller wheels will not function properly. Ensure the track is aligned and clear of debris before reinstalling the door.

- Skipping the Lubrication Step: Even though plastic roller wheels require less lubrication than metal wheels, a small amount of silicone-based lubricant can help reduce friction and noise.

- Reusing Damaged Parts: If any part of the roller wheel assembly is damaged, it's essential to replace the entire unit. Using worn-out components can affect the performance and longevity of your shower door system.

Maintaining Your Plastic Roller Wheels for Long-Term Performance

Once your new plastic roller wheels are installed, proper maintenance will ensure they continue to function smoothly for years to come. Here’s how to keep them in top shape:

Best Practices for Maintaining Roller Wheels to Ensure Smooth, Reliable Operation

Regular Cleaning

- Periodically clean the roller wheels and tracks to remove dirt, soap scum, or other debris that can create friction or interfere with smooth operation. Use a soft cloth and mild cleaning solution to gently wipe the wheels and tracks. Avoid harsh chemicals that could degrade the plastic material.

Lubricate the Tracks

- Light lubrication of the track system helps reduce friction and ensures smooth movement. Apply a small amount of silicone-based lubricant to the tracks, being careful not to over-lubricate, as excess lubrication can attract dirt and dust.

Check for Wear and Tear

- Every few months, check the condition of the roller wheels. Look for cracks, chips, or signs of wear that might affect their functionality. Early detection of wear can help prevent the need for a full system replacement.

Adjust the Roller Wheels

- If your shower door starts to feel uneven or difficult to slide, it might be time to adjust the tension of the roller wheels. This can usually be done by tightening or loosening the screws on the wheel housing.

Cleaning and Care Instructions to Prevent Wear and Tear

- Avoid Harsh Chemicals: Use only mild soap or a vinegar-water solution to clean the wheels and track. Avoid abrasive cleaners that can scratch or damage the plastic.

- Dry the Tracks Regularly: After cleaning, dry the tracks with a cloth to prevent water buildup that could cause the wheels to deteriorate.

- Remove Debris: Periodically check for any debris that may have accumulated in the tracks and remove it to maintain smooth operation.

- Troubleshooting Tips for Minor Issues

- Squeaky or Noisy Wheels: This often occurs when there's too much friction. Cleaning the tracks and applying a small amount of silicone lubricant can resolve the issue.

- Sticking or Stiff Door Movement: If the door is sticking or difficult to move, check the alignment of the wheels and tracks. You may need to readjust the roller wheel tension or clean the track.

- Uneven Door Movement: If one side of the door is not moving smoothly, inspect the wheels for damage. If the wheels are fine, check the track for misalignment.

Is Your Shower Door System Ready for an Upgrade?

If you're noticing signs of wear or poor performance in your shower door system, it may be time to upgrade the roller wheels for a smoother, more reliable experience. Hune Plastic Roller Wheels for Curved Bathroom Shower Doors are designed to provide long-lasting durability and optimal performance in both curved and straight shower door systems.

At Hune, we specialize in providing high-quality plastic roller wheels that ensure smooth operation, reduced friction, and resistance to wear. As a trusted plastic roller wheels manufacturer, we offer solutions that are perfect for upgrading your shower door system and maintaining its long-term performance.

If you're considering an upgrade, choose Hune Plastic Roller Wheels for Curved Bathroom Shower Doors—your reliable partner for high-quality, durable, and easy-to-install shower door solutions.

FAQ About Plastic Roller Wheels for Curved Bathroom Shower Doors

What Are Plastic Roller Wheels for Curved Shower Doors?

- Plastic roller wheels are small but essential components that help a curved shower door slide smoothly along its track. They are typically made from durable plastic materials like nylon or polycarbonate, offering a quiet, reliable glide.

How Do Plastic Roller Wheels Work in a Curved Shower Door System?

- Plastic roller wheels enable the shower door to slide effortlessly along curved tracks. The wheels are attached to the top and bottom of the door, reducing friction and allowing for smooth, continuous movement.

How Do I Choose the Right Size of Plastic Roller Wheels for My Shower Door?

- Measure the diameter and width of the existing roller wheels to ensure the replacement wheels are compatible with your track system. The wheel size should match the track's groove for smooth, stable operation.

What Are the Benefits of Plastic Roller Wheels Over Metal Wheels?

- Plastic roller wheels offer several advantages, including lower friction, lighter weight, quieter operation, and resistance to rust and corrosion. Plastic wheels are also better for humid environments, such as bathrooms.

How Do I Maintain My Plastic Roller Wheels to Ensure Long-lasting Performance?

- Regular cleaning and lubrication of the wheels and tracks are key to maintaining their performance. Periodically check for dirt and debris, apply silicone-based lubricant to the tracks, and inspect the wheels for signs of wear.

What Types of Shower Doors Use Plastic Roller Wheels?

- Plastic roller wheels are typically used in sliding shower doors. They are ideal for curved shower doors that move along a circular or semi-circular track, offering smooth operation and reducing the strain on the door frame.

Do Plastic Roller Wheels Prevent Shower Doors From Rusting?

- Yes, unlike metal wheels, plastic roller wheels are resistant to rust and corrosion. This makes them an ideal choice for shower doors in a high-humidity environment like the bathroom.

Can Plastic Roller Wheels Be Adjusted?

- Yes, many plastic roller wheels have adjustable tension settings, allowing you to fine-tune the door's movement. This feature ensures the wheels are tightly secured and properly aligned with the track.

Why Should I Choose Hune Plastic Roller Wheels for My Curved Shower Door?

- Hune Plastic Roller Wheels are manufactured with high-quality materials designed for durability, smooth operation, and long-term performance. As a professional manufacturer, Hune offers tailored solutions to fit your specific shower door system, providing reliability and ease of installation.

English

English  Español

Español  日本語

日本語