A sliding door roller is a small but essential component of sliding doors and windows that enables smooth, effortless movement along the track. It consists of a wheel or set of wheels mounted on a metal or plastic housing, which fits into the bottom or top track of the door system. These rollers are designed to support the weight of the door, reduce friction, and ensure a quiet and efficient operation.

Sliding door rollers come in various materials, including aluminum, stainless steel, and engineered plastics, each offering unique advantages such as durability, corrosion resistance, or quiet performance. They are commonly used in residential, commercial, and industrial applications, from standard interior sliding doors to heavy-duty glass or patio doors.

Benefits of Installing the Right Sliding Door Rollers

Investing in high-quality sliding door rollers offers multiple advantages that enhance both functionality and longevity:

1. Smooth and Effortless Operation

- Premium rollers reduce friction and allow your doors to glide seamlessly, improving the user experience and preventing strain during daily use.

2. Enhanced Durability

- Durable rollers are built to withstand constant movement, weight, and exposure to environmental elements. High-quality materials such as stainless steel or reinforced nylon ensure long-lasting performance.

3. Noise Reduction

- Advanced rollers feature precision bearings and shock-absorbing mechanisms that minimize noise, delivering a quieter, more comfortable environment in your home or office.

4. Improved Safety

- Properly functioning rollers ensure doors remain stable and secure. This minimizes the risk of accidents, such as doors derailing or becoming difficult to operate, especially in homes with children or elderly residents.

5. Energy Efficiency

- High-quality rollers maintain proper door alignment and seal integrity, helping to prevent drafts. This contributes to a more energy-efficient home, reducing heating and cooling costs.

6. Low Maintenance

- Investing in the right rollers reduces the frequency of repairs and replacements, saving both time and money. Many modern rollers are corrosion-resistant and require minimal upkeep.

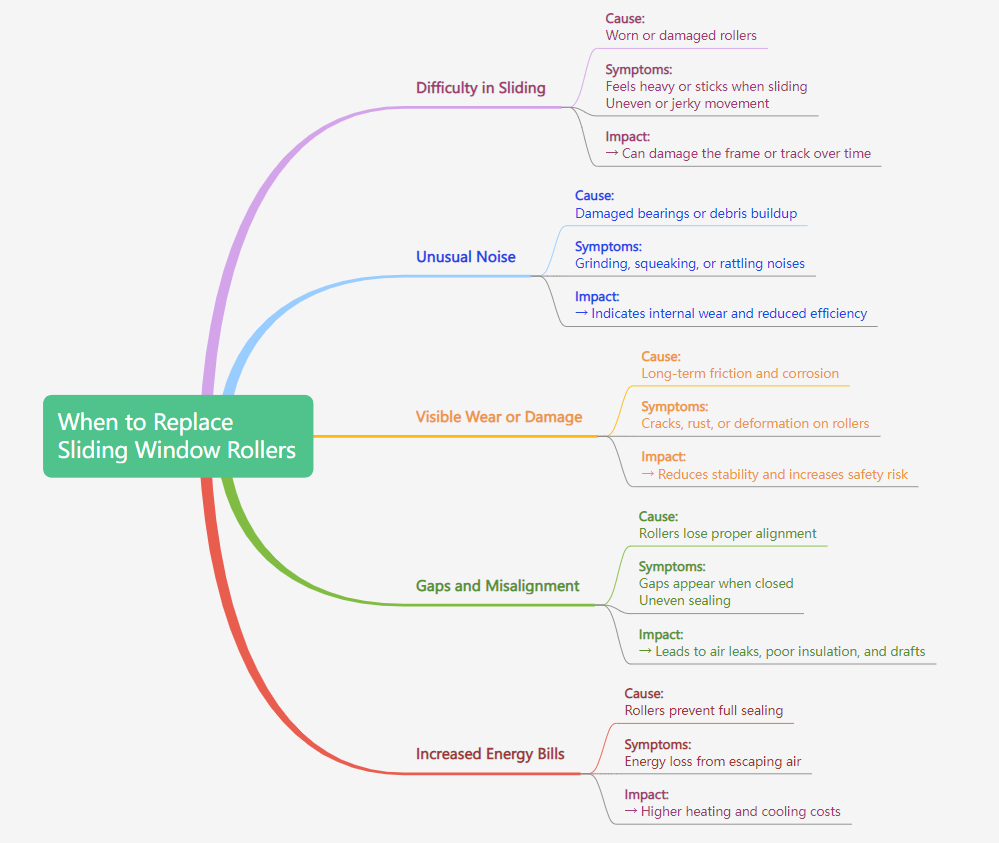

Signs You Need to Replace Your Sliding Window Rollers

Sliding window rollers endure constant movement, friction, and exposure to dust and debris. Over time, this can lead to malfunctioning and poor performance. Here are the most common signs that it's time for a replacement:

1. Difficulty in Sliding

- If your window or door feels heavy or sticks while moving, it's a clear indicator that the rollers are worn out. Worn rollers can cause uneven movement, making the sliding process laborious and potentially damaging the frame.

2. Unusual Noise

- Grinding, squeaking, or rattling sounds during operation signal that the rollers are failing. Noise often indicates that bearings are damaged, misaligned, or clogged with debris, which reduces overall efficiency.

3. Visible Wear or Damage

- Inspecting your rollers can reveal cracks, corrosion, or deformation. Damaged rollers compromise the window or door’s stability, potentially leading to safety hazards.

4. Gaps and Misalignment

- If you notice gaps when the window or door is closed, this could mean the rollers are no longer maintaining proper alignment. Misaligned rollers can lead to drafts, decreased insulation, and increased energy costs.

5. Increased Energy Bills

- Inefficient rollers may prevent windows from sealing properly, letting air escape. This not only affects comfort but also contributes to higher heating and cooling bills.

Why Good Sliding Door Rollers Make a Difference?

The quality of your sliding door rollers plays a big role in how well your door works. Top-notch rollers:

- Glide smoothly by reducing friction

- Protect the track from wear and tear

- Keep noise to a minimum

- Hold heavy glass panels safely without bending

- Last longer, meaning fewer replacements

Picking the right roller for your door type and usage can greatly extend your sliding door's life and performance.

Understanding the Different Types of Sliding Door Rollers

Sliding door rollers come in a variety of designs, materials, and configurations. Each type offers specific benefits depending on the application:

Ball Bearing Rollers

Best For: Heavy doors and high-traffic environments requiring smooth, quiet operation

Key Features:

- Precision ball bearings reduce friction for effortless sliding

- Supports higher weight capacities for commercial or industrial doors

- Quiet and smooth glide improves user experience

Why They Last:

- Ball bearings minimize wear on both rollers and tracks, ensuring long-term performance even with frequent use. Their durable construction keeps doors operating reliably over years of daily operation.

Nylon Rollers

Best For: Residential and light commercial doors that prioritize quiet operation and low maintenance

Key Features:

- Lightweight and corrosion-resistant for long-term durability

- Smooth glide reduces noise and friction

- Low-maintenance design saves time and costs

Why They Last:

- High-quality nylon resists wear and environmental damage, providing consistent performance with minimal upkeep. Their smooth operation reduces stress on the door system, extending its lifespan.

Stainless Steel Rollers

Best For: Harsh environments, including coastal or industrial settings, where corrosion resistance is critical

Key Features:

- Strong, durable stainless steel construction

- Resistant to corrosion, moisture, and chemical exposure

- Ideal for large or heavy sliding doors

Why They Last:

- Stainless steel rollers withstand extreme conditions without rusting or deforming, maintaining smooth operation and reliability over long periods.

Double Wheel Rollers

Best For: Large, heavy doors requiring enhanced stability and even load distribution

Key Features:

- Tandem wheel design spreads weight for smoother movement

- Reduces wear on tracks and rollers

- Improves alignment and stability for larger doors

Why They Last:

- Even load distribution prevents premature wear, maintaining alignment and reducing maintenance needs. The robust construction ensures years of trouble-free operation, even under heavy use.

Types of Sliding Door Rollers and Their Advantages

|

Roller Type |

Best For |

Key Features |

Why They Last |

|

Ball Bearing Rollers |

Heavy doors and high-traffic environments requiring smooth, quiet operation |

• Precision ball bearings reduce friction • Supports higher weight capacities • Quiet and smooth glide improves experience |

Ball bearings minimize wear on rollers and tracks, ensuring long-term reliability and smooth operation. |

|

Nylon Rollers |

Residential and light commercial doors that prioritize quiet and low maintenance |

• Lightweight and corrosion-resistant • Smooth glide reduces noise • Minimal maintenance required |

High-quality nylon resists wear and damage, providing long-lasting, quiet operation. |

|

Stainless Steel Rollers |

Harsh environments such as coastal or industrial settings |

• Strong and corrosion-resistant steel • Handles moisture and chemicals • Perfect for large or heavy doors |

Withstands corrosion and deformation, maintaining smooth, reliable performance over time. |

|

Double Wheel Rollers |

Large, heavy doors requiring stability and even weight distribution |

• Dual wheels ensure smooth movement • Reduces wear on tracks • Enhances door stability |

Even load distribution prevents premature wear and keeps doors aligned for years of steady use. |

How to Choose the Right Sliding Window Roller?

Choosing the right roller can prevent unnecessary wear, reduce maintenance costs, and improve overall window performance.

Measure Window and Track Specifications

Accurate measurements are critical:

- Roller Diameter: Ensure the roller fits snugly within the track. Too small, and it will wobble; too large, and it may not fit.

- Roller Width: Must match the track width to prevent misalignment or uneven sliding.

- Track Condition: Check for rust, dirt, or bends. A damaged track can shorten roller lifespan even if the roller is high-quality.

Always measure both the roller and track dimensions carefully before purchasing.

Consider Load Capacity and Durability

Sliding window rollers are rated for specific weight limits. Selecting a roller with insufficient load capacity can lead to poor performance or damage:

- Lightweight Windows: Nylon or standard steel rollers are sufficient.

- Heavy or Large Windows: Choose heavy-duty steel or ball bearing rollers to support the weight without strain.

- Environmental Factors: For windows exposed to moisture or outdoor conditions, opt for corrosion-resistant materials like stainless steel or coated rollers.

Durability and material quality directly influence the longevity and performance of your sliding windows.

Prioritize Smooth Operation and Noise Reduction

A key feature of high-quality sliding window rollers is smooth and quiet operation:

- Ball Bearings: Reduce friction and provide seamless sliding.

- Nylon or Polyurethane Wheels: Offer quieter performance compared to bare steel.

- Lubrication Options: Consider self-lubricating rollers for maintenance-free operation.

Smooth rollers not only enhance user experience but also prevent track damage over time.

Check Compatibility and Brand Reliability

Not all rollers are universal. Before purchasing, verify:

- Window Model Compatibility: Check manufacturer specifications to ensure the roller fits your window frame.

- Brand Reputation: Choose rollers from reliable manufacturers known for consistent quality. This helps avoid frequent replacements and ensures optimal performance.

High-quality, compatible rollers can extend the life of your sliding windows and reduce maintenance costs.

Installation and Maintenance Tips

Even the best roller can underperform if installed incorrectly.

- Proper Alignment: Misaligned rollers can cause the window to jam or derail.

- Clean Tracks: Remove debris and dirt before installation to ensure smooth operation.

- Regular Inspection: Periodically check rollers for wear, rust, or damage and replace as needed.

Proper installation and maintenance maximize roller performance and window longevity.

Hune: The Premier Sliding Window Roller Solutions for Businesses

With years of manufacturing experience, Hune specializes in producing high-quality sliding window rollers tailored for B2B clients. Hune’s products are designed for:

|

Feature |

Details |

|

Easy Installation |

Intuitive designs minimize installation time and reduce labor costs. |

|

Long-Term Reliability |

Premium materials and precision engineering ensure consistent performance. |

|

Wide Compatibility |

Suitable for commercial, residential, and OEM applications. |

Hune also offers support for custom specifications, from prototype development to bulk production. Choosing Hune means businesses gain dependable quality and expert guidance at every step, from design to delivery.

Sliding door rollers may be small components, but they are critical for smooth operation, safety, and durability. Understanding the different types and selecting the right roller for your business ensures long-term performance, reduces maintenance costs, and enhances user experience. With experienced suppliers like Hune, businesses can access high-quality rollers tailored to their specific requirements, guaranteeing reliable operation in any commercial or residential setting.

English

English  Español

Español  日本語

日本語