Over the past few years, we have diligently pursued higher standards to enhance our product quality, aiming to deliver increased convenience and a better user experience.

-

0㎡Plant Area

0㎡Plant Area -

0+Staff

0+Staff -

0Established in

0Established in -

0+Exporting Countries

0+Exporting Countries

Cabinet & Wardrobe Sliding Door Roller: The Key to Smooth and Silent Door Operation

In the realm of modern interior design, the functionality of furniture often takes center stage alongside aesthetics. Among the many innovations that have transformed our living spaces, the sliding door system stands out for its practicality and style. At the heart of this system lies the sliding door roller, a seemingly simple yet crucial component that ensures your cabinets and wardrobes operate smoothly and silently. Imagine effortlessly gliding open your wardrobe doors without the creaks or jolts that can disrupt your peaceful environment. But what makes these rollers so essential for achieving that seamless experience in your home?

The Role of Sliding Door Rollers

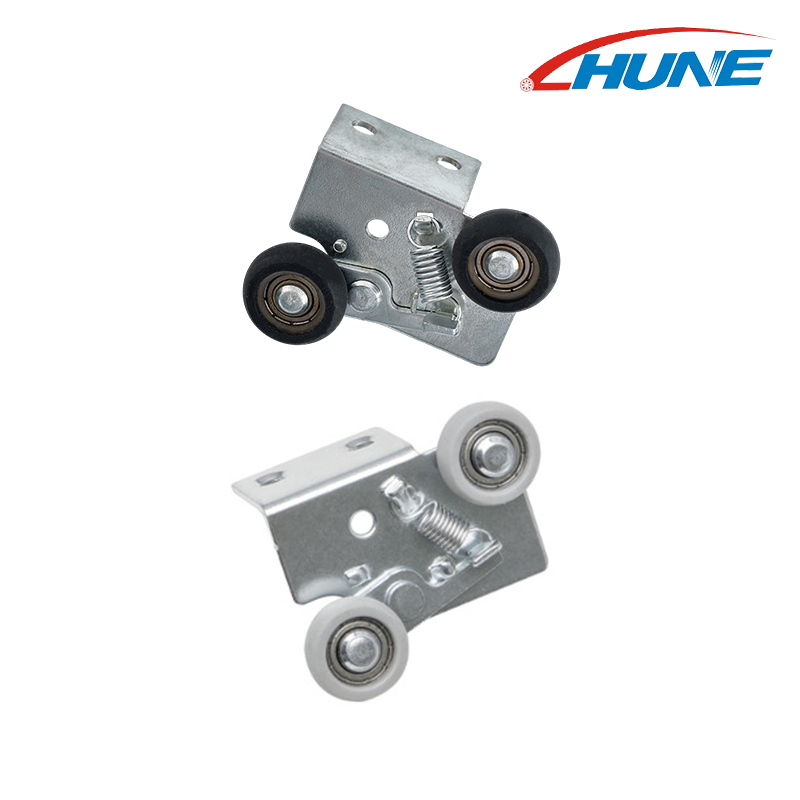

A premium sliding door roller isn't just a wheel on an axle. It's a miniature engineering system:

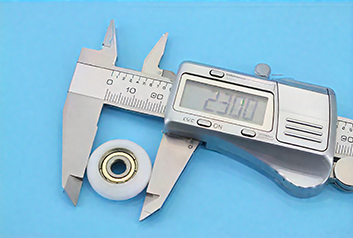

- Precision stainless-steel ball bearings that stay sealed against dust and wardrobe lint

- A high-strength POM or nylon tire that resists flattening under constant load

- A suspension spring or height-adjustment mechanism that keeps the door perfectly level even when floors settle

- A quiet outer coating (often rubberized or soft polyamide) that eliminates vibration and noise

- An anti-jump pin that prevents the door from derailing when children swing on it

- When all five elements work together, the result is a door that opens with one finger and closes with a satisfyingly soft click—no rattles, no grinding, no drama.

Benefits of Sliding Door Rollers

- Smooth Operation: One of the primary advantages of sliding door rollers is their ability to provide a smooth operation. Unlike traditional hinged doors that can squeak or catch, sliding doors equipped with quality rollers glide seamlessly along their tracks. This smooth operation is particularly beneficial in spaces where noise reduction is a priority, such as bedrooms or home offices.

- Space Efficiency: Sliding doors are an excellent space-saving solution. They do not require the clearance needed for swinging doors, making them ideal for smaller rooms or tight areas. With sliding door rollers, you can maximize your available space while still enjoying functional storage options. This feature is especially valuable in urban living environments where every square foot counts.

- Aesthetic Appeal: Sliding doors add a modern touch to any room. They are available in various styles, materials, and finishes, allowing homeowners to customize their appearance to match their decor. Whether you prefer sleek glass panels or warm wooden finishes, sliding doors can enhance the overall aesthetic of your space.

- Versatility: Sliding door rollers are versatile and can be used in various applications, from wardrobes to kitchen cabinets and room dividers. This adaptability makes them suitable for different areas of the home, providing flexible storage solutions that can fit any design scheme.

- Durability: Quality sliding door rollers are designed to withstand frequent use without compromising performance. Made from robust materials, they can endure the wear and tear associated with daily operation. Investing in high-quality rollers ensures longevity and reduces the need for frequent replacements.

The Hidden Cost of Cheap Rollers

Many budget wardrobes ship with rollers that cost less than a cup of coffee. They use open bearings that fill with dust in six months, soft plastic wheels that deform under weight, and no damping whatsoever. The door works fine in the showroom, but by month eight you're lifting the panel slightly every time you open it to "help" the struggling wheels. By year two, the track is scratched, the door sags, and the whole unit feels cheap—no matter how expensive the wood veneer was.

Replacing those rollers later is rarely simple. Tracks get damaged, screw holes strip, and the new premium rollers often don't fit the old cheap housing. What started as a $6 saving becomes a $300–600 repair or complete wardrobe replacement.

Real-Life Performance Differences

Top-tier rollers (rated for 80–120 kg and 100,000+ cycles) keep running smoothly for 15–20 years. That's roughly 40,000 openings—more than enough for daily use by a family of four across an entire childhood. They stay quiet even in humid climates, resist corrosion in coastal homes, and maintain their height adjustment so the door never scrapes the floor.

Lower-grade rollers rarely survive past 20,000–30,000 cycles before noise and resistance become unbearable.

Soft-Close and Safety Features

Modern rollers often integrate soft-close dampers directly into the wheel housing. The door glides the last few centimeters on its own and stops with a gentle hush—no slammed fingers, no shaken walls. Some systems even include anti-lift security pins, making it nearly impossible for a child to pull the door off the track.

When everything is said and done, the true measure of a quality wardrobe or cabinet isn't the finish, the mirror, or even the price tag; it's how effortlessly and quietly the door moves ten years from now. A perfectly smooth, whisper-silent glide every single time isn't a happy accident; it's the direct result of choosing rollers engineered for real life: sealed precision bearings, high-wear POM or nylon wheels, and load ratings that laugh at heavy mirrored panels.

At Hune, we are committed to delivering exceptional furniture solutions that incorporate innovative design and reliable components. Our sliding door rollers are engineered for durability and performance, ensuring that your cabinets and wardrobes operate seamlessly for years to come. Whether you're renovating your home or designing a new space, investing in quality sliding door systems from Hune can transform your everyday experience. So, why settle for anything less than the smoothest operation for your furniture?

English

English  Español

Español  日本語

日本語