Over the past few years, we have diligently pursued higher standards to enhance our product quality, aiming to deliver increased convenience and a better user experience.

-

0㎡Plant Area

0㎡Plant Area -

0+Staff

0+Staff -

0Established in

0Established in -

0+Exporting Countries

0+Exporting Countries

Sliding Security Screen Door Rollers Industry Knowledge

Rolling wheels for sliding security screen doors play a crucial role in the performance, safety, and longevity of sliding doors. These seemingly simple components ensure that even heavy doors can glide smoothly along the tracks, enabling easy and convenient operation while maintaining security. Without high-quality rolling wheels, even the sturdiest security screen doors may become difficult to move, misaligned, or prone to premature wear and tear. The design of the rolling wheels minimizes friction, reduces stress on the door frame, and continuously supports the door's weight, thereby enhancing user convenience and the overall durability of the door system.

Beyond their functional benefits, these rolling wheels also contribute to improved safety. Smooth and precise sliding prevents the door from jamming or derailing, avoiding potential hazards or accidental injuries. Moreover, well-engineered rolling wheels can withstand daily use over extended periods, ensuring that sliding doors remain reliable in both residential and commercial settings.

Therefore, investing in high-quality rolling wheels for sliding security screen doors is not merely a matter of convenience—it is about protecting your property and ensuring the long-term stable operation of your door system. Whether in modern homes, offices, or commercial properties, these rolling wheels are the unsung “workhorses” that keep your security doors operating smoothly and efficiently.

What Are Sliding Security Screen Door Rollers?

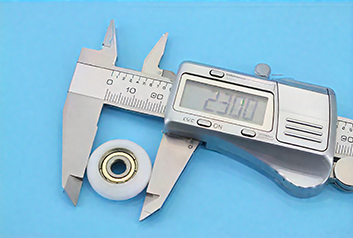

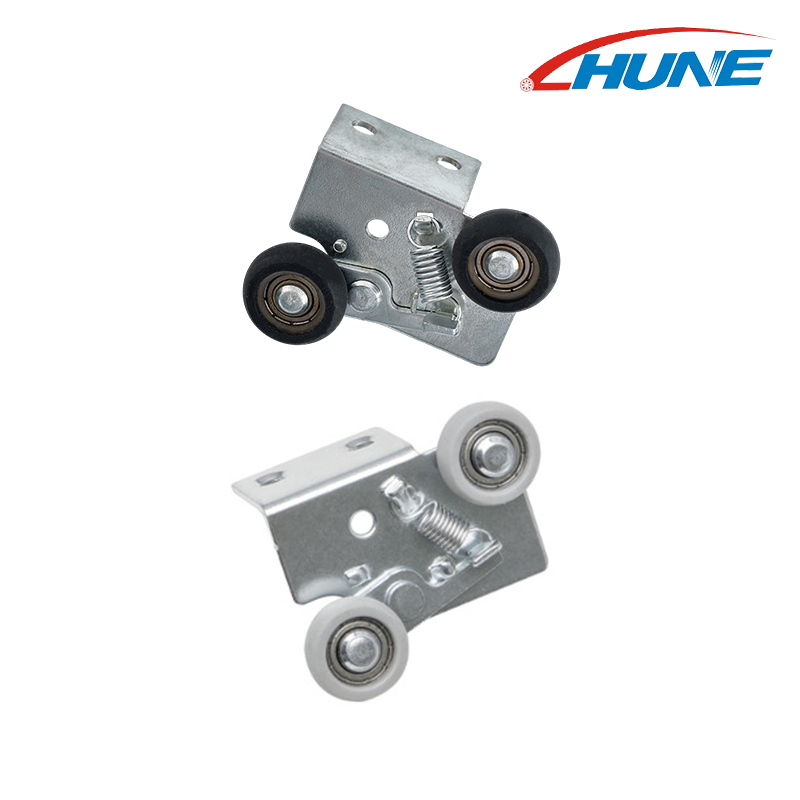

Sliding security screen door rollers are specialized mechanical components designed to facilitate the effortless movement of sliding doors. Typically mounted at the top or bottom of the door panel, these rollers allow the door to glide along a track with minimal friction. Unlike ordinary door rollers, those used in security screen doors are engineered to support heavier loads and resist wear, ensuring consistent performance even under frequent use.

These rollers consist of durable materials and precision bearings that allow smooth rotation while minimizing noise and vibration. They play a dual role: supporting the door's weight and enabling secure, controlled movement. High-quality rollers help maintain door alignment, prevent dragging or sticking, and ensure that the security screen performs optimally over time.

Sliding security screen door rollers are the backbone of any sliding door system. They combine engineering precision with durability to provide effortless functionality, maintain safety standards, and protect the longevity of your investment in security doors.

How to Adjust Rollers on a Security Screen Door?

Sliding doors are designed to provide smooth and effortless operation. However, over time, the rollers that support and guide these doors can wear out, misalign, or accumulate debris. Recognizing the early signs of roller issues can save you from costly repairs or replacement.

1. Door Dragging or Sticking Along the Track

- One of the earliest and most noticeable signs that your rollers are failing is when the door drags or sticks while opening or closing. Instead of gliding effortlessly, the door may require extra force or produce uneven movement. This can occur due to dirt and debris build-up in the track, worn-out rollers, or improper roller alignment. Ignoring this problem can lead to further damage to both the door and track, reducing overall lifespan.

Tip: Regularly clean the track and inspect rollers for smooth rotation to prevent dragging issues.

2. Uneven Movement or Wobbling

- If your sliding door wobbles or moves unevenly, it is often a clear indication that the rollers are misaligned or worn. Uneven motion not only affects usability but also compromises safety, as doors may suddenly jump off the track or become difficult to operate. This problem is particularly common in doors that see frequent use or carry heavy panels.

Tip: Check if the rollers rotate freely and adjust the height or alignment to stabilize the door.

3. Doors Misaligned With the Frame

- A properly functioning sliding door should sit flush within the frame. If you notice gaps at the top, bottom, or sides, or if the door seems tilted, the rollers are likely out of adjustment. Misalignment not only affects aesthetic appeal but also impacts insulation, security, and smooth operation. It is essential to realign the rollers promptly to restore proper door function.

Tip: Use the adjustment screws on the rollers to raise, lower, or level the door for precise alignment.

4. Noise or Scraping Sounds During Operation

- Sliding doors should operate quietly. Scraping, grinding, or squeaking noises are strong indicators that the rollers are worn, damaged, or obstructed. Continuous noise can lead to accelerated wear and potential failure of the door mechanism. Lubrication may help temporarily, but persistent noise usually requires roller inspection or replacement.

Tip: Inspect the rollers for wear, clean the track thoroughly, and consider applying a suitable lubricant to reduce friction.

Must-Have Tools and Materials for Smooth Roller Adjustment

Proper roller adjustment requires the right set of tools and materials to ensure safe, effective, and long-lasting results. Using inadequate or improvised tools can damage the rollers, door, or track.

1. The Right Tools That Make Roller Adjustment a Breeze

- To properly adjust sliding door rollers, you'll need screwdrivers, Allen keys, or other specialized adjustment tools depending on your door model. These tools allow you to fine-tune the height, alignment, and rotation of the rollers with accuracy. Using the correct tool not only makes the job easier but also prevents stripping screws or damaging roller components.

Tip: Keep a set of multiple screwdriver sizes and Allen keys on hand for versatility.

2. Lubricants and Cleaners: The Secret to Smooth-Gliding Doors

- Rollers often accumulate dust, dirt, and debris, which can hinder smooth operation. High-quality lubricants and cleaning solutions are essential for maintaining low-friction movement. Lubricants reduce wear and noise, while cleaning solutions remove build-up that can interfere with roller function. Regular maintenance with these materials extends the lifespan of your sliding doors.

Tip: Choose lubricants compatible with metal, plastic, or nylon rollers to avoid damage.

3. Door Lifters and Support Blocks: Your Safety Sidekick

- Sliding doors can be heavy, and improper handling during roller adjustments can cause injury or door misalignment. Support blocks, door lifters, or wedges help stabilize the door while you work, ensuring both safety and precision. They prevent sudden drops or shifts that could damage the track or roller system.

Tip: Always use at least two support points to evenly distribute the door's weight.

4. Protective Gear: Stay Safe While Working on Rollers

- Adjusting sliding door rollers may seem simple, but metal edges, heavy doors, and moving parts pose potential hazards. Wearing safety gloves and protective gear such as goggles or knee pads can prevent cuts, bruises, and other injuries. Safety should always be your top priority before starting any maintenance or adjustment work.

Tip: Ensure gloves fit well and allow full dexterity for tool handling.

Table: Must-Have Tools and Materials for Smooth Roller Adjustment

|

Item |

Purpose |

|

Tools |

Screwdrivers/Allen keys for safe, precise adjustment. |

|

Lubricant & Cleaner |

Keep rollers smooth and debris-free. |

|

Support |

Use lifters or blocks to stabilize heavy doors. |

|

Safety Gear |

Gloves and goggles protect while working. |

Preparing Your Security Screen Door for Roller Adjustment

Before attempting any roller adjustments, preparing your security screen door properly is crucial. Proper preparation ensures your safety, prevents damage to the door, and makes the adjustment process smoother.

1. Safety First: Precautions Before You Start

- Adjusting sliding security screen door rollers involves lifting and handling potentially heavy doors. Always wear protective gloves and safety goggles, and make sure the work area is clear of obstacles. Taking these precautions minimizes the risk of injury and protects both you and your door during the adjustment process.

Tip: Keep children and pets away from the work area for added safety.

2. Lift Like a Pro: Supporting the Door Safely

- To avoid strain or accidental damage, use door lifters, wedges, or support blocks to hold the door in place while working on the rollers. Properly supporting the door prevents sudden drops and ensures accurate alignment adjustments. This step is especially important for heavier security doors, which can be difficult to handle manually.

Tip: Always position support points evenly under the door to balance the weight.

3. Inspect for Trouble: Rollers and Tracks Check-Up

- Before making any adjustments, thoroughly inspect both the rollers and the tracks for signs of wear, misalignment, or debris. Look for cracked or worn rollers, bent tracks, or accumulated dirt that could hinder smooth operation. Identifying potential issues early helps avoid further damage and ensures a more effective adjustment.

Tip: Take note of any rollers that seem loose or noisy—they may need replacement rather than adjustment.

4. Clean Slate: Track Cleaning Before Adjustment

- A clean track is essential for smooth door operation. Dirt, dust, and debris can prevent rollers from moving freely and reduce the effectiveness of any adjustments. Use a vacuum, brush, or cloth to remove buildup, and consider applying a light lubricant afterward to enhance smooth sliding.

Tip: Avoid using harsh chemicals that may damage the track material or finish.

Table: Preparing Your Security Screen Door for Roller Adjustment

|

Step |

Instruction |

Tip |

|

Safety First |

Wear gloves and goggles; keep the area clear. |

Keep kids and pets away. |

|

Support the Door |

Use lifters, wedges, or blocks to stabilize heavy doors. |

Balance weight evenly. |

|

Inspect Rollers & Tracks |

Check for wear, misalignment, or debris. |

Note noisy or loose rollers—they may need replacement. |

|

Clean the Track |

Remove dirt and dust for smooth operation. |

Use gentle cleaners and consider light lubrication. |

Step-by-Step Guide to Adjusting Sliding Door Rollers

Proper roller adjustment is essential for smooth, quiet, and safe operation of sliding doors. Whether your door is sticking, wobbling, or making noise, following a systematic approach ensures effective results and prolongs the door's lifespan.

1. Know Your Door: Identify Roller Types and Locations

- Before making any adjustments, take time to identify the type of rollers your door uses and their exact locations. Most sliding doors feature bottom rollers, while some may also have top rollers. Understanding the roller system helps you plan the adjustment process and ensures you don’t damage the door or track.

Tip: Refer to the manufacturer's guide for specific roller types if available.

2. Smooth Moves Start Below: Adjusting Bottom Rollers

- The bottom rollers bear most of the door's weight, making them critical for smooth movement. Use the appropriate tool to adjust the height or alignment, allowing the door to glide effortlessly along the track. Small adjustments can make a big difference in reducing dragging, wobbling, or uneven motion.

Tip: Test the door after each adjustment to check for smooth operation before moving on.

3. Top It Off: Adjusting Top Rollers (If Applicable)

- Some sliding doors feature top rollers that help guide and stabilize the door. If your door has them, check for wear or misalignment and make necessary adjustments. Properly aligned top rollers prevent tilting, rubbing, or rattling, enhancing the door's overall stability and longevity.

Tip: Only adjust top rollers if the door design includes them—improper adjustment can cause binding.

4. Precision Matters: Fine-Tuning Roller Height and Tension

- Once basic adjustments are made, fine-tune roller height and tension for optimal performance. This ensures the door sits flush with the frame, moves silently, and operates with minimal effort. Over- or under-tightening can cause misalignment or unnecessary wear, so small, careful adjustments are key.

Tip: Make incremental changes and test the door repeatedly for smoothness.

5. Reinstall with Care: Putting the Door Back (If Removed)

- If the door was temporarily removed for easier access, reinstall it carefully after adjustments. Ensure it sits properly on the track, that all rollers are aligned, and that movement is smooth. Double-check that the door is level and secure before finishing the job.

Tip: Enlist help if the door is heavy—two people are safer than one.

Table: Step-by-Step Guide to Adjusting Sliding Door Rollers

|

Step |

Instruction |

Tip |

|

Identify Rollers |

Know roller types and locations. |

Check manufacturer’s guide if needed. |

|

Adjust Bottom Rollers |

Set height/alignment for smooth gliding. |

Test after each adjustment. |

|

Adjust Top Rollers |

Only if present; correct misalignment and wear. |

Avoid over-adjusting to prevent binding. |

|

Fine-Tune |

Optimize roller height and tension for quiet, smooth motion. |

Make small adjustments and retest. |

|

Reinstall Door |

Ensure rollers are aligned and door moves freely. |

Get help for heavy doors. |

Testing the Door After Roller Adjustment

After adjusting your sliding security screen door rollers, it's critical to test the door thoroughly. Proper testing ensures that adjustments were effective, the door operates smoothly, and potential issues are identified before they become major problems.

1. Glide Check: Smooth, Effortless Door Movement

- Start by opening and closing the door multiple times, observing how it glides along the track. A properly adjusted door should move smoothly without dragging, wobbling, or sticking. Uneven movement may indicate that roller height, alignment, or tension needs further fine-tuning.

Tip: Test the door at different speeds—slow movements reveal subtle issues, while faster motion checks overall stability.

2. Seal and Secure: Ensuring Proper Closure and Alignment

- Next, ensure the door aligns correctly with the frame and closes securely. Check for any gaps or misalignment that could compromise security, insulation, or energy efficiency. Properly seated doors provide a consistent seal, reducing drafts, noise, and potential security risks.

Tip: Inspect both the top and bottom edges for flush contact with the frame to ensure complete sealing.

3. Troubleshooting Post-Adjustment Issues

Minor issues may still appear even after careful adjustment. Common problems and quick fixes include:

- Slight dragging: readjust bottom roller height or tension.

- Squeaking or noise: clean the track and apply compatible lubricant.

- Door misalignment: verify support blocks and fine-tune top rollers if applicable.

Tip: Addressing issues immediately prevents accelerated wear and more costly repairs later.

Table: Testing the Door After Roller Adjustment

|

Step |

Instruction |

Tip |

|

Smooth Glide |

Open/close door; check for dragging, wobbling, or sticking. |

Test at slow and fast speeds. |

|

Proper Seal |

Ensure door aligns with frame and closes securely. |

Check top and bottom edges for flush contact. |

|

Troubleshoot |

Fix minor issues after adjustment: Dragging → adjust bottom rollers Noise → clean track & lubricate Misalignment → check support blocks/top rollers |

Address issues promptly to prevent wear. |

Maintenance Tips for Security Screen Door Rollers

Regular maintenance is key to keeping sliding security screen doors operating efficiently and extending roller lifespan. Proactive care prevents common problems such as sticking, wobbling, and premature roller failure.

1. Keep It Clean: Regular Cleaning and Lubrication

- Rollers and tracks accumulate dust, dirt, and debris over time, which can cause friction and reduce smooth operation. Clean the tracks with a brush or vacuum, and apply a light, compatible lubricant to rollers to ensure low-friction movement.

Tip: Avoid harsh chemicals that can damage metal or plastic rollers.

2. Check for Wear and Tear: Inspect Rollers Regularly

- Frequent inspection helps detect worn or damaged rollers early. Look for cracked, chipped, or bent rollers, and check for signs of misalignment or uneven wear. Identifying issues early reduces the risk of more serious damage.

Tip: Replace any damaged rollers promptly to maintain door safety and performance.

3. Schedule Adjustments: How Often to Fine-Tune Rollers

- Even with proper maintenance, rollers may gradually shift or wear. Regularly check and adjust roller height, alignment, and tension to ensure optimal performance. Scheduling adjustments every few months or after heavy use keeps the door gliding smoothly.

Tip: Maintain a maintenance log to track inspection dates and adjustments.

4. Avoid Common Mistakes That Cause Premature Roller Failure

Some practices can unintentionally reduce roller lifespan:

- Forcing the door when it sticks instead of checking rollers.

- Using inappropriate lubricants or cleaning chemicals.

- Neglecting regular cleaning or ignoring minor noise and misalignment.

Tip: Handle the door gently and perform routine maintenance to avoid costly repairs.

Table: Maintenance Tips for Security Screen Door Rollers

|

Step |

Instruction |

Tip |

|

Keep It Clean |

Remove dirt and debris; use light lubricant for smooth motion. |

Avoid harsh chemicals. |

|

Inspect Regularly |

Check for cracks, chips, or misalignment. |

Replace worn rollers promptly. |

|

Routine Adjustments |

Fine-tune height and alignment every few months. |

Keep a simple maintenance log. |

|

Avoid Mistakes |

Don't force the door or skip cleaning and lubrication. |

Gentle use extends roller life. |

How to Replace Sliding Screen Door Rollers

Signs You Need to Replace Your Sliding Door Rollers

Even with regular maintenance, sliding door rollers eventually wear out and need replacement. Recognizing the signs early helps prevent door damage, misalignment, and operational issues.

- Persistent Dragging or Sticking: If cleaning and adjusting no longer restore smooth movement, the rollers are likely worn.

- Excessive Noise: Grinding, squeaking, or scraping sounds that persist after lubrication indicate roller deterioration.

- Visible Damage: Cracks, chips, or bent rollers are clear signs that replacement is necessary.

- Door Misalignment: Doors that tilt, wobble, or fail to close properly often point to failing rollers.

Tip: Replacing worn rollers promptly maintains smooth operation and prevents additional stress on the track and door frame.

Essential Tools and Materials for Roller Replacement

Replacing rollers safely and effectively requires the right tools and materials. Having everything prepared before starting makes the process faster, safer, and more precise.

1. Basic Tools You'll Need

- You'll need screwdrivers, pliers, or Allen keys to remove old rollers and secure the new ones. Using the correct tool prevents damage to the screws, door, or roller components.

Tip: Keep multiple screwdriver sizes and Allen keys available to fit different roller designs.

2. Replacement Rollers

- Choose replacement rollers that match your door type, weight, and track system. Correctly sized rollers ensure smooth operation and prevent issues such as wobbling or misalignment.

Tip: If unsure, take an old roller to a hardware store to find an exact match.

3. Cleaning and Lubrication Supplies

- Cleaning cloths and a suitable lubricant are essential for preparing the track and rollers. Clean tracks remove dirt and debris that could hinder smooth movement, while lubrication reduces friction and noise.

Tip: Use lubricants compatible with the roller material—metal, plastic, or nylon—to avoid damage.

4. Optional Safety Equipment

- For heavy doors, a door lifter or support block can hold the door in place during roller replacement. This prevents accidents and makes the installation process easier.

Tip: Always use at least two support points to keep the door balanced and stable.

|

Step |

Instruction |

Tip |

|

Basic Tools |

Use screwdrivers, pliers, or Allen keys to remove and secure rollers. |

Keep various sizes handy. |

|

Replacement Rollers |

Match your door’s size, weight, and track system. |

Bring an old roller for comparison. |

|

Cleaning & Lubrication |

Clean tracks and apply compatible lubricant for smooth motion. |

Use materials safe for your roller type. |

|

Safety Equipment |

Use door lifters or blocks for stability when handling heavy doors. |

Support the door evenly with two points. |

Preparing the Sliding Screen Door for Roller Replacement

Proper preparation is the key to a safe and successful roller replacement. Taking the right steps before you start ensures smooth installation, prevents damage to the door, and keeps you safe throughout the process.

1. Take Safety Precautions First

- Before you begin, always prioritize safety. Wear protective gloves and goggles to prevent injuries from sharp edges or heavy parts. Clear the area around the door to avoid tripping hazards, and keep children and pets away while you work.

Tip: Having a second person assist can make handling heavy doors safer and easier.

2. Lift or Remove the Door Carefully

- For easier access to the rollers, you may need to lift the door off its track or partially remove it. Use a door lifter, wedges, or support blocks to stabilize the door during this process. Proper handling prevents damage to the track and keeps the door balanced.

Tip: Always lift from the base of the door and avoid twisting to prevent bending or warping.

3. Inspect the Track and Frame

- Before installing new rollers, check the track and frame for damage such as bends, dents, or cracks. Any imperfections can affect the door’s movement and cause premature wear on the new rollers. Fix minor damage or debris before proceeding with the installation.

Tip: Ensure the track is level and the frame is secure to guarantee smooth operation.

4. Clean the Track Thoroughly

- A clean track is essential for optimal roller performance. Remove dirt, dust, and debris using a brush or vacuum, and wipe down the track with a damp cloth if necessary. A clean, smooth surface allows the new rollers to glide effortlessly.

Tip: Avoid harsh chemicals that could damage the track material or finish.

|

Step |

Instruction |

Tip |

|

Safety First |

Wear gloves and goggles, clear the area, and keep kids or pets away. |

Get a helper for heavy doors. |

|

Lift Carefully |

Use lifters or blocks to remove or support the door safely. |

Lift from the base—don’t twist. |

|

Inspect Track & Frame |

Check for bends, dents, or cracks before installing new rollers. |

Make sure the track is level and secure. |

|

Clean the Track |

Remove dirt and debris for smooth gliding. |

Avoid harsh cleaning chemicals. |

Removing Old Rollers from a Sliding Screen Door

Replacing worn or damaged rollers is essential for maintaining smooth, safe, and reliable door operation. Proper removal techniques prevent damage to the door and frame while allowing you to inspect the old rollers for wear.

1. Find the Roller Mounting Points

- Start by locating where the rollers are attached to the door. Most sliding doors have screws or brackets at the bottom, and some may also have top rollers. Knowing the exact mounting points makes removal easier and helps prevent accidental damage.

Tip: Refer to your door's manual if available, or take a photo before removing the rollers to remember their placement.

2. Loosen Screws or Fasteners

- Use the appropriate screwdriver, pliers, or Allen key to carefully loosen the screws or fasteners holding the rollers in place. Take your time to avoid stripping the screws or damaging the roller brackets.

Tip: Keep all screws and small parts in a container so they don't get lost during the replacement process.

3. Remove Rollers Safely

- Once the fasteners are loose, carefully remove the rollers from the door. Avoid forcing them, as this can bend the track or damage the door frame. Use gentle wiggling or a flat tool to slide the rollers out if necessary.

Tip: Have a second person support the door if it's heavy to prevent accidental drops or misalignment.

4. Inspect Rollers for Wear and Alignment

- Before discarding the old rollers, inspect them for signs of wear such as cracks, chips, or flattened wheels. Also, check whether the rollers were previously misaligned, as this can indicate underlying issues with the track or door frame.

Tip: Take note of any recurring issues to address them when installing new rollers.

|

Step |

Instruction |

Tip |

|

Locate Mounting Points |

Find where rollers attach (usually bottom, sometimes top). |

Take a photo before removal for reference. |

|

Loosen Fasteners |

Use proper tools to remove screws or brackets carefully. |

Store small parts in a container. |

|

Remove Rollers |

Gently slide rollers out without forcing or bending the track. |

Have someone support heavy doors. |

|

Inspect Old Rollers |

Check for cracks, chips, or misalignment issues. |

Note problems to fix during installation. |

Installing New Rollers on a Sliding Screen Door

Proper installation of new rollers is essential for smooth, quiet, and long-lasting operation of your sliding screen door.

1. Pick the Right Roller

- Choose a replacement roller that matches your door type, track system, and weight. Using the correct roller ensures proper fit, smooth movement, and prevents damage to the door or track.

Tip: Bring the old roller to a hardware store to find an exact match if you’re unsure.

2. Put the Roller in Place

- Insert the new roller carefully into the mounting slot of the door frame. Make sure it fits securely without forcing it, which could damage the door or bracket.

Tip: Ensure the roller wheel sits fully in the track groove for optimal performance.

3. Align the Rollers

- Proper alignment is critical for smooth gliding. Check that the rollers are straight and parallel with the track. Misaligned rollers can cause the door to drag, wobble, or become noisy.

Tip: Use a level to make sure the door sits evenly on the track before tightening.

4. Secure the Rollers

- Tighten screws or fasteners to hold the rollers in place. Avoid over-tightening, which can deform the roller housing or track. Make sure all fasteners are secure but still allow minor adjustments if needed.

Tip: Keep screws organized and double-check that each roller is firmly attached.

5. Adjust Height and Tension

- After securing the rollers, adjust the height and tension to achieve smooth, effortless door movement. Fine-tuning ensures the door sits flush with the frame and glides quietly along the track.

Tip: Make small incremental adjustments and test the door repeatedly for optimal operation.

|

Step |

Instruction |

Tip |

|

Choose the Right Roller |

Match your door’s type, weight, and track system. |

Bring the old roller for comparison. |

|

Insert the Roller |

Place it gently into the mounting slot without forcing. |

Ensure the wheel sits fully in the track groove. |

|

Align Properly |

Keep rollers straight and parallel for smooth gliding. |

Use a level to confirm even placement. |

|

Secure Firmly |

Tighten screws just enough to hold rollers in place. |

Avoid over-tightening to prevent damage. |

|

Adjust Height & Tension |

Fine-tune for smooth, quiet movement. |

Make small adjustments and test frequently. |

Reinstalling the Sliding Screen Door

After installing new rollers, carefully reinstalling the door is essential to ensure smooth operation, proper alignment, and long-term reliability.

1. Put the Door Back on the Track

- Carefully lift and place the door back onto its track. Make sure both the top and bottom rollers sit securely in their respective grooves. Avoid forcing the door into place, as this can damage the track or roller mechanism.

Tip: Have a second person help with heavy doors to ensure safe handling and proper alignment.

2. Test the Door Movement

- Open and close the door several times to check for smooth gliding and proper alignment with the frame. A correctly reinstalled door should move effortlessly, without dragging, wobbling, or making unusual noises.

Tip: Test the door slowly first, then at a normal pace, to detect any subtle issues that might need adjustment.

3. Fine-Tune Rollers for Best Performance

- If the door does not glide perfectly or sits unevenly, adjust the roller height and tension as needed. Small incremental adjustments can make a significant difference in door performance, ensuring quiet, stable, and easy operation.

Tip: Recheck alignment after each adjustment and test multiple times to achieve optimal results.

|

Step |

Instruction |

Tip |

|

Reinstall Door |

Place door on track carefully; ensure rollers sit securely. |

Get help for heavy doors. |

|

Test Movement |

Open/close to check smooth gliding and proper alignment. |

Test slowly first, then at normal speed. |

|

Fine-Tune Rollers |

Adjust height and tension for quiet, stable operation. |

Recheck alignment after each adjustment. |

Testing and Troubleshooting Your Sliding Screen Door

After replacing rollers and reinstalling the door, it's important to test the door thoroughly and troubleshoot any issues.

1. Check for Noise, Wobbling, or Dragging

- Open and close the door several times, paying attention to unusual sounds or movements. Squeaks, scraping, or wobbling indicate that the rollers may need further adjustment, lubrication, or that debris remains in the track.

Tip: Move the door slowly and at a normal speed to detect both subtle and obvious issues.

2. Fix Common Issues After Replacement

Even after proper installation, minor problems may appear:

- Door drags: Check roller height and track for debris.

- Door wobbles: Ensure rollers are aligned and screws are secure.

- Noise: Apply a small amount of compatible lubricant or clean the track thoroughly.

Tip: Address problems immediately—small fixes prevent long-term damage.

3. Make Sure the Door Closes Securely and Evenly

- Check that the door sits flush with the frame when closed and that the seal is consistent along the edges. Proper closure prevents drafts, improves security, and ensures smooth operation.

Tip: Adjust roller tension and height as needed to achieve even closure.

|

Step |

Instruction |

Tip |

|

Check Movement |

Look for noise, wobbling, or dragging. |

Test slowly and at normal speed. |

|

Fix Minor Issues |

Adjust rollers, clean track, or lubricate as needed. |

Address problems immediately to prevent damage. |

|

Ensure Proper Closure |

Door should sit flush and seal evenly. |

Adjust roller height and tension for even closure. |

Maintenance Tips for Longevity of Sliding Screen Door Rollers

Proper maintenance is key to ensuring that sliding screen door rollers last as long as possible. Regular care reduces wear, keeps the door gliding smoothly, and prevents costly repairs or replacements.

1. Clean and Lubricate Regularly

- Dirt, dust, and debris can build up in the track and on the rollers, causing friction and reducing smooth operation. Clean the tracks and rollers with a brush or cloth, and apply a suitable lubricant to ensure quiet, effortless gliding.

Tip: Use lubricants that are compatible with the roller material—metal, plastic, or nylon—to prevent damage.

2. Inspect Rollers Periodically

- Regular inspection helps identify signs of wear, misalignment, or damage before they become serious problems. Check for cracks, chips, uneven rotation, or loose fasteners. Catching these issues early prevents unnecessary strain on the door and extends roller life.

Tip: Keep a maintenance log to track inspection dates and any adjustments made.

3. Extend the Life of Replacement Rollers

- Even newly installed rollers benefit from proactive care. Avoid forcing the door, keep the tracks clean, and make minor adjustments as needed. Proper alignment and gentle use significantly extend the life of your replacement rollers.

Tip: Test the door periodically to ensure rollers remain smooth and evenly aligned.

|

Step |

Instruction |

Tip |

|

Clean & Lubricate |

Remove dirt and debris; apply compatible lubricant. |

Use lubricant safe for metal, plastic, or nylon rollers. |

|

Inspect Rollers |

Check for wear, misalignment, or loose fasteners regularly. |

Keep a maintenance log. |

|

Care for New Rollers |

Avoid forcing the door, keep tracks clean, and adjust as needed. |

Test periodically for smooth, even operation. |

Signs Adjustment Alone Isn't Enough

Sometimes, small tweaks to roller height, tension, or alignment are enough to restore smooth operation. However, certain signs indicate that replacement is necessary rather than adjustment:

- Persistent Dragging or Sticking: If the door continues to drag or stick despite cleaning and adjustment, rollers are likely worn.

- Excessive Noise: Continuous squeaking, grinding, or scraping after lubrication signals damaged rollers.

- Visible Damage: Cracked, chipped, or bent rollers cannot be repaired by adjustment.

- Door Misalignment: Tilting, wobbling, or uneven closure often indicates rollers that have deteriorated beyond adjustment.

- Tip: Regular inspection helps you identify these issues early, avoiding further stress on the door and track.

Choosing the Right Sliding Security Screen Door Rollers

Factors to Consider

- Door Type and Weight: Rollers must be compatible with the size and weight of your door to support smooth movement.

- Track System: Ensure rollers match the groove type and size of your door track.

- Material Quality: Durable materials, such as nylon, metal, or a combination, resist wear and reduce noise.

- Roller Design: Some doors use adjustable rollers, while others require fixed types—choose according to your door's design.

Tip: When in doubt, take the old roller to a hardware store or consult the manufacturer for an exact match.

Maintaining smooth and reliable operation of your sliding security screen door starts with understanding when to adjust or replace its rollers. Minor misalignments or slight friction issues can often be resolved through careful adjustment. However, rollers that are worn, damaged, or producing noise should be replaced promptly to avoid further damage and ensure safe, effortless operation.

Selecting the right replacement rollers is critical. Hune offers a comprehensive range designed to match various door types, track systems, materials, and designs. Choosing the correct roller not only restores smooth gliding but also prolongs the life of your sliding door system.

Hune's rollers are engineered for durability, precision, and quiet operation, making them ideal for both residential and commercial sliding security screen doors. Regular inspection, timely adjustments, and high-quality replacements from Hune guarantee that your doors operate flawlessly for years, combining performance with peace of mind.

With Hune, upgrading or maintaining your sliding door rollers becomes a seamless experience—ensuring longevity, safety, and effortless gliding every time.

English

English  Español

Español  日本語

日本語