Over the past few years, we have diligently pursued higher standards to enhance our product quality, aiming to deliver increased convenience and a better user experience.

-

0㎡Plant Area

0㎡Plant Area -

0+Staff

0+Staff -

0Established in

0Established in -

0+Exporting Countries

0+Exporting Countries

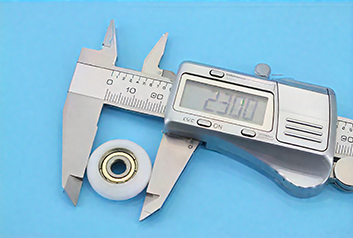

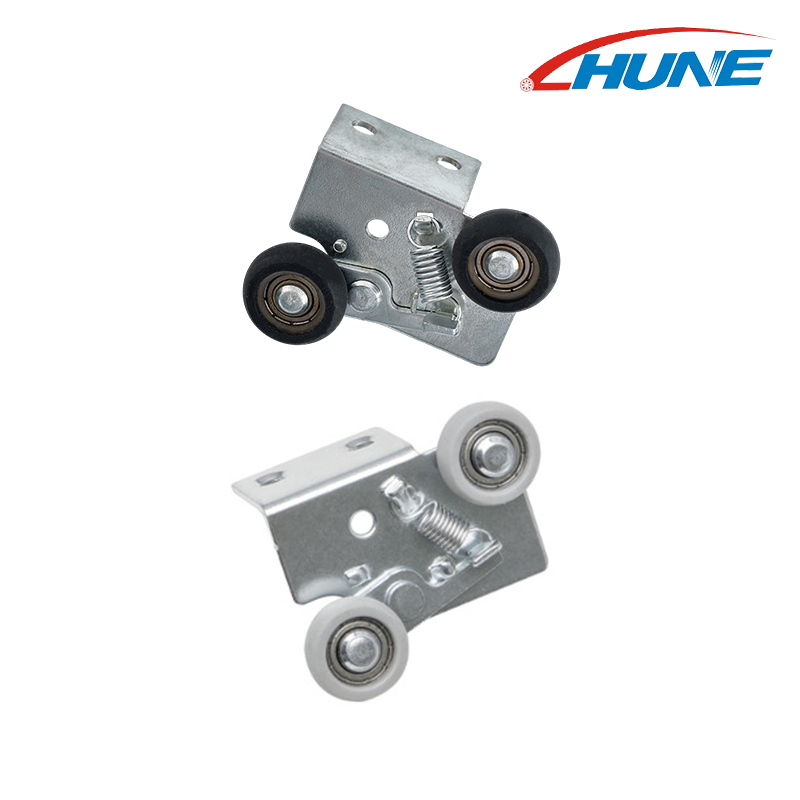

Adjustable Sliding Door Anti‑Sway Guide Roller with Screws – Noise‑Reducing, Heavy Duty Bottom Guide Wheel for Interior/Exterior Sliding Doors

Sliding doors are supposed to feel effortless: a clean line, a gentle pull, a quiet glide. Yet many doors don't fail dramatically—they degrade into everyday irritation. The panel starts to sway. It taps the wall. It chatters on the track. It develops that unmistakable rattle that announces itself at the worst times, like late-night kitchen raids or early-morning closet runs. An adjustable anti-sway bottom guide roller is a small part that solves a surprisingly big problem: keeping a sliding door stable, aligned, and quiet—whether it's inside the home or exposed to tougher exterior conditions.

Why "Anti‑Sway" Matters More Than People Think

Most people assume the top hardware does all the work. In many sliding door setups, the door is suspended or primarily supported from above, and the bottom is "just guidance." But guidance is the difference between a door that feels premium and one that feels improvised.

Sway shows up when the door can move laterally as it slides—rocking or drifting as the panel travels. That side-to-side movement creates a chain reaction: misalignment increases friction, friction increases noise, and noise often signals wear. Over time, the door begins to behave like it's fighting the track.

An sliding door anti-sway guide roller is designed to constrain that lateral movement. It keeps the panel's path consistent, reducing the tiny collisions and vibrations that become audible and annoying.

The Bottom Guide Roller's Real Job

A bottom guide isn't merely a wheel. In practice, it serves three essential functions:

- Stability: It helps prevent the door from wobbling as it starts moving, stops, or changes direction. That wobble is what causes “door slap”—the edge contacting the jamb or wall.

- Alignment: It keeps the panel tracking straight, so the top hardware isn't forced to compensate. Better alignment means smoother travel and less uneven stress on rollers and hangers.

- Protection: It reduces scraping and edge wear. When a door sways, the lower corners can drag on guides, thresholds, or floor surfaces, slowly grinding down finishes and creating debris.

For interior doors, the goal is often comfort and quiet. For exterior sliding doors, the goal expands to durability and consistent performance through temperature changes, dust, and heavier panels.

Adjustable Design: Quiet Performance Starts with Fit

"Adjustable" sounds like a convenience feature, but it's really a performance feature. No doorway is perfect. Frames settle. Floors aren't always level. Seasonal shifts can change clearances by small amounts that make a big difference in how a door behaves.

An adjustable guide roller allows you to dial in the fit so the roller contacts the panel (or guide channel) with the right pressure—firm enough to control sway, not so tight that it adds drag. That tuning does two things at once:

- It reduces vibration by preventing loose play that causes chatter.

- It reduces friction by avoiding over-clamping or misalignment.

In other words, adjustment helps you land in the sweet spot: stable and quiet, but still effortless.

Noise Reduction: Where the Sound Actually Comes From

Sliding door noise usually isn't one single issue. It's a mix of micro-impacts, vibration, and friction. A bottom guide roller helps with all three.

When the door sways, it taps. When it taps, it resonates through the panel and frame—especially with hollow-core doors, aluminum frames, or large glass surfaces. A guide roller reduces those taps by keeping the door centered.

Then there's track noise: if alignment is off, the top rollers can ride unevenly, creating a repeating rumble or scraping sound. Stabilizing the bottom reduces the load fluctuations at the top, which often lowers overall noise more than people expect.

Finally, a roller with a quality wheel material and smooth rotation reduces the squeak-and-grind effect that comes from sliding contact or cheap, sticky wheels.

Heavy Duty Isn't Just About Weight

"Heavy duty" should mean more than "it doesn't break." In a guide roller, heavy duty performance is about holding geometry under stress. A stable bracket resists bending. A well-made wheel resists flat spots. A solid axle or bearing surface resists wobble. And the mounting hardware needs to hold tight over time, especially when doors are frequently used or exposed to vibration.

For exterior applications, heavy duty also implies better tolerance for dust, grit, and moisture—conditions that accelerate wear and turn smooth movement into rough movement. A guide that maintains stability despite these factors doesn't just feel better; it extends the life of the entire sliding system.

Screws Included: Small Detail, Big Difference

Including screws seems basic, but it matters for installation success. The right screws reduce stripping, improve bite into common substrates, and help the guide stay aligned instead of slowly rotating or shifting after repeated use.

More importantly, providing a complete mounting solution encourages correct installation—because many “mystery problems” in sliding doors come from hardware that was installed with whatever fasteners happened to be in a drawer. A guide roller that's slightly loose is often worse than none at all: it can introduce noise and uneven wear.

Where This Guide Roller Fits Best

This type of adjustable bottom guide wheel is a practical upgrade for:

- Interior barn-style doors that sway when opened quickly or stopped abruptly

- Closet doors that rattle or misalign over time

- Room dividers where quiet operation matters

- Exterior sliding doors that need stability under wind pressure or frequent use

It's also ideal when you've already replaced top rollers but the door still feels unstable—because the bottom guidance is the missing half of the equation.

A truly smooth sliding door isn't the result of chance—it comes from stable tracking, minimal vibration, and clean guidance at the base. An adjustable anti-sway bottom guide roller addresses the real culprits behind wobble and rattling by keeping the panel aligned and preventing side-to-side drift. When the door stays centered, it rolls with less resistance, produces less chatter, and feels more controlled with every open and close. The difference is subtle in appearance but obvious in use: quieter motion, fewer jolts, and a more "finished" feel throughout the space. That's why Hune focuses on guide rollers built to perform, not just fit.

English

English  Español

Español  日本語

日本語