Over the past few years, we have diligently pursued higher standards to enhance our product quality, aiming to deliver increased convenience and a better user experience.

-

0㎡Plant Area

0㎡Plant Area -

0+Staff

0+Staff -

0Established in

0Established in -

0+Exporting Countries

0+Exporting Countries

Everything You Need to Know About 2" and 3" Silent Sliding Garage Door Nylon Rollers with Carbon Steel Stems

In garage door performance, the door hinge serves as the unsung core, securely connecting all components and playing a vital role in overall functionality. Carbon steel door hinges, known for their exceptional strength and durability, are the preferred choice for high-quality garage door systems. Their excellent tensile strength effectively prevents bending or deformation under heavy loads, maintains precise component alignment, and ensures smooth, long-term operation of the garage door.

Compared with aluminum or plastic alternatives, carbon steel—when professionally coated or electroplated—offers significantly enhanced wear resistance, fatigue resistance, and corrosion resistance. This makes it ideal for both residential and commercial garage doors. Moreover, carbon steel provides solid support for precision bearings, maintaining operational balance even after thousands of opening and closing cycles. It also minimizes vibration, ensuring the garage door remains stable, reliable, and durable over time.

The Role of Bearings in Creating Smooth and Silent Sliding Garage Door Movement

The secret behind a quiet, effortless garage door lies in its bearings. Premium garage door rollers use caged or sealed bearings to minimize friction and noise during movement. These bearings distribute weight evenly across the roller, allowing it to glide smoothly along the track. With proper lubrication and protection from dust or moisture—often ensured by built-in dust shields—bearings significantly reduce wear on both the rollers and the door mechanism. Together, high-grade carbon steel stems and precision bearings form a perfect synergy, delivering stability, silence, and reliability for years of maintenance-free operation.

Top Benefits of Upgrading to Silent Nylon Bearing Rollers for Garage Doors

1. Quieter Operation

- Replacing old metal rollers with nylon bearing rollers drastically reduces noise. The combination of nylon's vibration absorption and high-quality bearings ensures whisper-quiet door movement, enhancing home comfort.

2. Smoother Door Motion

- Nylon rollers glide along tracks with minimal friction, which reduces jerking or uneven movement. The smooth operation also protects other components like hinges, tracks, and the garage door opener motor.

3. Longer Lifespan and Reduced Maintenance

- Silent nylon bearing rollers are durable and low-maintenance. Sealed bearings prevent dust and debris from entering, while nylon wheels resist wear and cracking. Homeowners spend less on frequent replacements or repairs.

4. Energy Efficiency

- Smoother rollers reduce the effort required by the door opener, which can lower energy consumption for automatic doors. This is particularly beneficial in commercial or high-traffic garage doors.

5. Enhanced Safety

- Even movement and stable door operation reduce the risk of door misalignment or accidental slamming, protecting both people and vehicles.

6. Ideal for All Environments

- Nylon rollers paired with carbon steel stems are resistant to humidity, moisture, and corrosion, making them suitable for indoor and outdoor garage settings, including coastal areas.

7. Compatibility with Standard Garage Doors

- Available in 2" and 3" sizes, silent nylon bearing rollers can fit most residential and commercial garage doors, offering a reliable upgrade without needing track modifications.

Silent Garage Door Rollers: Advantages at a Glance

|

Benefit |

Key Point |

|

Quiet |

Nylon + bearings reduce noise. |

|

Smooth Motion |

Minimal friction, protects hardware. |

|

Durable |

Nylon wheels + sealed bearings last longer. |

|

Energy Saving |

Less effort for door opener. |

|

Safe |

Stable, prevents misalignment/slamming. |

|

All Environments |

Resistant to moisture and corrosion. |

|

Compatible |

Fits most 2" & 3" garage doors. |

Applications and Use Scenarios of Silent Nylon Garage Door Rollers

1. Common Uses in Sectional, Overhead, and Automatic Garage Doors

Silent nylon bearing rollers with carbon steel stems are designed for smooth, low-friction operation, making them ideal for a wide variety of garage door systems. They are commonly used in:

- Sectional doors, where precise alignment and quiet operation are essential for daily use.

- Overhead doors, ensuring balanced movement and preventing wear on tracks and hinges.

- Automatic or motorized garage doors, where rollers must minimize friction and noise to allow seamless, energy-efficient operation.

By integrating high-quality nylon wheels and precision bearings, these rollers enhance door reliability while reducing operational strain on the garage door opener and other mechanical components.

2. Residential vs. Commercial Applications

These rollers are versatile and suitable for both residential and commercial garage doors:

- Residential use: Homeowners benefit from quiet, smooth operation, reduced vibration, and minimal maintenance. Ideal for garages that open multiple times daily without disturbing household peace.

- Commercial use: In industrial or commercial environments, rollers must withstand heavier door panels, frequent cycles, and continuous operation. Nylon rollers with carbon steel stems provide the necessary strength, durability, and long-term reliability for high-traffic applications.

This versatility makes them a preferred choice for apartment complexes, retail facilities, warehouses, and private residences alike.

3. Environmental Benefits: Reduced Vibration and Noise Pollution

Silent nylon rollers contribute to a more comfortable and eco-friendly environment:

- Noise reduction: Nylon wheels absorb vibration and eliminate the squeaking or rattling commonly associated with metal rollers, creating a quieter operation both indoors and outdoors.

- Reduced mechanical strain: Smooth, low-friction rolling reduces wear on door tracks and hardware, extending the lifespan of the door system and lowering the frequency of replacements.

- Energy efficiency: Less friction means the door opener uses less energy during operation, which is particularly valuable in automated or high-cycle commercial systems.

Upgrading to silent nylon bearing rollers not only enhances performance but also promotes sustainability and environmental comfort.

Quick Overview: Uses and Advantages of Nylon Bearing Rollers

|

Category |

Key Points |

|

Common Uses |

Sectional, overhead, and automatic doors; smooth, low-friction operation; reduces strain on opener. |

|

Residential vs. Commercial |

Residential: quiet, smooth, low-maintenance; Commercial: supports heavy doors, frequent use, high durability. |

|

Environmental Benefits |

Reduces noise and vibration; lowers wear on tracks; improves energy efficiency; eco-friendly. |

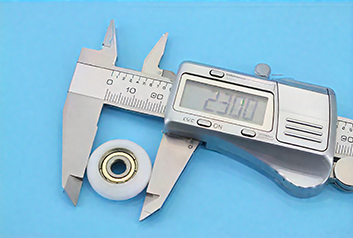

2" vs 3" Garage Door Rollers: How to Choose the Right Size for Your Door

Choosing the correct roller size is crucial for smooth, safe, and long-lasting garage door operation. The two most common sizes, 2-inch and 3-inch rollers, are widely used in residential and commercial garage doors. Selecting the wrong size can lead to misalignment, increased noise, faster wear, and potential damage to the door system.

Key Differences Between 2 Inch and 3 Inch Garage Door Rollers

a. Dimensional Considerations

- 2-inch rollers are smaller in diameter, making them suitable for standard residential garage doors. They fit most tracks and offer easy installation.

- 3-inch rollers are larger and better suited for heavier or taller doors, such as industrial or commercial garage doors, providing greater stability and load-bearing capacity.

b. Load-Bearing Capacity

- 2" rollers: Ideal for lighter doors up to typical residential weight limits.

- 3" rollers: Can support heavier doors, multiple panels, and higher-cycle usage in commercial settings.

c. Noise and Smoothness

- While both sizes can be equipped with nylon wheels and precision bearings, larger rollers may offer even smoother operation under heavier loads.

How to Determine the Right Roller Size?

- Check the door weight and panel count: Heavier doors typically benefit from 3" rollers.

- Inspect existing track width: Ensure compatibility with the roller diameter.

- Consider usage frequency: High-traffic doors may require larger rollers for durability.

- Consult manufacturer specifications: Always follow the door or track manufacturer's recommendations.

Installation and Maintenance Tips for Long-Lasting Garage Door Rollers

Why Proper Installation and Maintenance Matter

- By following proper installation and maintenance practices, you can extend the lifespan of your rollers, reduce maintenance costs, and enhance overall door performance.

Step-by-Step Guide to Replacing or Installing Rollers

Replacing or installing garage door rollers is straightforward if done carefully. Follow these steps for safe and efficient installation:

Prepare the Workspace

- Ensure the garage door is fully closed.

- Disconnect automatic openers for safety.

- Gather necessary tools: socket wrench, pliers, and lubrication.

Remove Old Rollers

- Loosen the brackets holding the roller stem.

- Slide the old roller out of the track carefully.

Inspect the Track and Hardware

- Check for bends, dents, or debris in the track.

- Replace any damaged brackets or hardware before installing new rollers.

Install New Rollers

- Insert the roller stem into the bracket.

- Ensure the roller wheel sits properly on the track.

- Tighten brackets securely but avoid over-tightening, which can restrict movement.

Test the Door

- Manually move the door up and down to ensure smooth operation.

- Reconnect the automatic opener and test for proper function.

Easy Step-by-Step Guide to Garage Door Roller Installation

|

Step |

Key Actions |

|

Prepare Workspace |

Close door, disconnect opener, gather tools. |

|

Remove Old Rollers |

Loosen brackets, slide rollers out carefully. |

|

Inspect Track & Hardware |

Check for bends/damage; replace if needed. |

|

Install New Rollers |

Insert stem, align wheel on track, tighten brackets. |

|

Test Door |

Move door manually, reconnect opener, ensure smooth operation. |

Lubrication and Cleaning Practices for Longer Lifespan

Proper maintenance keeps rollers quiet, smooth, and durable:

Lubrication

- Apply silicone-based or lithium grease to bearings and stem tips.

- Avoid heavy oil or petroleum-based lubricants that attract dust and dirt.

Cleaning

- Remove dust, debris, and old lubricant from rollers and tracks.

- Wipe down the rollers and stem regularly to prevent buildup.

Inspection

- Check bearings, wheels, and stems for signs of wear or misalignment.

- Replace any damaged parts immediately to prevent further damage.

Warning Signs That Indicate Roller Wear or Damage

Early detection of roller issues prevents costly repairs. Watch for:

- Excessive Noise: Squeaking, grinding, or rattling may indicate worn bearings or damaged wheels.

- Wobbling or Misalignment: Rollers not running straight on the track can cause uneven door movement.

- Visible Cracks or Chips: Nylon wheels or stems showing cracks reduce performance and safety.

- Slow or Jerky Movement: Increased resistance suggests worn rollers or insufficient lubrication.

- Rust or Corrosion on Stems: Compromises structural integrity and can lead to failure.

Regular inspection and maintenance help identify these issues early and extend roller lifespan.

Choosing Reliable Garage Door Roller Manufacturers and Suppliers

Why Choosing the Right Supplier Matters

Garage door rollers are small but essential components that directly affect door performance, safety, and longevity. Selecting a reliable manufacturer or supplier ensures that you receive high-quality rollers, including 2" and 3" silent nylon bearing rollers with carbon steel stems, designed for smooth, quiet, and durable operation. Working with an unreliable supplier can result in low-quality materials, inconsistent sizes, and premature wear, leading to costly replacements and safety risks.

Key Factors to Consider When Choosing Manufacturers

a. Experience and Expertise

- Look for manufacturers with years of experience in garage door hardware production.

- Specialized manufacturers are more likely to deliver precision-engineered rollers that meet safety and performance standards.

b. Product Quality and Materials

- Ensure the rollers use high-grade nylon for the wheels and carbon steel for stems.

- Verify the bearings are sealed or caged for smooth, low-friction operation.

- High-quality materials reduce noise, vibration, and wear, extending the lifespan of your garage doors.

c. Certifications and Standards

- Check for ISO or industry-specific certifications, which indicate compliance with international quality and safety standards.

- Certified products are more reliable and perform consistently under heavy use.

Advantages of Choosing Reliable Manufacturers

- Consistent Product Quality: Ensures rollers are dimensionally accurate and meet performance specifications.

- Longer Roller Lifespan: High-quality materials and precision bearings reduce maintenance needs.

- Improved Safety and Performance: Properly manufactured rollers reduce the risk of door misalignment, noise, and operational failure.

- Cost Efficiency: Although higher-quality rollers may cost more upfront, they reduce replacement frequency and long-term maintenance costs.

Choosing a reliable garage door roller manufacturer or supplier is essential for ensuring quiet, smooth, and long-lasting door operation. By considering experience, material quality, certifications, and after-sales support, you can make an informed decision.

With Zhejiang Huaneng Micro Bearing Co., Ltd., customers receive certified, precision-engineered rollers, including 2" and 3" silent nylon bearing rollers with carbon steel stems, providing long-term performance, reduced maintenance, and enhanced safety for both residential and commercial garage doors.

FAQ about 2" and 3" Silent Garage Door Nylon Rollers with Carbon Steel Stems

What is the Difference Between 2-inch and 3-inch Rollers?

- The main difference is size and load capacity — 3" rollers handle heavier doors, while 2" rollers suit most residential doors.

What Makes Nylon Rollers Better Than Metal Rollers?

- Nylon rollers are quieter, lighter, and resistant to corrosion, unlike metal rollers that can rust or squeak.

Are These Rollers Suitable for All Types of Garage Doors?

- Yes, they fit most standard residential and commercial sectional garage doors with compatible track sizes.

Why Use Carbon Steel Instead of Stainless Steel?

- Carbon steel provides better hardness and load capacity at a more cost-effective price.

Do These Rollers Have Sealed Bearings?

- Yes, most models feature sealed or caged bearings to prevent dust and debris from entering.

Does Nylon Wear Out Easily?

- No — nylon is highly wear-resistant and can handle thousands of open-close cycles.

Are They Resistant to Corrosion?

- Yes, both nylon and carbon steel components are designed to resist rust and environmental damage.

Do They Improve Door Balance?

- Yes, precision bearings and smooth rotation help distribute weight evenly for balanced door movement.

Can They Make Old Garage Doors Quieter?

- Absolutely — replacing old metal rollers with nylon ones can significantly reduce operational noise.

Do I Need to Lubricate Nylon Rollers?

- Yes, light lubrication on the bearings and stem will extend lifespan and improve performance.

How Many Rollers Does a Standard Garage Door Need?

- Most sectional doors use 10–12 rollers depending on height and panel count.

Are They Compatible With All Garage Door Tracks?

- They fit standard 2" or 3" tracks — always check your door specifications before purchase.

How Can I Tell if My Rollers Need Replacement?

- Look for signs like noisy operation, wobbling, or visible wear on the wheels or stems.

Do Sealed Bearings Require Maintenance?

- No — sealed bearings are maintenance-free and protect against dirt and moisture.

How Often Should I Check or Replace My Rollers?

- Inspect every 6–12 months and replace if cracks, rust, or excessive play are found.

Can These Rollers Be Used in Humid or Coastal Areas?

- Yes — nylon and treated carbon steel perform well even in high-humidity environments.

Where Can I Buy Reliable 2" and 3" Nylon Bearing Rollers?

- From trusted suppliers or factories that specialize in garage door hardware manufacturing. Such as Zhejiang Huaneng Micro Bearing Co., Ltd..

English

English  Español

Español  日本語

日本語