Over the past few years, we have diligently pursued higher standards to enhance our product quality, aiming to deliver increased convenience and a better user experience.

-

0㎡Plant Area

0㎡Plant Area -

0+Staff

0+Staff -

0Established in

0Established in -

0+Exporting Countries

0+Exporting Countries

How Customizable Low-Noise Sliding Rollers Improve Window and Door Performance: Installation, Benefits, and Maintenance Tips

We often say that the key factors in determining the performance of doors and windows are smooth sliding and noise levels. Customizable, low-noise sliding rollers are a valuable tool that can address these issues and comprehensively improve the performance of doors and windows. Some may wonder how these two features, "customization" and "low noise," contribute to the improved performance of doors and windows. Today, we'll discuss this in detail.

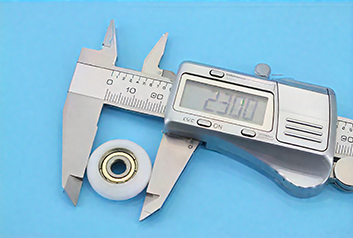

First, it's important to note that "customization" isn't simply about changing the dimensions; it allows for tailor-made solutions tailored to the specific needs of individual doors and windows. For example, large commercial doors and windows are significantly larger and heavier than typical household ones, necessitating custom rollers with greater load-bearing capacity. Or, for example, doors and windows with curved tracks, standard rollers simply won't fit. Customized rollers can adjust their shape to the curve of the track to ensure a perfect fit. This "customization" fundamentally addresses the problem of generic rollers being incompatible, ensuring the rollers and windows are perfectly matched from the outset, laying the foundation for optimal performance. Let's talk about the core advantage of "low noise," which directly improves the user experience of doors and windows. The constant creaking sound of opening and closing windows at home can be extremely annoying, especially in quiet spaces like bedrooms and studies. Customizable low-noise rollers are designed with meticulous attention to detail. They utilize inherently noise-reducing materials like nylon and modified plastics to reduce the harshness of metal friction. They also incorporate high-precision bearings, such as the previously mentioned 628ZZ model, to ensure smoother rotation and reduce noise at the source. Customized models can also adjust the fit between the roller and track based on the sealing requirements of the door or window, eliminating vibration noise caused by excessive gaps. This results in a quieter indoor environment when the window is closed.

Beyond noise reduction, customizable low-noise sliding rollers improve door and window performance in multiple ways. For example, when it comes to smoothness, the roller diameter and rolling resistance are precisely adjusted during customization based on the track width and weight of the door or window. Whether it's a residential window weighing dozens of kilograms or a commercial door weighing hundreds of kilograms, they slide into place effortlessly, without any snagging or shifting. Regarding durability, custom models feature materials tailored to the environment in which they are used. For example, rust-resistant stainless steel rollers are used for humid bathrooms and balconies, while wear-resistant reinforced materials are used for busy shopping mall entrances. This prevents the rollers from breaking and extends the overall lifespan of the door or window by 3-5 years.

Another crucial aspect is energy efficiency. Many people may not realize that rollers also play a role in energy efficiency. Customizable rollers can precisely adjust their height and fit, ensuring a seamless fit between closed doors and windows, eliminating gaps that could leak air or water. This prevents hot or cold air from escaping during summer air conditioning and winter heating, reducing energy consumption by 15%-20%, saving both money and the environment. For large-scale windows and doors like shopping malls and office buildings, this can significantly save electricity costs over the long term.

Whether for residential or commercial use, choosing the right customizable, low-noise sliding rollers is crucial. While less visible than the door or window frame, they are crucial components that influence user experience and performance. Their customizable design allows them to perfectly adapt to different scenarios, while their low noise levels enhance comfort. Combined with their smoothness, durability, and energy efficiency, they are a perfect choice for easy-to-use and worry-free windows and doors.

Benefits of Using Low-Noise Sliding Rollers in Residential and Commercial Sliding Systems

1. Stable and Quiet Sliding System

- The low-noise sliding rollers are equipped with high-precision bearings and feature a sealed design. These two features significantly reduce friction and noise. Whether opening or closing windows or doors, the operation is incredibly smooth, without the unpleasant "creaking" noises typical of older rollers. Imagine this: if you had this at home, opening and closing windows would be quiet, allowing for quiet rest and watching TV. Similarly, if you used it in a shopping mall or office, customers would enjoy a comfortable stroll while employees wouldn't be disturbed by noise. Who wouldn't want such a peaceful environment?

2. Extremely Durable, No Frequent Trouble

- Using high-quality materials and advanced manufacturing techniques, it can withstand heavy loads and provide long-term stability. Even in a shopping mall door, which is opened and closed dozens or even hundreds of times a day, it maintains a smooth glide and resists wear. This eliminates the need for frequent roller repairs and replacements, saving significant hassle and cost. Whether for home or commercial use, this is a real peace of mind. 3. Comfortable to Use and Energy-Saving

- Because of reduced friction, sliding is effortless, creating a truly pleasant experience. Furthermore, reduced friction indirectly saves energy—for example, windows at home not only open and close smoothly, but also provide better sealing. This means the heating runs less frequently in winter and the air conditioning lasts longer in summer, saving on electricity bills. For large spaces like shopping malls, reducing noise levels leads to greater customer and employee satisfaction, while also reducing operating costs for businesses—a truly two-pronged approach.

Step-by-Step Installation Guide for Customizable Low-Noise Sliding Rollers

|

Step-by-Step Installation Guide for Customizable Low-Noise Sliding Rollers |

|

|

1. Pre-Installation Checklist |

|

|

Essential Tools: |

A level, screwdriver, measuring tape, drill, and screws. |

|

Ensure Correct Roller Size: |

Verify that the sliding rollers are compatible with your door or window size to avoid future issues. |

|

Track and Roller Alignment: |

Double-check the size and alignment of the tracks to ensure proper installation and smooth sliding. |

|

2. Installing the Tracks for Sliding Doors/Windows |

|

|

Mark the Placement of Tracks: |

Measure the distance from the wall or ceiling to ensure the tracks are level. Mark the drill points. |

|

Drill Holes and Fix Tracks: |

Drill the necessary holes, making sure they align with the marks. Use screws to attach the tracks securely, ensuring they are level and stable. |

|

3. Installing the Low-Noise Sliding Rollers |

|

|

Insert the Rollers into the Track: |

Carefully insert the low-noise sliding rollers into the track. Ensure that each roller is firmly seated in the track without any gaps or misalignment. |

|

Adjust Roller Height: |

Many low-noise sliding rollers are customizable. Adjust their height according to the door/window weight and desired sliding speed. |

|

Secure the Rollers: |

Tighten the screws or bolts securing the rollers in place. |

|

4. Adjustments and Alignment |

|

|

Test the Door/Window Movement: |

Open and close the door/window to ensure smooth and silent operation. |

|

Fine-tune the Rollers: |

If necessary, make small adjustments to the roller height or track placement to achieve the perfect sliding movement. |

|

5. Final Checks and Ongoing Maintenance |

|

|

Check Roller Functionality: |

Ensure the rollers are operating smoothly and quietly. |

|

Lubrication: |

Apply lubricant to the rollers and track to minimize friction and prolong their lifespan. |

|

Regular Inspection: |

Perform routine checks and maintenance to ensure the system continues to operate optimally. |

Durability and Maintenance Tips for Low-Noise Sliding Rollers in High-Traffic Areas

1. The Impact of High-Frequency Use on Sliding Rollers

- In environments with frequent opening and closing, sliding rollers are subject to significant wear. Frequent use can cause fatigue in the roller material, resulting in rough sliding or noise. Therefore, it is crucial to select durable, low-noise sliding rollers suitable for frequent use.

2. Tips for Extending the Life of Low-Noise Sliding Rollers

- Using Wear-Resistant Materials: High-quality wear-resistant materials such as polyurethane and nylon can effectively improve the durability of sliding rollers. These materials can withstand high loads and frequent friction.

- Adopting Advanced Sealing Technology: The double-layer sealing design effectively prevents dust and moisture from entering the roller interior, thus preventing sliding problems.

- Selecting High-Load Rollers: For sliding door and window systems that must support heavy loads, selecting rollers with high load capacity is crucial to ensure stability in high-frequency use.

3. Regular Roller Maintenance Recommendations

- Cleaning and Lubrication: Regularly clean the roller surface and sliding track to prevent dust and debris that may affect sliding performance. Lubricate the rollers regularly to reduce friction and extend their service life.

- Inspection and Adjustment: Regularly inspect the rollers for wear, deformation, or damage. Replace any problems promptly and ensure the rollers are properly installed.

4. Solutions to Common Problems

- Problem 1: Unstable Sliding: Check the track for flatness and the rollers for proper operation. If necessary, readjust the rollers or clean the track.

- Problem 2: Increased Noise: Increased noise may be due to roller wear or an uneven track. Maintain the rollers regularly, keeping them lubricated and clean.

Customizable low-noise sliding rollers play a significant role in enhancing the overall performance and efficiency of window and door systems. By reducing friction and ensuring smooth, quiet operation, these rollers contribute to a more reliable and durable system. Proper installation and regular maintenance help extend the lifespan of the rollers, minimizing the need for repairs and ensuring long-term functionality.

At Hune, we focus on producing high-quality sliding window/door rollers designed to meet the specific needs of various sliding systems. These rollers are engineered for precision and durability, making them an essential component for improving the operation of both residential and commercial sliding doors and windows.

English

English  Español

Español  日本語

日本語